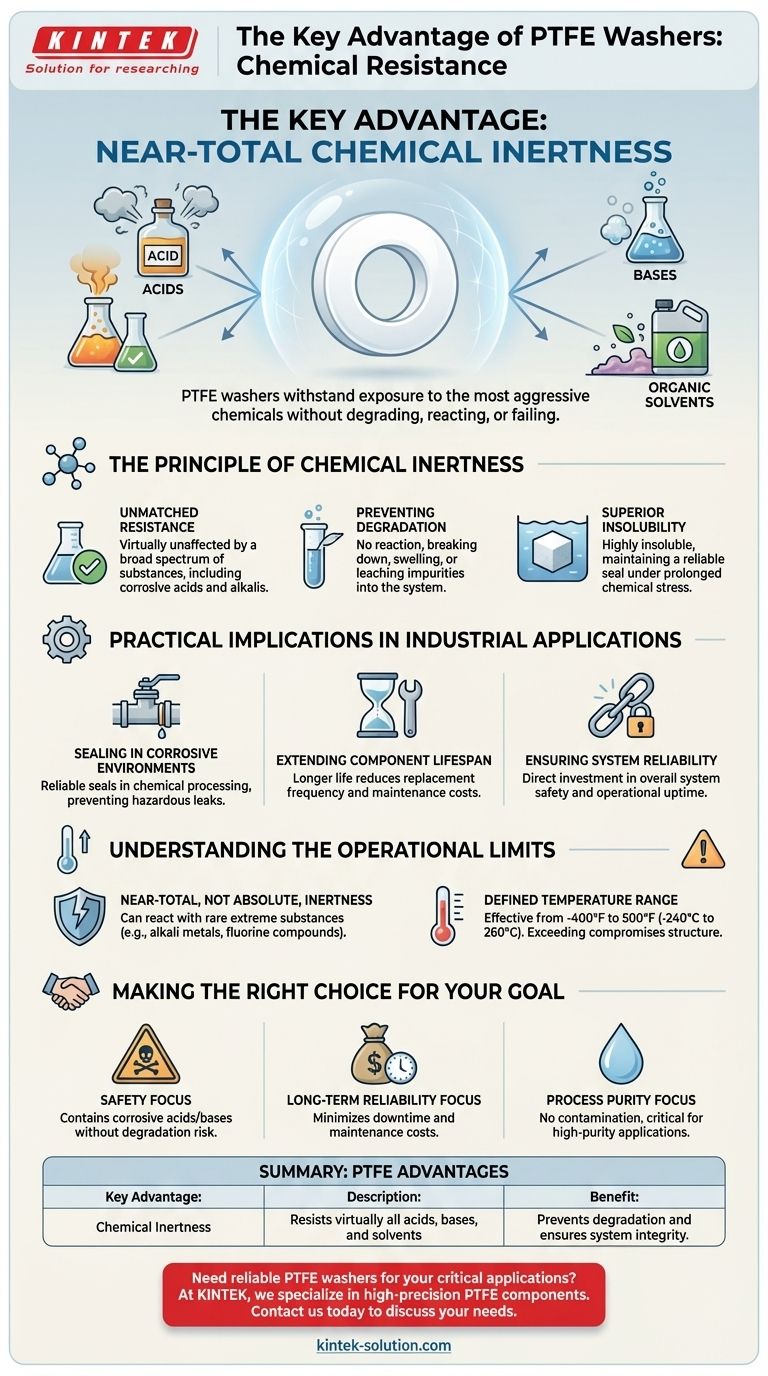

The key advantage of PTFE washers is their near-total chemical inertness. This property allows them to be exposed to the most aggressive and corrosive chemicals—including strong acids, bases, and organic solvents—without degrading, reacting, or failing.

The core value of PTFE's chemical resistance isn't just about surviving harsh conditions; it's about guaranteeing system integrity and reliability where nearly any other material would falter, preventing costly leaks, failures, and downtime.

The Principle of Chemical Inertness

Polytetrafluoroethylene (PTFE) is one of the most chemically resistant plastics known. This unique characteristic is not just a feature but the foundation of its value in critical applications.

Unmatched Resistance to a Broad Spectrum

PTFE is virtually unaffected by a wide array of substances. This includes corrosive acids, alkalis, and nearly all organic solvents that would quickly destroy other materials.

This broad-spectrum resistance makes it a default choice for multi-purpose systems that handle different types of chemicals.

Preventing Degradation and Contamination

Because PTFE is almost completely inert, it does not react with the materials it contacts. It will not break down, swell, or leach impurities into the system.

This ensures the purity of the process fluid and the structural integrity of the washer itself over long periods of exposure.

Superior Insolubility

PTFE is highly insoluble in most known solvents and chemicals. This prevents it from dissolving or weakening, maintaining a reliable seal even under prolonged chemical stress.

Practical Implications in Industrial Applications

The theoretical properties of PTFE translate directly into tangible benefits in demanding operational environments, making it indispensable in several key industries.

Sealing in Corrosive Environments

In chemical processing plants, laboratories, and industrial pipelines, PTFE washers provide a reliable seal that prevents leakage of hazardous materials. Their ability to withstand aggressive media ensures the safety and efficiency of the operation.

Extending Component Lifespan

By resisting chemical attack, PTFE washers maintain their physical properties and sealing capability far longer than other materials. This directly reduces the need for frequent replacements, minimizing maintenance costs and operational downtime.

Ensuring System Reliability

The failure of a simple component like a washer can lead to catastrophic system failure. Using PTFE in critical joints, flanges, and connections is a direct investment in the overall reliability and safety of the entire system.

Understanding the Operational Limits

While its chemical resistance is exceptional, it is essential to understand the context in which PTFE operates best. It is not a universal solution for every engineering problem.

Near-Total, Not Absolute, Inertness

PTFE is considered almost completely chemically inert. However, it can react with a few highly specialized and reactive substances, such as certain alkali metals and fluorine compounds under extreme temperature and pressure conditions.

For the vast majority of industrial chemicals, this limitation is purely academic.

Defined Temperature Range

The material's properties are maintained within a specific operating temperature range. The references note a typical range of -400°F to 500°F (-240°C to 260°C).

Exceeding this range can compromise the material's structural integrity, even if the chemical resistance remains.

Making the Right Choice for Your Goal

Selecting PTFE is a strategic decision based on the specific demands of your application.

- If your primary focus is safety in hazardous environments: Use PTFE for its unparalleled ability to contain corrosive acids, bases, and solvents without risk of material degradation.

- If your primary focus is long-term reliability: Choose PTFE to drastically reduce component failure, minimize system downtime, and lower maintenance costs over the equipment's lifecycle.

- If your primary focus is process purity: Select PTFE to ensure the washer does not react with or contaminate the media it is sealing, which is critical in laboratory and high-purity applications.

Ultimately, choosing PTFE washers is an investment in the long-term stability and resilience of your most critical systems.

Summary Table:

| Key Advantage | Description | Benefit |

|---|---|---|

| Chemical Inertness | Resists virtually all acids, bases, and organic solvents. | Prevents degradation and ensures system integrity. |

| Broad-Spectrum Resistance | Effective against a wide range of chemicals. | Ideal for multi-purpose systems. |

| Operational Temperature Range | Performs from -400°F to 500°F (-240°C to 260°C). | Reliable performance under extreme conditions. |

Need reliable PTFE washers for your critical applications?

At KINTEK, we specialize in manufacturing high-precision PTFE components, including seals, liners, and labware, for the semiconductor, medical, laboratory, and industrial sectors. Our expertise ensures your systems are protected against the most aggressive chemicals, preventing leaks, failures, and costly downtime.

We offer custom fabrication from prototypes to high-volume orders, prioritizing precision and durability. Contact us today to discuss your specific needs and enhance the safety and reliability of your operations.

Get a Quote & Discuss Your Project

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Customizable PTFE Seals Filter Holders for Versatile Applications

- Custom PTFE Bottles for Diverse Industrial Applications

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

People Also Ask

- Why is CNC machining preferred for Teflon parts over other methods? Unlock Precision & Complex Designs

- What are the future considerations for machining Teflon? Mastering Material Challenges with Smart Tech

- What are the main advantages of using PTFE parts in industrial applications? Unlock Unmatched Chemical Resistance and Reliability

- What are the key advantages of PTFE? Unmatched Performance for Extreme Environments

- Why is PTFE rod suitable for automotive applications? Boost Vehicle Performance & Durability