The durability of PTFE washers stems directly from their unique chemical inertness. Unlike materials that rely on sheer hardness, a Polytetrafluoroethylene (PTFE) washer’s longevity comes from its profound resistance to environmental degradation. It withstands corrosive chemicals, extreme temperatures, and wear from friction, making it a uniquely resilient component in demanding operational conditions.

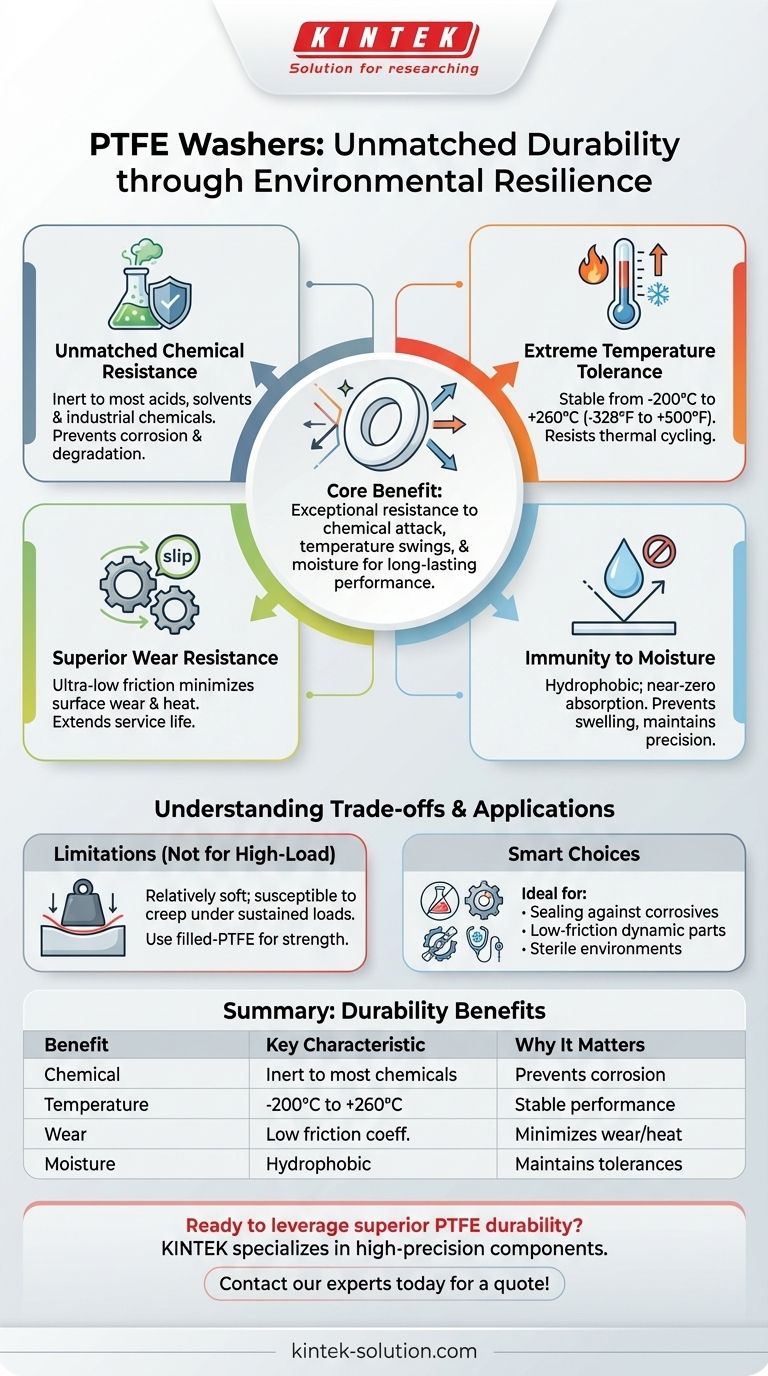

The core benefit of a PTFE washer is its exceptional environmental durability. Its ability to resist chemical attack, temperature swings, and moisture ensures long-lasting, stable performance in environments where most other materials would quickly fail.

The Core Pillars of PTFE Durability

To understand why PTFE washers are so durable, we must look beyond a simple definition of toughness and examine the material's fundamental properties. Its resilience is a combination of several key characteristics that work together.

Unmatched Chemical Resistance

PTFE is one of the most chemically inert polymers known. This means it does not react with the vast majority of industrial chemicals, acids, and solvents.

This property prevents corrosion and chemical degradation, which are common failure points for metal and other plastic washers. The material maintains its structural integrity even during prolonged exposure to aggressive substances.

Extreme Temperature Tolerance

A key factor in PTFE's durability is its remarkably wide operating temperature range, typically from -200°C to +260°C (-328°F to +500°F).

This stability prevents the material from becoming brittle at cryogenic temperatures or deforming at high heat. It ensures consistent mechanical properties and reliable performance under severe thermal cycling.

Superior Wear Resistance via Low Friction

PTFE has an extremely low coefficient of friction, one of the lowest of any solid material. This is the same property that gives non-stick cookware its signature quality.

In mechanical applications, this low friction minimizes surface wear between moving parts. Less friction means less abrasive force and less heat generation, directly contributing to a longer service life for both the washer and the components it contacts.

Immunity to Moisture

PTFE is hydrophobic, meaning it repels water and has a near-zero rate of moisture absorption.

This prevents the washer from swelling, changing its dimensions, or losing its mechanical properties in humid or submerged conditions. This stability is critical for maintaining precise tolerances in sensitive assemblies.

Understanding the Trade-offs

While PTFE's durability is exceptional, it is crucial to understand its limitations. Its resilience is environmental, not purely mechanical.

Not a High-Load Material

Standard PTFE is a relatively soft material. It does not possess the high compressive strength or load-bearing capacity of metal washers like steel or bronze.

In applications with extremely high bolt loads or constant pressure, pure PTFE can deform. For these scenarios, filled-PTFE composites (e.g., bronze-filled or glass-filled) are often used to enhance rigidity and strength.

Susceptibility to Creep

Under a sustained compressive load, PTFE can be subject to "creep," which is a slow, gradual deformation over time.

Engineers must account for this behavior in critical sealing or gasket applications where consistent pressure is essential for long-term performance.

Making the Right Choice for Your Application

Selecting the correct washer requires matching the material's strengths to the primary challenge of the environment.

- If your primary focus is sealing against corrosive chemicals: PTFE is an unparalleled choice due to its extreme chemical inertness.

- If your primary focus is a low-friction surface in extreme temperatures: PTFE's wide operating range and slick surface make it highly effective for dynamic applications.

- If your primary focus is high mechanical load-bearing: You should consider a metal washer or a filled-PTFE composite that enhances compressive strength.

- If your primary focus is a sterile, non-contaminating interface: PTFE's FDA approval and biocompatibility make it ideal for food, medical, and pharmaceutical use.

By understanding PTFE's unique profile of environmental resilience, you can confidently deploy it where it will provide unmatched long-term performance.

Summary Table:

| Durability Benefit | Key Characteristic | Why It Matters |

|---|---|---|

| Chemical Resistance | Inert to most chemicals, acids, and solvents. | Prevents corrosion and degradation, ensuring longevity in harsh environments. |

| Temperature Tolerance | Stable from -200°C to +260°C (-328°F to +500°F). | Maintains performance under extreme thermal cycling, preventing brittleness or deformation. |

| Wear Resistance | Extremely low coefficient of friction. | Minimizes surface wear and heat generation, extending the life of the washer and mating parts. |

| Moisture Immunity | Hydrophobic, near-zero moisture absorption. | Prevents swelling or dimensional changes, maintaining precise tolerances in humid or wet conditions. |

Ready to leverage the superior durability of PTFE washers in your application?

At KINTEK, we specialize in manufacturing high-precision PTFE components, including seals, liners, and custom washers, for the most demanding environments in the semiconductor, medical, laboratory, and industrial sectors. Our expertise ensures you get a component that delivers unmatched chemical resistance, thermal stability, and long-term reliability.

Whether you need a standard part or a custom-fabricated solution from prototype to high-volume production, we are here to help. Contact our experts today to discuss your specific requirements and get a quote!

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Customizable PTFE Seals Filter Holders for Versatile Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Volumetric Flasks for Advanced Scientific and Industrial Use

People Also Ask

- How does PTFE contribute to low friction and wear resistance? Achieve Superior Performance with Advanced Materials

- What are the key advantages of PTFE? Unmatched Performance for Extreme Environments

- What are the future considerations for machining Teflon? Mastering Material Challenges with Smart Tech

- What are the best practices for achieving tight tolerances in Teflon (PTFE) machining? Master Precision for Demanding Applications

- What are the key considerations when machining Teflon? Master Precision Machining for Soft Polymers