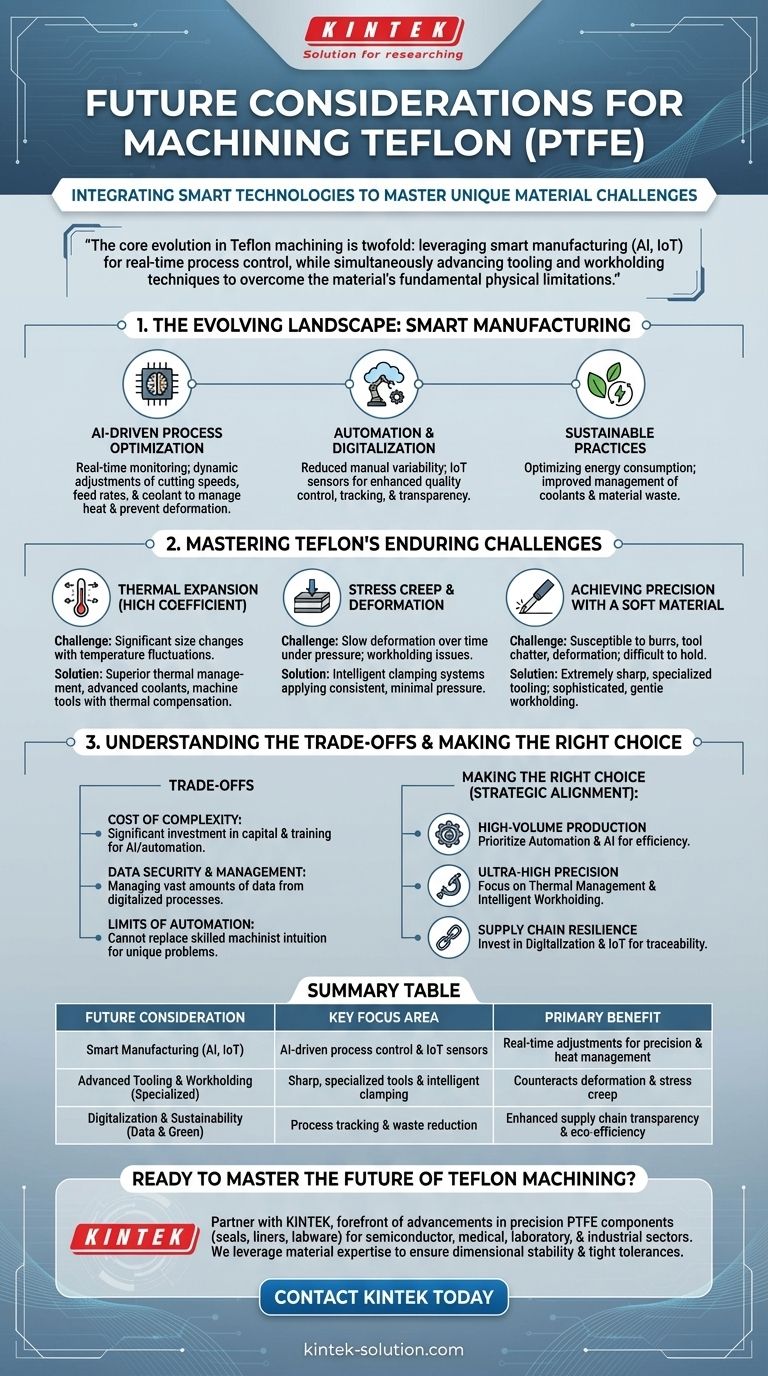

Looking forward, the future of machining Teflon (PTFE) isn't just about faster machines; it's about integrating smart technologies to finally master the material's unique and persistent challenges. Advances in automation, AI-driven process optimization, and digitalization will deliver greater precision and efficiency, but their true value lies in their ability to counteract Teflon's inherent tendency to expand, deform, and creep under stress.

The core evolution in Teflon machining is twofold: leveraging smart manufacturing (AI, IoT) for real-time process control, while simultaneously advancing tooling and workholding techniques to overcome the material’s fundamental physical limitations.

The Evolving Landscape: Smart Manufacturing

The next generation of machining excellence will be driven by data and intelligent systems. These technologies are poised to solve problems that have traditionally required extensive operator experience.

AI-Driven Process Optimization

Artificial intelligence and machine learning will monitor machining operations in real-time. These systems can dynamically adjust cutting speeds, feed rates, and coolant flow to manage heat generation and prevent deformation as it happens.

This moves beyond static setup parameters to a responsive, intelligent machining environment tailored to each specific part.

Automation and Digitalization

Increased automation will reduce the variability that comes from manual handling, which is critical for a slippery material like Teflon.

Digitalization, including the use of IoT sensors on machines, will enhance quality control and create a more transparent supply chain, allowing for better tracking and process validation from raw material to finished component.

A Push Towards Sustainable Practices

Future strategies will also emphasize sustainability. This includes optimizing energy consumption during machining and improving the management of coolants and material waste, aligning manufacturing processes with broader environmental goals.

Mastering Teflon's Enduring Challenges

Technology evolves, but the physics of the material remain. The primary considerations for the future are still rooted in overcoming Teflon's core properties, which cause the most common machining failures.

The Problem of Thermal Expansion

Teflon has a very high coefficient of thermal expansion. Even small temperature changes during machining can cause the material to expand or contract significantly, making it incredibly difficult to hold tight tolerances.

Future solutions will focus on superior thermal management, from advanced coolant systems to machine tools that compensate for temperature fluctuations.

Countering Stress Creep and Deformation

Teflon is prone to stress creep, meaning it slowly deforms over time when under pressure. This is a major challenge for workholding, as clamping pressure that is adequate at the start of a job may lead to part deformation by the end.

Intelligent clamping systems that can apply consistent but minimal pressure will be a key area of development.

Achieving Precision with a Soft Material

Because Teflon is soft, it is susceptible to burrs, tool chatter, and deformation under cutting pressure. Its low coefficient of friction also makes it slippery and difficult to hold securely without marring the surface.

This necessitates the continued use of extremely sharp, specialized tooling and the development of more sophisticated workholding solutions that grip firmly but gently.

Understanding the Trade-offs

While advanced technology offers powerful solutions, it introduces new complexities and considerations that must be managed.

The Cost of Complexity

Integrating AI, IoT, and automation requires significant capital investment and a skilled workforce. The benefits of precision and efficiency must be weighed against the cost and training required to implement and maintain these advanced systems.

Data Security and Management

A fully digitalized manufacturing process generates vast amounts of data. Ensuring the security of this data and developing systems to analyze it effectively is a critical challenge that accompanies the move to smart manufacturing.

The Limits of Automation

While automation can perfect repetitive tasks, it cannot easily replace the intuition of a skilled machinist. Diagnosing unique problems or handling custom, low-volume jobs will still require human expertise to guide and oversee the technology.

Making the Right Choice for Your Goal

As you plan for the future, your strategy should align with your primary operational objectives.

- If your primary focus is high-volume production: Prioritize investment in automation and AI-driven process optimization to maximize efficiency and repeatability.

- If your primary focus is ultra-high precision: Concentrate on advanced thermal management, specialized diamond tooling, and intelligent workholding systems to control for Teflon's material instability.

- If your primary focus is supply chain resilience: Invest in digitalization and IoT to improve traceability, quality control, and real-time production monitoring.

Ultimately, successfully machining Teflon in the future will depend on using technology to build a deep, responsive understanding of the material itself.

Summary Table:

| Future Consideration | Key Focus Area | Primary Benefit |

|---|---|---|

| Smart Manufacturing | AI-driven process control & IoT sensors | Real-time adjustments for precision and heat management |

| Advanced Tooling & Workholding | Sharp, specialized tools & intelligent clamping | Counteracts deformation and stress creep |

| Digitalization & Sustainability | Process tracking & waste reduction | Enhanced supply chain transparency and eco-efficiency |

Ready to Master the Future of Teflon Machining?

As the future of PTFE machining evolves with AI and smart technology, partnering with an expert becomes critical. At KINTEK, we are at the forefront of these advancements, manufacturing precision PTFE components (seals, liners, labware, and more) for the semiconductor, medical, laboratory, and industrial sectors.

We leverage deep material expertise and state-of-the-art fabrication to overcome Teflon's unique challenges—ensuring dimensional stability and tight tolerances in every part, from prototypes to high-volume orders.

Let's build your precision components with the technology of tomorrow. Contact KINTEK today to discuss your project needs.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Customizable PTFE Rods for Advanced Industrial Applications

People Also Ask

- What are the unique properties of PTFE? The 3 Pillars Driving Demand for High-Performance Parts

- What design considerations are important for custom PTFE parts? Design for Performance & Reliability

- What finishing techniques are effective for machined Teflon parts? Achieve Functional Performance and Dimensional Stability

- What are the unique properties of PTFE? Unlock Unmatched Performance in Demanding Applications

- What fabrication services are available for PTFE? Shearing, Stamping, Laser Cutting, Molding & Machining