PTFE(Teflon) Labware

Custom Machined Molded PTFE Teflon Parts Manufacturer for Laboratory ITO FTO Conductive Glass Cleaning Flower Basket

Item Number : PL-1013

Price varies based on specs and customizations

- Chemical Resistance

- Highly resistant to virtually all chemical solvents, including strong acids and alkalis

- Temperature Tolerance

- -180°C to +250°C

Shipping:

Contact us to get shipping details Enjoy On-time Dispatch Guarantee.

Why Choose Us

Easy ordering process, quality products, and dedicated support for your business success.

Introduction

KINTEK manufactures high-purity PTFE flower baskets (also known as Teflon® flower baskets or cleaning racks) specifically designed for industries requiring exceptional chemical resistance and contamination-free processing. Ideal for semiconductor, medical, laboratory, and industrial applications, these components ensure the integrity of your sensitive materials like silicon wafers, glass substrates (ITO, FTO), and other delicate parts.

Crafted from experimental-grade PTFE, our flower baskets boast excellent chemical stability, corrosion resistance, and operate reliably across a wide temperature range (-180°C to +250°C). Their non-adhesive, non-toxic, and physiologically inert properties make them perfect for handling delicate samples and ensuring process purity.

Customized Solutions for Your Specific Needs

At KINTEK, we understand that standard solutions don't always fit. We specialize in custom fabrication from prototypes to high-volume orders. Whether you need PTFE cleaning racks tailored for specific glass substrates, unique dimensions for labware, or specialized designs for industrial processes, we provide free design and drawing services based on your description or sketch. Our goal is to deliver precision-engineered components that meet your exact requirements.

Ready to optimize your process with custom PTFE components? Discuss your project with our experts today!

Key Features & Applications

- Superior Chemical Inertness: Highly resistant to virtually all chemical solvents, including strong acids and alkalis, ensuring sample purity and component longevity.

- Wide Temperature Tolerance: Performs consistently in extreme temperatures from -180°C to +250°C, suitable for demanding thermal processes.

- Non-Adhesive & Easy to Clean: PTFE's inherently non-stick surface prevents residue buildup and simplifies cleaning procedures.

- Safe & Contamination-Free Handling: Ideal for sample digestion, pickling, boiling, drying, and long-term storage of standard solutions, organic solvents, and highly corrosive samples in laboratories.

- Critical for Specialized Industries:

- Semiconductor & Photovoltaic: Essential for cleaning and handling delicate silicon wafers, ITO/FTO glass, and other components without causing damage or contamination.

- Laboratory & Scientific Research: Vital for corrosion-free handling and storage of sensitive materials, ensuring data integrity.

- Medical & Industrial: Used where biocompatibility, purity, and resistance to harsh chemicals are paramount.

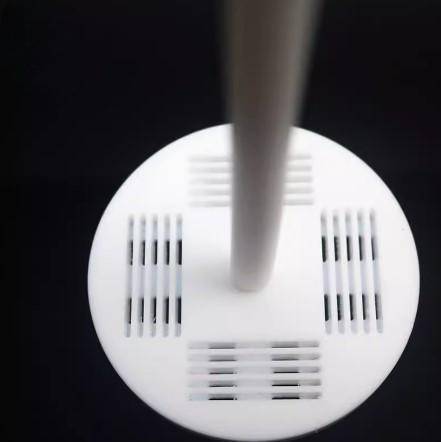

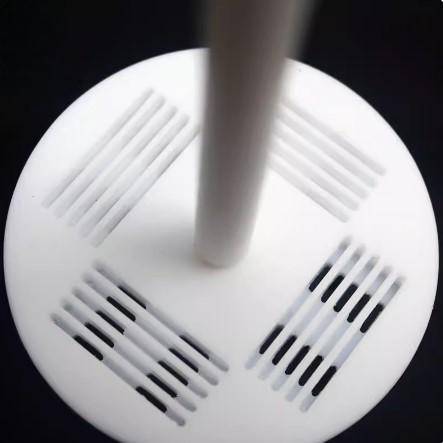

Detail & Parts

Visual examples of our precision PTFE cleaning rack designs and components.

Technical Specifications (Standard Examples)

Below are examples of standard configurations. We specialize in creating custom sizes to perfectly match your application needs.

| Diameter*groove width*groove length*applicable capacity | |

| 60mm*1.5mm*16mm*250ml beaker/20 pcs | 60mm*2.5mm*16mm*250ml beaker/20 pcs |

| 60mm*1.5mm*21mm*250ml beaker/20 pcs | 60mm*2.5mm*21mm*250ml beaker/20 pcs |

| 80mm*1.5mm*26mm*500ml beaker/20 pcs | 80mm*2.5mm*26mm*500ml beaker/20 pcs |

| 80mm*1.5mm*31mm*500ml beaker/20 pcs | 80mm*2.5mm*31mm*500ml beaker/20 pcs |

| 90mm*2.5mm*41mm*1000ml beaker/22 pcs | |

Don't see your required dimensions? The products we show are examples; custom sizes are our specialty and available upon request. Contact us via the form below to get a quote for your custom PTFE flower basket or cleaning rack.

Trusted by Industry Leaders

FAQ

What Are The Main Applications Of PTFE Parts?

What Are The Main Applications Of PTFE Components?

What Are The Main Applications Of PTFE Discs?

What Are The Main Applications Of PTFE Gaskets?

What Are The Main Applications Of PTFE Labware?

What Are The Main Applications Of PTFE Rings?

What Are The Common Applications Of PTFE Barrels?

What Are The Main Applications Of PTFE Rollers?

What Are The Common Applications Of PTFE Seal Rings?

What Are The Main Applications Of PTFE Brushes?

What Are The Main Applications Of PTFE Glands?

What Are The Main Applications Of Teflon Seals?

What Are The Common Applications Of Teflon Balls?

What Are The Main Applications Of Custom Teflon Parts?

What Are The Main Applications Of Custom PTFE Products?

What Are The Key Features Of PTFE?

What Are The Key Features Of PTFE Components?

What Are The Key Features Of PTFE Discs?

What Are The Key Features Of PTFE Gaskets?

What Are The Key Features Of PTFE Labware?

What Are The Key Features Of PTFE Rings?

What Are The Key Features Of PTFE Barrels?

What Are The Key Features Of PTFE Rollers?

What Are The Features Of A Spring PTFE Sealing Ring?

What Are The Key Features Of PTFE Brushes?

What Are The Key Features Of PTFE Glands?

What Are The Key Features Of Teflon Seals?

What Are The Key Features Of Teflon Balls?

What Are The Key Features Of Custom Teflon Parts?

What Are The Key Features Of PTFE That Make It Suitable For These Applications?

How Do PTFE O-ring Seals Work?

What Are The Key Components Of PTFE (Polytetrafluoroethylene)?

How Do PTFE Discs Work In Sealing Applications?

What Is The Principle Behind PTFE Gaskets?

What Makes PTFE Suitable For Labware?

How Are PTFE Rings Manufactured?

How Does A PTFE Lined Butterfly Valve Work?

How Are PTFE Rollers Manufactured?

How Does A PTFE Lined Butterfly Valve Operate?

What Is The Principle Behind PTFE Brushes?

How Do Teflon Seals Work In Harsh Environments?

What Are The Technical Specifications Of Teflon Balls?

What Are The Advantages Of Using Custom Teflon Parts?

How Is PTFE Processed Into Custom Parts?

What Are The Advantages Of Using PTFE Parts?

What Are The Advantages Of Using PTFE Components?

What Are The Advantages Of Using PTFE Discs?

What Are The Advantages Of Using PTFE Gaskets?

What Are The Advantages Of Using PTFE Labware?

What Are The Advantages Of Using PTFE Rings?

What Are The Advantages Of Using PTFE Barrels?

What Are The Advantages Of Using PTFE Rollers?

What Are The Advantages Of Mechanical Seals With PTFE Rings?

What Are The Advantages Of Using PTFE Brushes?

What Are The Advantages Of Using PTFE Glands?

What Are The Advantages Of Using Teflon Seals?

What Are The Advantages Of Using Teflon Balls?

Why Is Teflon Preferred For High-temperature Applications?

Why Is PTFE Suitable For CNC Machining?

Why Are PTFE Components Ideal For Chemical And High-temperature Applications?

Why Are PTFE Discs Preferred In High-temperature Environments?

How Are PTFE Gaskets Installed?

What Types Of PTFE Labware Are Available?

Why Are PTFE Rings Preferred In The Semiconductor Industry?

Why Are PTFE Barrels Suitable For Laboratory Use?

Why Are PTFE Rollers Preferred In The Chemical Industry?

Why Is PTFE Used In Medical Applications?

Are PTFE Brushes Safe For Food And Medical Applications?

Are Custom PTFE Glands Available For Specific Applications?

Are Teflon Seals Environmentally Friendly?

Why Are Teflon Balls Preferred In Medical And Food Industries?

Can Custom Teflon Parts Be Used In The Food And Beverage Industry?

Why Is PTFE Preferred In The Medical And Food Industries?

What Types Of PTFE Parts Are Commonly Manufactured?

How Do PTFE Components Perform In Cryogenic Conditions?

Are PTFE Discs Resistant To Chemicals?

Are PTFE Rings Suitable For Medical Applications?

Can PTFE Rollers Be Customized For Specific Applications?

How Does The Chemical Resistance Of PTFE Brushes Benefit Industrial Applications?

Can Teflon Balls Be Customized For Specific Applications?

What Makes Teflon Suitable For Electrical Insulation?

What Types Of Custom PTFE Products Are Available?

What Makes PTFE Discs Non-stick?

What Makes PTFE Brushes Suitable For High-temperature Environments?

Can PTFE Discs Be Used In Electrical Applications?

Why Are PTFE Brushes Preferred For Electrical Insulation?

How Do PTFE Discs Perform In Low-temperature Environments?

Are PTFE Discs Customizable For Specific Applications?

4.9 / 5

Incredible precision and durability! These PTFE parts have transformed our lab workflow.

4.8 / 5

Fast delivery and top-notch quality. Exactly as described, highly recommend!

4.7 / 5

Exceptional value for money. The Teflon parts are flawless and perform brilliantly.

4.9 / 5

Superior craftsmanship! These parts are a game-changer for our conductive glass cleaning.

4.8 / 5

Reliable and efficient. The PTFE parts withstand high temperatures without any issues.

4.9 / 5

Perfect fit and finish. The customization options are fantastic!

4.7 / 5

Great product at a reasonable price. The durability is impressive.

4.9 / 5

High-tech and high-quality. These parts have exceeded our expectations.

4.8 / 5

Speedy delivery and excellent customer service. The parts are flawless.

4.9 / 5

Precision engineering at its best. These PTFE parts are worth every penny.

4.7 / 5

Durable and reliable. Perfect for our laboratory needs.

4.9 / 5

Outstanding performance. The Teflon parts are a must-have for any lab.

4.8 / 5

Excellent quality and fast turnaround. Highly satisfied with the purchase.

4.9 / 5

Innovative design and superior materials. These parts are a cut above the rest.

4.7 / 5

Great value and performance. The PTFE parts are exactly what we needed.

4.9 / 5

Perfect for delicate lab work. The precision and quality are unmatched.

REQUEST A QUOTE

Our professional team will reply to you within one business day. Please feel free to contact us!

Related Products

Custom PTFE Parts Manufacturer for Teflon Containers and Components

High-precision PTFE containers for labs & industry. Chemical-resistant, customizable sizes. Ideal for semiconductor, medical & lab applications. Get a quote!

Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

KINTEK prioritizes precision production and offers custom fabrication from prototypes to high-volume orders.

Custom PTFE Teflon Parts Manufacturer Adjustable Height Flower Basket

High-purity PTFE adjustable height flower baskets for semiconductor and lab use. Chemical-resistant, non-stick, and customizable. Get yours today!

Custom PTFE Teflon Parts Manufacturer PTFE Cleaning Rack

High-purity PTFE flower baskets for labs & semiconductor use. Chemical-resistant, -180°C to +250°C, custom sizes available. Contact KINTEK today!

Custom PTFE Teflon Parts Manufacturer Conductive Glass Substrate Cleaning Rack

High-purity PTFE flower baskets for lab cleaning, resistant to chemicals & extreme temps. Custom designs available for semiconductor & medical applications.

Custom PTFE Bottles for Diverse Industrial Applications

High-purity PTFE bottles for chemical storage, resistant to acids & solvents. Wide/narrow mouth options, leak-proof, durable. Ideal for labs & industry.

Custom PTFE Square Trays for Industrial and Laboratory Use

Premium PTFE square trays for labs & industry. Chemical-resistant, non-stick, high-purity PTFE trays for semiconductors & medical use. Custom sizes available.

Custom PTFE Teflon Balls for Advanced Industrial Applications

Precision PTFE balls for chemical, medical & industrial use. High-performance, low-friction, chemical-resistant. Custom sizes available. Get a quote today!

Custom PTFE Volumetric Flasks for Advanced Scientific and Industrial Use

Premium PTFE volumetric flasks for labs – chemical-resistant, non-stick, precise measurements. Ideal for semiconductor, medical & analytical applications. Shop now!

Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

Discover the superior performance of our Polytetrafluoroethylene (PTFE) measuring cylinders, engineered for precision and resilience in demanding environments.

Customizable PTFE Crucibles for Laboratory and Industrial Applications

High-purity PTFE crucibles with lids for labs. Chemical-resistant, non-stick, and durable. Ideal for sample digestion, AA, ICP-MS. Custom sizes available.

Custom PTFE Sleeves and Hollow Rods for Advanced Applications

High-performance PTFE hollow rods & sleeves for chemical resistance, thermal stability, and low friction. Custom sizes available. Contact KINTEK today!

PTFE Deep Evaporating Dishes Customizable Laboratory and Industrial Solutions

High-quality PTFE deep evaporating dishes for labs. Chemical-resistant, non-stick, and customizable. Ideal for sample handling. Get yours now!

Customizable PTFE Seals Filter Holders for Versatile Applications

Enhance filtration with KINTEK's PTFE-sealed filter holders for leak-proof, chemical-resistant performance in labs and industries. Explore now!

Custom PTFE Shallow Evaporating Dishes for Diverse Applications

High-purity PTFE shallow evaporating dish for labs. Chemical-resistant, non-stick, ideal for sample evaporation. Custom sizes available. Order now!

PTFE Chemical Solvent Sampling Spoon

Discover our high-purity PTFE (Polytetrafluoroethylene, commonly known as Teflon) Sampling Spoons, meticulously engineered for the safe, precise, and contamination-free handling of chemicals, solvents, powders, and various samples.

Custom PTFE Evaporating Dishes for Diverse Applications

High-purity PTFE evaporating dishes for labs, resistant to acids & solvents. Non-stick, durable, ideal for sample prep. Custom sizes available. Order now!

Customizable PTFE Three Neck Flasks for Advanced Chemical Applications

Our high-performance Three-Neck Round-Bottom Flasks are expertly crafted from pure Polytetrafluoroethylene (PTFE), a material renowned for its exceptional properties, making it ideal for demanding laboratory and industrial environments.

Custom PTFE Microwave Digestion Vessels for Demanding Applications

High-purity PTFE microwave digestion vessels for safe, contamination-free sample prep. Ideal for ICP-MS, AAS, and trace analysis. Custom sizes available.

Related Articles

Your "Inert" PTFE Component Might Be the Real Source of System Failure

Inconsistent results? Learn why standard PTFE components fail under stress and how precision-fabricated, application-specific grades are the key to reliability.

Why Your High-Performance PTFE Parts Fail—And Why It's Not the Material's Fault

Discover the hidden reason your critical PTFE components fail. It's not the material, but the fabrication. Learn how to get reliable parts.

When "Chemically Inert" Isn't Enough: The Hidden Cause of PTFE Component Failure

Discover why standard PTFE components fail in critical applications, even with 'safe' chemicals. Learn the hidden role of fabrication quality and how to prevent costly downtime.

The Hidden Risk of PTFE: Why Your Go-To Material Is Now a Liability—And What to Do About It

Discover the hidden regulatory and performance risks of standard PTFE components. Learn why a strategic material choice is crucial for future-proofing your products.

The Geometry of Slipperiness: Why PTFE is the Invisible Margin of Victory

Explore how the molecular properties of PTFE reduce friction to enhance performance in baseball and precision industrial applications.

Beyond Sanitization: Why Your Material Choice Is the Real Key to Preventing Contamination

Recurring contamination in food & pharma isn't a process failure, but a material failure. Discover why PTFE is the key to lasting hygiene and uptime.

The PTFE Paradox: Why the 'Perfect' Material Fails—And How to Make It Work

Your high-performance parts fail despite using advanced materials like PTFE. Discover the hidden design flaw and how expert fabrication unlocks true reliability.

The Physics of a Perfect Fit: How PTFE Eliminates an Athlete's Hidden Distractions

Discover how PTFE's unique physics enhances athletic performance by ensuring a secure fit and maintaining traction, eliminating critical distractions.

The Asymmetric Cost of Failure: Why Precision PTFE Is Your Last Line of Defense

Learn how PTFE components save money not by being reusable, but by preventing catastrophic analytical failures and mitigating invisible financial risks.

The PTFE Trap: Why Your Team Is Debating the Wrong Question About "Forever Chemicals"

Confused by the PTFE vs. PTFE-free debate? Learn why the real risk isn't the material itself but its lifecycle, and how to choose the right component.

The Physics of Failure: Where Metal Fails, PTFE Prevails

PTFE components aren't just parts; they're solutions for high-friction, chemical, and sterile environments where traditional materials fail.

That Ghost Peak in Your Data? It’s Not Your Fault.

Frustrated by inconsistent results in pharmaceutical analysis? Discover the hidden cause of contamination and how precision PTFE components ensure data integrity.