It’s a scenario playing out in engineering departments worldwide. The design for your new flagship product is locked in. It’s built around reliable, industry-standard PTFE components—the safe, default choice for decades, known for its chemical inertness and low friction.

Then, a question arrives from your European sales team or a major customer: “Can you confirm this product is PFAS-compliant?”

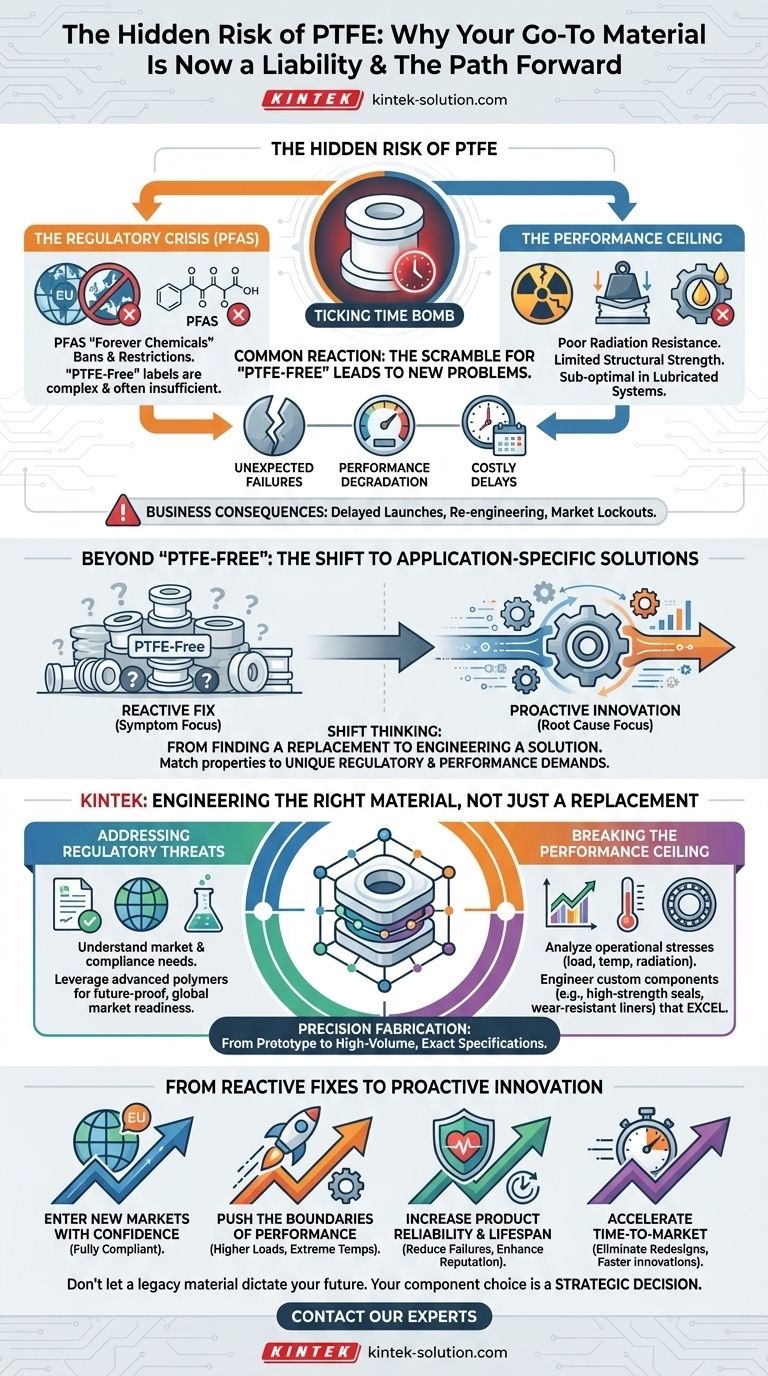

Suddenly, that “safe” design choice feels like a ticking time bomb. Your launch schedule, your market access, and your product's reputation are all at risk.

The Scramble for "PTFE-Free": A Widening Gap Between Hope and Reality

This isn't an isolated incident. Across the medical, semiconductor, and industrial sectors, engineers and product managers are facing the same unnerving challenge. The knee-jerk reaction is to search for any component labeled "PTFE-free" and swap it in, hoping for a quick fix.

But this frantic scramble often leads to more problems:

- Unexpected Failures: A new "PTFE-free" bushing, not properly matched to the application, wears out prematurely in a high-load environment.

- Performance Degradation: A replacement seal, lacking PTFE's unique properties, introduces friction that compromises the precision of a laboratory instrument.

- Costly Delays: The search for a viable alternative pushes project timelines back by months, as teams struggle to validate materials that meet both performance and regulatory standards.

The business consequences are severe and tangible. We're talking about delayed product launches, expensive re-engineering cycles, and, in the worst-case scenario, being locked out of critical markets like the European Union entirely. The attempt to solve one problem creates a cascade of new ones, because the focus is on the symptom—the material name—not the root cause.

Unmasking the Real Problem: It's Not Just a Material, It's a Mismatch

For decades, PTFE has been an engineer's best friend. But the world has changed, and relying on it as a universal default has created a fundamental misalignment between the material and its modern operating environment. The real issue isn't that PTFE is "bad"; it's that it now carries two silent, business-critical risks.

The Regulatory Time Bomb: The PFAS Crisis

The most urgent threat is regulatory. PTFE is part of a chemical family known as per- and polyfluoroalkyl substances (PFAS). Due to their extreme persistence in the environment, these "forever chemicals" face mounting restrictions and outright bans globally.

This is why simply finding a "PTFE-free" label is not enough. These regulations are complex and evolving. Choosing the wrong alternative could mean you’re still non-compliant. The common "fix" fails because it doesn't address the core challenge: navigating a complex chemical regulatory landscape.

The Performance Ceiling: When "Good Enough" Fails

The second risk has always been there, but is now magnified by the demands of modern technology. While PTFE is an excellent all-rounder, it was never the best choice for every job. It has known performance limits:

- Poor Radiation Resistance: It degrades and becomes brittle when exposed to radiation, making it unsuitable for many aerospace or nuclear applications.

- Limited Structural Strength: Compared to engineered composites, pure PTFE can deform under very high loads, compromising the integrity of critical pivot points in heavy machinery.

- Sub-optimal in Lubricated Systems: While it excels in dry-running conditions, some advanced polymers are specifically designed to offer longer life in environments flooded with oil or grease.

Trying to force PTFE into these applications is like using a family sedan for a Formula 1 race. It fails because the tool is mismatched to the task.

Beyond "PTFE-Free": The Shift to Application-Specific Solutions

To truly solve this problem, you must shift your thinking from "finding a replacement" to "engineering a solution." The goal is not just to eliminate PTFE; it's to select a material whose properties are precisely matched to your application's unique regulatory and performance demands.

This requires a deep understanding of polymer science and precision manufacturing. You need a partner who can look at your specific challenge—be it navigating PFAS rules for a medical device or increasing the load capacity of an industrial actuator—and design the ideal component from the ground up.

KINTEK: Engineering the Right Material, Not Just a Replacement

This is precisely where KINTEK's expertise lies. We are not just a parts supplier; we are material and fabrication specialists. Our process is built on the understanding that a component's success is determined long before the first production run.

- To address the regulatory threat, our team works with you to understand your market and compliance needs. We leverage our expertise in custom fabrication to select and manufacture components from a range of advanced polymers, ensuring your product is future-proof and ready for global markets.

- To break through the performance ceiling, we analyze your specific operational stresses—load, temperature, radiation, chemical exposure. We then engineer a custom component, whether it's a high-strength seal for a semiconductor chamber or a wear-resistant liner for a laboratory centrifuge, that is designed to excel where a generic part would fail.

Our precision production ensures that the final component, from a single prototype to a high-volume order, meets your exact specifications and delivers on its performance promise.

From Reactive Fixes to Proactive Innovation

Once you stop wrestling with the "PTFE problem," a world of new possibilities opens up. By partnering with a material expert, you move from a defensive, reactive position to a proactive, innovative one.

- Enter New Markets with Confidence: Launch products in the EU and other regulated regions, knowing your components are fully compliant.

- Push the Boundaries of Performance: Design equipment that operates under higher loads, in more extreme temperatures, or in environments that were previously off-limits.

- Increase Product Reliability and Lifespan: Reduce field failures and warranty claims by using components perfectly engineered for their task, enhancing your brand's reputation for quality.

- Accelerate Your Time-to-Market: Eliminate the risk of last-minute, compliance-driven redesigns and bring your innovations to customers faster.

Your component choice is no longer just a line item on a bill of materials; it's a strategic decision that can unlock new revenue, mitigate business risk, and become a source of competitive advantage. Don't let a legacy material choice dictate the future of your business. Let's discuss how the right material strategy can solve your immediate challenges and empower your next breakthrough. Contact Our Experts.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

- Custom PTFE Volumetric Flasks for Advanced Scientific and Industrial Use

- PTFE Chemical Solvent Sampling Spoon

Related Articles

- The Unseen Workhorse: Why PTFE Is the Default Choice for Impossible Problems

- Beyond "Non-Stick": Why Your PTFE Components Fail and How to Fix It for Good

- The Unseen Guardian: How PTFE's Molecular Shield Protects Our Most Critical Systems

- The Physics of a Perfect Fit: How PTFE Eliminates an Athlete's Hidden Distractions

- Your "Inert" PTFE Component Might Be the Real Source of System Failure