PTFE(Teflon) Labware

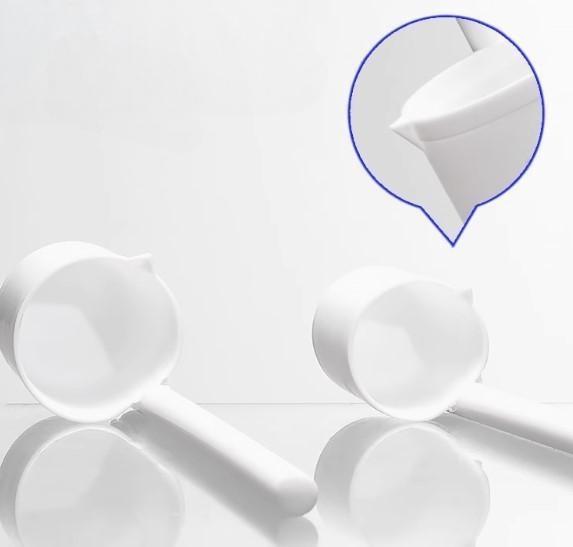

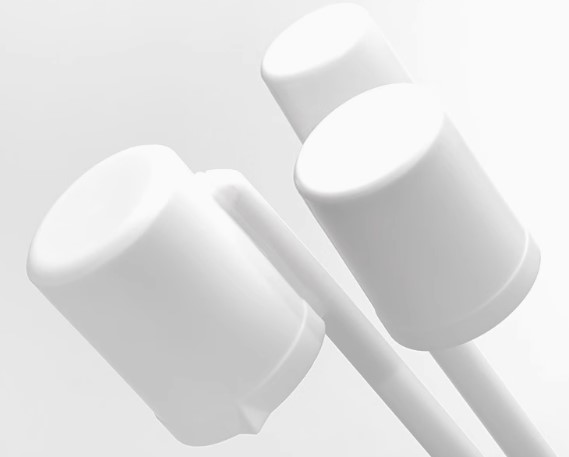

PTFE Chemical Solvent Sampling Spoon

Item Number : PL-1008

Price varies based on specs and customizations

Shipping:

Contact us to get shipping details Enjoy On-time Dispatch Guarantee.

Why Choose Us

Easy ordering process, quality products, and dedicated support for your business success.

Product Description

Discover our high-purity PTFE (Polytetrafluoroethylene, commonly known as Teflon) Sampling Spoons, meticulously engineered for the safe, precise, and contamination-free handling of chemicals, solvents, powders, and various samples. The clean, white appearance is characteristic of high-quality virgin PTFE.

Key Features and Material Excellence

Our sampling spoons are crafted from 100% virgin PTFE, leveraging its exceptional material properties:

-

Unmatched Chemical Resistance: Inert to nearly all chemicals, acids, bases, and solvents, ensuring no corrosion or reaction with your samples.

-

High Thermal Stability: Suitable for use across a wide temperature range, maintaining structural integrity in demanding conditions.

-

Non-Stick Surface: The inherently low-friction surface of PTFE prevents sample adhesion, ensuring complete transfer and easy cleaning, minimizing cross-contamination.

-

Inert and Non-Leaching: Guarantees sample purity, critical for sensitive analyses in laboratories and high-purity processes in industries like semiconductor manufacturing.

-

Durable Construction: Designed for longevity and repeated use even in harsh environments.

-

Long Handle Design: Provides safe distance when handling aggressive or hazardous substances, and allows for easy reach into deep containers or reactors.

Versatile Applications Across Industries

These PTFE sampling spoons are indispensable tools for a wide array of applications, including:

-

Laboratories: Ideal for chemical analysis, biological research, pharmaceutical development, and quality control, where sample integrity is paramount.

-

Chemical Processing: Safely scoop and transfer aggressive chemicals, catalysts, and intermediates.

-

Semiconductor Manufacturing: Meets high-purity requirements for handling specialized chemicals and materials.

-

Food & Beverage: Suitable for sampling ingredients and products where non-reactivity and cleanliness are essential (PTFE is often FDA compliant).

-

Pharmaceuticals: For handling active pharmaceutical ingredients (APIs) and excipients without risk of contamination.

-

Environmental Testing: Collecting samples from various sources for analysis.

Advantages and Value to Our Customers

Choosing our PTFE sampling spoons offers significant benefits:

-

Enhanced Safety: Protects personnel from direct contact with hazardous materials.

-

Assured Sample Integrity: Prevents contamination, ensuring accurate analytical results and product quality.

-

Operational Efficiency: Easy to clean and reuse, reducing downtime and consumable costs.

-

Long-Term Reliability: Durable material offers an extended service life, providing excellent return on investment.

-

Process Versatility: Suitable for a broad spectrum of substances and operating conditions.

Product Specifications

| Capacity (ml) | Overall Length (mm) |

| 10 | 200 |

| 30 | 300 |

| 50 | 300 |

| 100 | 350 |

| 250 | 400 |

| 500 | 450 |

| 1000 | 500 |

Other sizes and custom dimensions are available upon request.

Tailored to Your Needs Customization

We understand that standard off-the-shelf solutions may not always meet the unique demands of every application. KINTEK excels in providing custom manufacturing services. We can tailor these PTFE sampling spoons to your exact specifications, including variations in cup volume, handle length, or even specific design modifications to integrate with your existing processes. From single prototypes for R&D to large-volume production runs for industrial deployment, we are equipped to deliver precision-engineered PTFE components that perform.

Trusted by Industry Leaders

FAQ

What Are The Main Applications Of PTFE Labware?

What Are The Main Applications Of PTFE Parts?

What Are The Main Applications Of PTFE Brushes?

What Are The Key Features Of PTFE Labware?

What Are The Key Features Of PTFE?

What Are The Key Features Of PTFE Brushes?

What Makes PTFE Suitable For Labware?

How Do PTFE O-ring Seals Work?

What Is The Principle Behind PTFE Brushes?

What Are The Advantages Of Using PTFE Labware?

What Are The Advantages Of Using PTFE Parts?

What Are The Advantages Of Using PTFE Brushes?

What Types Of PTFE Labware Are Available?

Why Is PTFE Suitable For CNC Machining?

Are PTFE Brushes Safe For Food And Medical Applications?

What Types Of PTFE Parts Are Commonly Manufactured?

How Does The Chemical Resistance Of PTFE Brushes Benefit Industrial Applications?

What Makes PTFE Brushes Suitable For High-temperature Environments?

Why Are PTFE Brushes Preferred For Electrical Insulation?

4.9 / 5

This spoon is a game-changer for lab work! Super durable and handles solvents like a champ.

4.8 / 5

Fast delivery and top-notch quality. Worth every penny for precision sampling.

4.7 / 5

Love how this spoon resists chemicals effortlessly. A must-have for any lab!

4.9 / 5

Incredibly reliable and sturdy. Perfect for high-precision solvent handling.

4.8 / 5

The PTFE material is flawless. No contamination issues at all. Highly recommend!

4.7 / 5

Great value for money. Works perfectly with aggressive solvents. Very impressed!

4.9 / 5

Tech advancement at its best. This spoon makes sampling so much easier and safer.

4.8 / 5

Durable and precise. Exactly what I needed for my chemical experiments.

4.7 / 5

Super fast shipping and the quality is outstanding. A lab essential!

4.9 / 5

The perfect tool for solvent sampling. No reactions, no fuss. Just perfection.

REQUEST A QUOTE

Our professional team will reply to you within one business day. Please feel free to contact us!

Related Products

Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

KINTEK prioritizes precision production and offers custom fabrication from prototypes to high-volume orders.

Custom PTFE Parts Manufacturer for Teflon Containers and Components

High-precision PTFE containers for labs & industry. Chemical-resistant, customizable sizes. Ideal for semiconductor, medical & lab applications. Get a quote!

Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

Discover the superior performance of our Polytetrafluoroethylene (PTFE) measuring cylinders, engineered for precision and resilience in demanding environments.

Custom PTFE Bottles for Diverse Industrial Applications

High-purity PTFE bottles for chemical storage, resistant to acids & solvents. Wide/narrow mouth options, leak-proof, durable. Ideal for labs & industry.

PTFE Deep Evaporating Dishes Customizable Laboratory and Industrial Solutions

High-quality PTFE deep evaporating dishes for labs. Chemical-resistant, non-stick, and customizable. Ideal for sample handling. Get yours now!

Customizable PTFE Crucibles for Laboratory and Industrial Applications

High-purity PTFE crucibles with lids for labs. Chemical-resistant, non-stick, and durable. Ideal for sample digestion, AA, ICP-MS. Custom sizes available.

Custom PTFE Shallow Evaporating Dishes for Diverse Applications

High-purity PTFE shallow evaporating dish for labs. Chemical-resistant, non-stick, ideal for sample evaporation. Custom sizes available. Order now!

Custom PTFE Teflon Parts Manufacturer PTFE Magnetic Stirring Bar

KINTEK PTFE magnetic stirring bars offer chemical resistance, high-temperature stability, and smooth mixing for labs. Ideal for diverse applications.

Custom PTFE Teflon Balls for Advanced Industrial Applications

Precision PTFE balls for chemical, medical & industrial use. High-performance, low-friction, chemical-resistant. Custom sizes available. Get a quote today!

Custom PTFE Square Trays for Industrial and Laboratory Use

Premium PTFE square trays for labs & industry. Chemical-resistant, non-stick, high-purity PTFE trays for semiconductors & medical use. Custom sizes available.

Custom PTFE Volumetric Flasks for Advanced Scientific and Industrial Use

Premium PTFE volumetric flasks for labs – chemical-resistant, non-stick, precise measurements. Ideal for semiconductor, medical & analytical applications. Shop now!

Customizable PTFE Scrapers and Shovels for Demanding Applications

High-purity PTFE scrapers & shovels for labs, semiconductor & chemical industries. Chemical-resistant, non-stick, durable tools for precise material handling. Custom solutions available.

Custom PTFE Sleeves and Hollow Rods for Advanced Applications

High-performance PTFE hollow rods & sleeves for chemical resistance, thermal stability, and low friction. Custom sizes available. Contact KINTEK today!

Customizable PTFE Three Neck Flasks for Advanced Chemical Applications

Our high-performance Three-Neck Round-Bottom Flasks are expertly crafted from pure Polytetrafluoroethylene (PTFE), a material renowned for its exceptional properties, making it ideal for demanding laboratory and industrial environments.

Customizable PTFE Seals Filter Holders for Versatile Applications

Enhance filtration with KINTEK's PTFE-sealed filter holders for leak-proof, chemical-resistant performance in labs and industries. Explore now!

Customizable PTFE Rods for Advanced Industrial Applications

High-performance PTFE solid rods for chemical-resistant, low-friction components. Ideal for lab, medical & industrial applications. Custom machining available.

Custom PTFE Evaporating Dishes for Diverse Applications

High-purity PTFE evaporating dishes for labs, resistant to acids & solvents. Non-stick, durable, ideal for sample prep. Custom sizes available. Order now!

Custom PTFE Microwave Digestion Vessels for Demanding Applications

High-purity PTFE microwave digestion vessels for safe, contamination-free sample prep. Ideal for ICP-MS, AAS, and trace analysis. Custom sizes available.

Custom PTFE Sealing Tapes for Industrial and High Tech Applications

KINTEK's PTFE sealing tape offers superior leak protection, chemical resistance, and high-temperature performance for industrial applications. Custom sizes available.

Related Articles

The Price of Purity: When a Simple Bottle Becomes Mission-Critical

Discover why PTFE bottles are not just containers, but precision tools that mitigate invisible risks in high-stakes chemical and sample handling.

The Fluorine Fortress: How PTFE's Molecular Simplicity Creates Unrivaled Performance

Discover how PTFE's simple carbon-fluorine bond creates a molecular fortress, leading to extreme chemical inertness and low friction.

Beyond 'Non-Stick': The Physics and Psychology of Purity in PTFE Labware

Discover how PTFE's intrinsic molecular properties, not just its surface, prevent sample loss and contamination, ensuring data integrity in critical science.

The Geometry of Silence: Mastering the Paradox of PTFE

PTFE offers unmatched inertness and low friction, yet poses unique fabrication challenges. Explore the engineering trade-offs of this material of extremes.

Beyond Sanitization: Why Your Material Choice Is the Real Key to Preventing Contamination

Recurring contamination in food & pharma isn't a process failure, but a material failure. Discover why PTFE is the key to lasting hygiene and uptime.

The Art of Material Selection: A Pragmatic Guide to PTFE's Strengths and Weaknesses

Effective PTFE application requires a deep understanding of its trade-offs. This guide explores its unique properties and critical limitations.

The Hidden Risk of PTFE: Why Your Go-To Material Is Now a Liability—And What to Do About It

Discover the hidden regulatory and performance risks of standard PTFE components. Learn why a strategic material choice is crucial for future-proofing your products.

The Economics of Inertia: Why PTFE is the Silent Guardian of Pharmaceutical Purity

Discover how PTFE components transform pharmaceutical economics by eliminating adhesion and ensuring purity. A deep dive into yield, TCO, and material science.

The Unbreakable Bond: Why PTFE Defines Chemical Containment and Purity

Explore the molecular basis of PTFE's near-absolute chemical resistance and its critical role in high-purity industrial applications.

The PTFE Trap: Why Your Team Is Debating the Wrong Question About "Forever Chemicals"

Confused by the PTFE vs. PTFE-free debate? Learn why the real risk isn't the material itself but its lifecycle, and how to choose the right component.

Your "Inert" PTFE Component Might Be the Real Source of System Failure

Inconsistent results? Learn why standard PTFE components fail under stress and how precision-fabricated, application-specific grades are the key to reliability.

The Invisible Tax on Motion: Engineering Beyond Friction with PTFE

Friction is the silent killer of mechanical efficiency. Discover how PTFE re-engineers motion for longevity, reducing energy loss and maintenance burdens.