The Invisible Contaminant

Imagine a trace metal analysis lab. Months of work culminate in a single, final measurement. But an unknown variable lurks—a few stray molecules from a previous sample, clinging invisibly to the walls of a seemingly clean container. The entire result is compromised.

This isn't a failure of cleaning protocol. It's a failure of material physics.

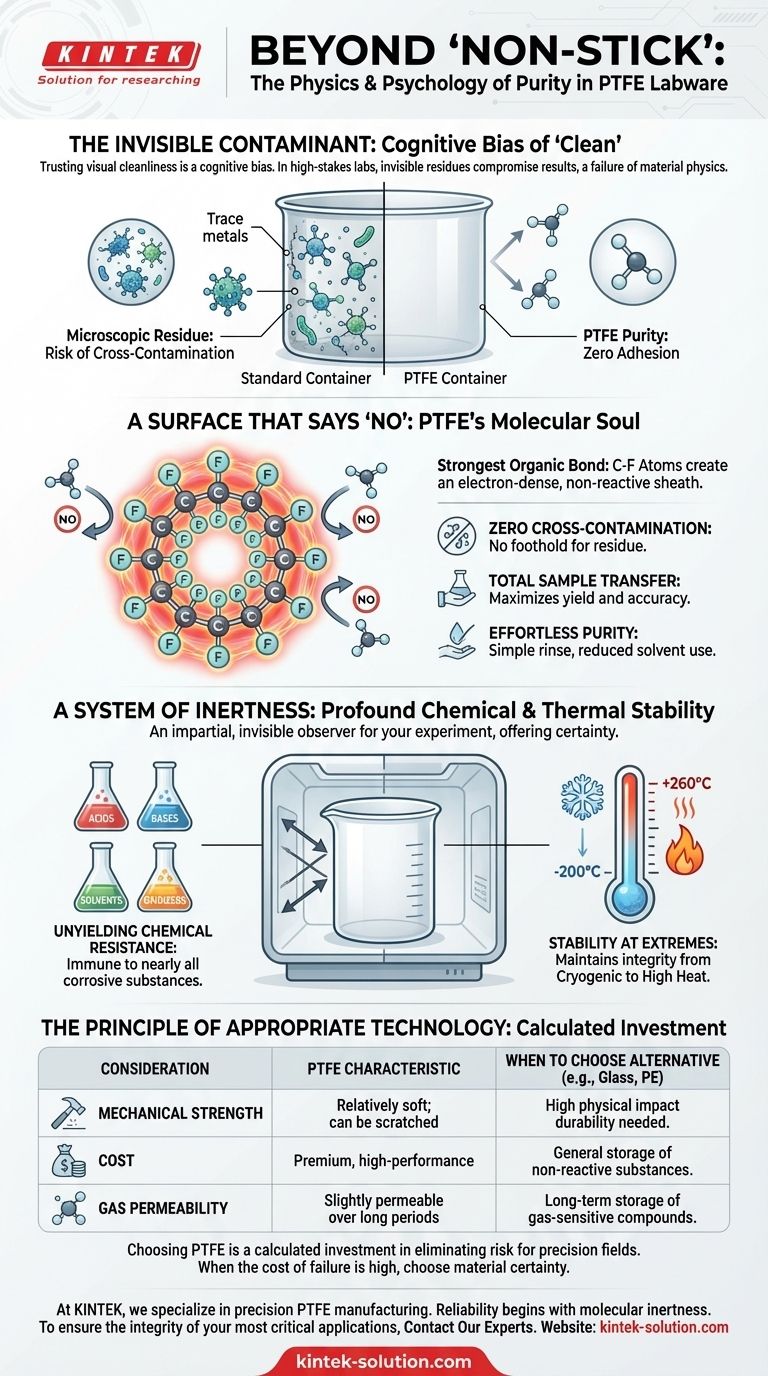

In high-stakes environments, from semiconductor fabrication to medical research, we develop a cognitive bias. We trust what we can see. If a vessel looks clean, we assume it is pure. Yet, at the microscopic level, most materials are battlegrounds of adhesion, where residues can mechanically and chemically bond to surfaces.

This is the quiet, persistent risk that high-performance labs are engineered to eliminate. The solution isn't better detergents; it's choosing a material that inherently refuses to participate in the battle.

A Surface That Says "No"

The non-stick property of Polytetrafluoroethylene (PTFE) is not a coating or a treatment. It is the physical manifestation of its molecular soul. The bond between carbon and fluorine atoms is one of the strongest in organic chemistry, creating an electron-dense sheath that is exceptionally stable and non-reactive.

This fundamental structure results in an incredibly low surface energy. Molecules that come into contact with PTFE find no foothold, no electrical charge to latch onto. They are left with little choice but to slide right off.

This isn't just about convenience. It’s about control. This molecular indifference delivers quantifiable advantages:

- Zero Cross-Contamination: Residue from a previous sample has nowhere to hide. This ensures the absolute purity of the next high-value reagent or analytical sample introduced.

- Total Sample Transfer: When every microliter counts in quantitative analysis, PTFE’s non-stick nature guarantees a complete transfer, maximizing yield and ensuring the accuracy of your measurements.

- Effortless Purity: Cleaning becomes a simple rinse rather than an aggressive chemical scrub. This saves time, reduces solvent consumption, and accelerates workflow.

A System of Inertness

The non-stick surface is merely the most famous symptom of PTFE's true character: profound chemical inertness. This material doesn’t just prevent physical adhesion; it resists chemical attack on a level that few other polymers can match.

Unyielding Chemical Resistance

PTFE is virtually immune to nearly all acids, bases, solvents, and oxidizing agents. This makes it the default choice for containing or transporting the most aggressive and corrosive substances, removing the variable of container degradation or leaching from your experiment.

Stability at the Extremes

From cryogenic applications at -200°C to high-heat processes reaching +260°C, PTFE maintains its structural integrity and its non-reactive properties. It provides a stable, trustworthy environment when the process itself is volatile.

This combination of properties creates a container that is less a participant in an experiment and more an impartial, invisible observer. It offers a degree of certainty in an environment defined by questions.

The Principle of Appropriate Technology

Of course, PTFE is not a universal solution. Its strengths are specific, and acknowledging its trade-offs is crucial for making an informed engineering decision.

| Consideration | PTFE Characteristic | When to Choose an Alternative (e.g., Glass, PE) |

|---|---|---|

| Mechanical Strength | Relatively soft; can be scratched by abrasives. | When durability against physical impact is key. |

| Cost | A premium, high-performance material. | For general storage of non-reactive substances. |

| Gas Permeability | Slightly permeable to certain gases over long periods. | For long-term storage of gas-sensitive compounds. |

Choosing PTFE is not about a blind preference for the "best" material. It is a calculated investment in eliminating risk. You choose it when the cost of a compromised sample or a failed process is orders of magnitude higher than the cost of the container itself.

In fields where precision is paramount, the choice of material is a statement of intent. It reflects an understanding that true control comes from mastering the variables you can—starting with the vessel that holds your work. For the most demanding applications in the semiconductor, medical, and industrial sectors, ensuring that control requires a partner who understands the physics of purity.

At KINTEK, we specialize in the precision manufacturing of PTFE components, from custom labware to critical industrial seals, because we know that reliability at the macro level begins with inertness at the molecular level. If your work demands absolute certainty, you need a material that makes no compromises.

To ensure the integrity of your most critical applications, Contact Our Experts.

Visual Guide

Related Products

- Custom PTFE Bottles for Diverse Industrial Applications

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

- Custom PTFE Teflon Balls for Advanced Industrial Applications

Related Articles

- The Real Reason You're Losing Samples: Why Your Choice of Lab Bottle Matters More Than You Think

- The Datasheet Said It Was Perfect. So Why Did Your Component Fail?

- The 260°C Illusion: Why Your PTFE Bottle's True Limit is a System, Not a Number

- The Invisible Threat: Why Material Inertness Defines Success in Ultra-Pure Systems

- The Hidden Cost of Chemical Containers: Why Yours Are Failing and How to Fix It