You’ve done your homework. You’ve cross-referenced the chemical compatibility charts. The datasheet for the new polymer seal you specified promises excellent resistance to the aggressive solvent in your new production line. The project gets the green light.

Then, just weeks into operation, the calls begin. There are micro-leaks. The process fluid shows trace contamination. You’re facing unexpected downtime and a team of frustrated engineers asking what went wrong. The component—the one that looked perfect on paper—has failed. And now, you’re back to square one, trying to understand why.

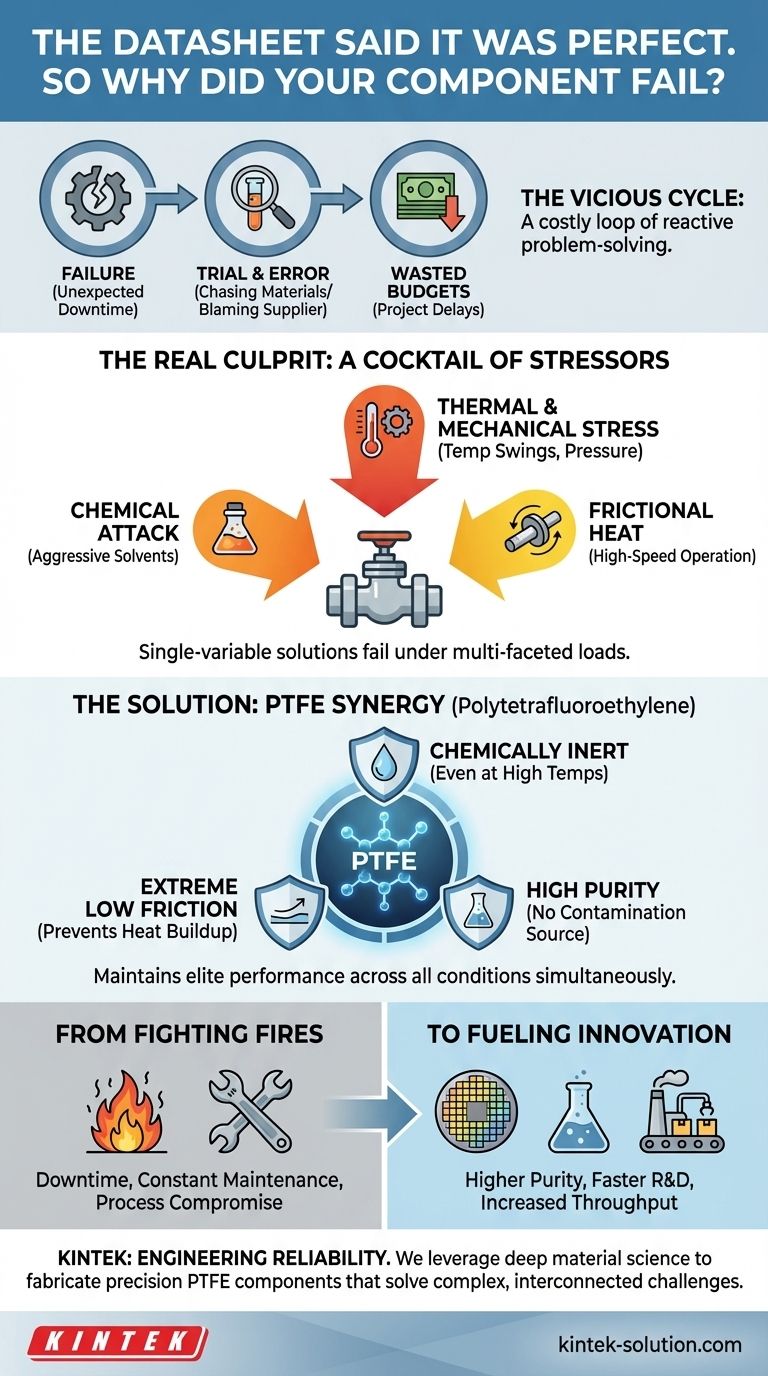

The Vicious Cycle of Trial, Error, and Wasted Budgets

If this scenario feels familiar, you’re not alone. In industries from semiconductor manufacturing to medical device R&D, engineers frequently encounter this frustrating paradox: a component that meets a single, critical specification fails spectacularly in a real-world application.

This kicks off a costly and time-consuming cycle. The common reactions are predictable:

- Chasing a "Stronger" Material: The first instinct is often to find a material that’s even more resistant to that one problem-causing factor, like a specific chemical. But this new material might be too brittle, too soft, or unable to handle the process temperatures, leading to a different kind of failure.

- Blaming the Supplier: It's easy to suspect a "bad batch" or a quality control issue. While possible, this often distracts from a more fundamental problem in material selection.

- Compromising the Process: To protect the failing component, teams might lower the operating temperature, reduce the pressure, or slow down line speeds. This "fix" cripples efficiency and throttles the very innovation the new process was meant to enable.

These reactions all stem from the same flawed approach. The business consequences are severe: project timelines are derailed, R&D budgets are consumed by re-testing and re-qualification, and the final product’s reliability is compromised before it even launches.

The Real Culprit: Why Your Application is a Cocktail of Stress

The component didn’t fail because the datasheet lied. It failed because datasheets often encourage a one-dimensional mindset. The true operating environment of your application is rarely a single, isolated challenge. It’s a cocktail of stressors.

Think about it:

- A valve seat isn't just sitting in an aggressive chemical; it's also enduring the mechanical stress of opening and closing.

- A seal in a pump isn't just providing chemical resistance; it's also handling the frictional heat from a high-speed rotating shaft.

- A wafer carrier in a semiconductor fab isn't just holding a wafer; it must maintain its purity and structural integrity across extreme temperature swings.

Most engineering materials are specialists. They might offer world-class chemical resistance but soften dramatically under heat. Or they might have incredible thermal stability but generate excessive friction in a dynamic application.

This is the root of the problem: You chose a material to solve for variable A (e.g., chemical attack), but it was the combination of A, B (heat), and C (pressure) that caused the failure. The common "solutions" fail because they are still trying to solve for a single variable, playing a frustrating game of whack-a-mole with material properties.

The Solution: A Material Built for a Multi-Faceted World

To break this cycle, you don't need a material that's simply "better" at one thing. You need a material that maintains its elite performance across a range of conditions simultaneously. You need a material that can handle the entire cocktail of stress.

This is precisely where PTFE (Polytetrafluoroethylene) distinguishes itself. Its value isn't just one standout feature, but the powerful synergy of its core properties:

- It remains chemically inert even at high temperatures.

- Its extreme low friction prevents the buildup of frictional heat that could compromise its thermal and mechanical integrity.

- Its high purity is maintained across a wide operating temperature range, ensuring it doesn't become a source of contamination.

PTFE wasn’t designed to be a one-trick pony. It was designed for the complex, multi-faceted reality of high-performance applications.

KINTEK: Engineering Reliability from a Deeper Understanding

This is the principle our work is built on. At KINTEK, we don't just sell PTFE components; we engineer solutions based on a deep understanding of these material science fundamentals. We manufacture precision PTFE seals, liners, and custom labware because we know they are the answer to these complex, interconnected challenges.

Our expertise in precision fabrication ensures that the unique properties of PTFE are translated into components that perform flawlessly. A KINTEK seal prevents leaks not just because PTFE is inert, but because our manufacturing precision combined with the material’s low friction and thermal stability ensures it maintains a perfect fit, even under dynamic and thermal loads.

From Fighting Fires to Fueling Innovation

Once you solve this recurring problem of component failure, the focus shifts. Instead of spending your time and budget on diagnosing yesterday's problems, you can start engineering tomorrow's breakthroughs.

When you can trust your components to withstand the entire cocktail of stressors, new possibilities emerge:

- Semiconductor fabs can push to higher-purity processes and more aggressive cleaning cycles, confident that their components won't degrade and contaminate a multi-million dollar wafer batch.

- Medical and lab teams can accelerate R&D by running more demanding analytical tests and sterilization protocols without fear of equipment failure.

- Industrial plants can operate production lines at higher speeds and temperatures, dramatically increasing throughput without scheduling constant maintenance shutdowns.

Ultimately, solving this fundamental material challenge isn’t just about fixing a leak. It’s about creating the operational confidence needed to innovate faster, build more reliable products, and outperform the competition.

Your challenges are unique, involving a complex mix of chemical, thermal, and mechanical stresses. If you're tired of the cycle of trial and error and ready to build for reliability from the ground up, our team is here to help you apply these principles to your specific project. Contact Our Experts.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Square Trays for Industrial and Laboratory Use

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

Related Articles

- The Unseen Workhorse: Why PTFE Is the Default Choice for Impossible Problems

- How PTFE Solves Critical Industrial Challenges Through Material Superiority

- Your "Inert" PTFE Component Might Be the Real Source of System Failure

- The Physics of a Perfect Fit: How PTFE Eliminates an Athlete's Hidden Distractions

- When "Chemically Inert" Isn't Enough: The Hidden Cause of PTFE Component Failure