The Silence of a Perfect Component

In a semiconductor fab, a chemical processing plant, or a medical device assembly, failure is measured in catastrophic terms. A single contaminated batch or a seized pump can halt a multi-million dollar operation. The culprit is often a component so small it’s overlooked: a seal, a bearing, a liner.

Engineers are trained to solve problems by adding things—stronger alloys, better lubricants, more robust designs. But a certain class of problems can only be solved by taking things away. By choosing a material that strategically does nothing.

This is the quiet genius of Polytetrafluoroethylene (PTFE). It is not just a replacement for metal; it represents a different philosophy of engineering.

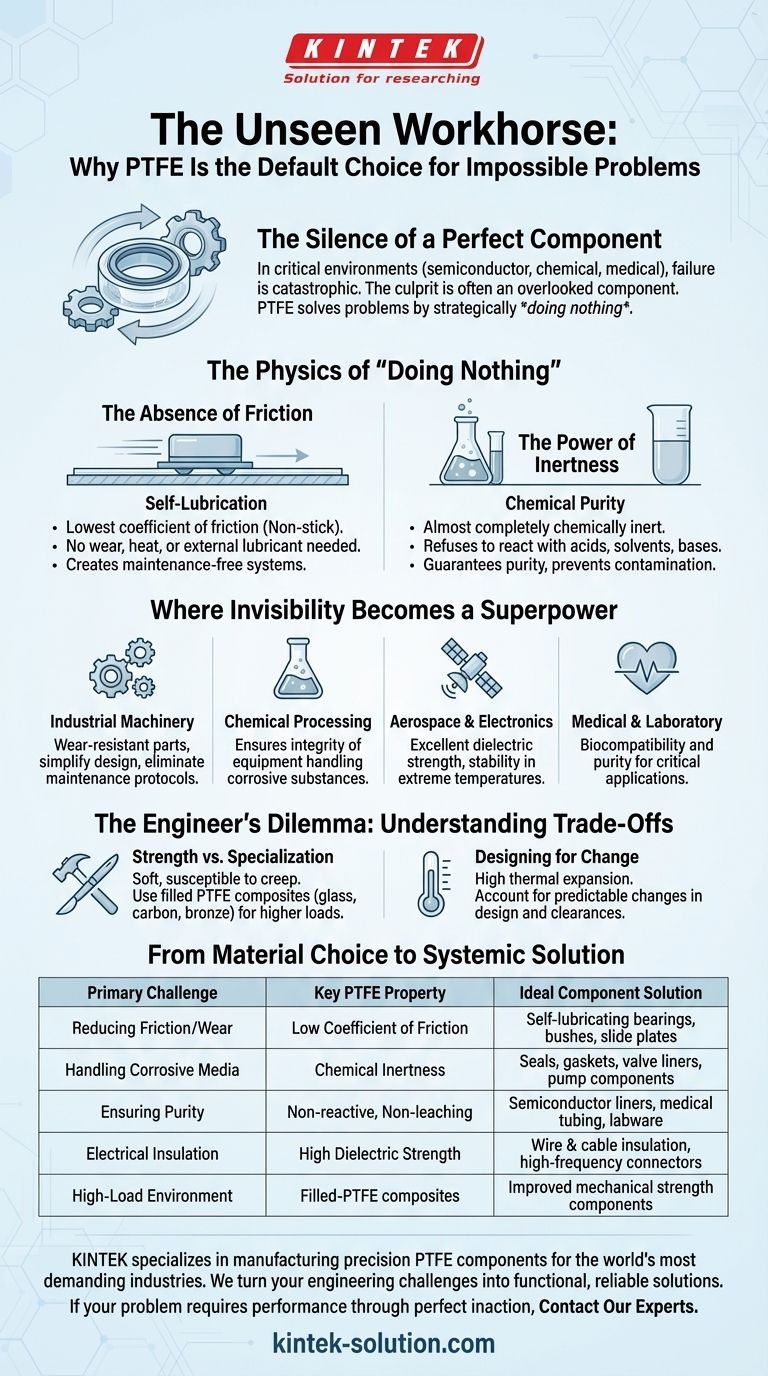

The Physics of "Doing Nothing"

PTFE's power comes not from what it does, but from what it doesn't do. Its molecular structure gives it two seemingly passive, yet incredibly potent, characteristics.

The Absence of Friction

PTFE has one of the lowest coefficients of friction of any solid. We call this "non-stick," but its true engineering value is "self-lubrication."

In a mechanical assembly, this means parts can move against each other almost endlessly without wear, heat generation, or the need for external lubricants. This isn't just about convenience. It’s about designing a system that eliminates a failure point entirely. Imagine a bearing in a satellite or a sealed pump handling corrosive chemicals—places where applying grease is not an option. The PTFE bush doesn't need it. It creates a maintenance-free system by design.

The Power of Inertness

PTFE is almost completely chemically inert. It refuses to react with the most aggressive acids, solvents, and bases.

This is not just resistance; it is a guarantee of purity. In semiconductor manufacturing, a component that leaches even a few ions can ruin a batch of wafers. In a medical implant, reactivity can be fatal. PTFE liners, seals, and labware provide a perfectly neutral boundary, ensuring the process or patient is only exposed to what is intended. It endures the chaos without participating in it.

Where Invisibility Becomes a Superpower

This unique combination of properties makes PTFE the unseen workhorse in environments where failure is not an option.

- Industrial Machinery: In bearings, gears, and slide plates, PTFE's self-lubricating nature creates wear-resistant parts that simplify design and eliminate entire maintenance protocols.

- Chemical Processing: For seals, gaskets, and linings in pumps and valves, its inertness ensures the integrity of equipment handling substances that would dissolve metal.

- Aerospace & Electronics: Excellent dielectric strength and stability across extreme temperatures make it the default choice for critical wire insulation and connectors, ensuring signal integrity from cryogenic lows to high-heat environments.

- Medical & Laboratory: Biocompatibility and purity make it essential for medical devices, surgical components, and laboratory containers where preventing contamination is the primary goal.

The Engineer's Dilemma: Understanding Trade-Offs

No material is a universal solution. An honest assessment means acknowledging PTFE's limitations not as flaws, but as design parameters.

Strength vs. Specialization

Compared to metals, PTFE is soft and can be susceptible to "creep" (slow deformation under load). You wouldn't build a load-bearing frame from it. But this is like criticizing a scalpel for being a poor hammer. PTFE is a specialist. For applications requiring higher compressive strength, its properties can be enhanced by creating filled PTFE composites, blending it with materials like glass, carbon, or bronze to create a material tailored to the load.

Designing for Change

PTFE expands and contracts with temperature more than metal. A novice might see this as a problem. An experienced engineer sees it as a predictable variable to be accounted for in the design, ensuring proper clearances are calculated so that parts never bind or loosen.

From Material Choice to Systemic Solution

The decision is rarely about whether PTFE is the right material, but rather which form of PTFE is best suited for the job and if it can be manufactured to the required precision. The challenges define the solution.

| Primary Challenge | Key PTFE Property | Ideal Component Solution |

|---|---|---|

| Reducing Friction/Wear | Low Coefficient of Friction | Self-lubricating bearings, bushes, slide plates |

| Handling Corrosive Media | Chemical Inertness | Seals, gaskets, valve liners, pump components |

| Ensuring Purity | Non-reactive, Non-leaching | Semiconductor liners, medical tubing, labware |

| Electrical Insulation | High Dielectric Strength | Wire & cable insulation, high-frequency connectors |

| High-Load Environment | (Enhanced Property) | Filled-PTFE composites for improved mechanical strength |

Choosing the right material is only the first step. Translating that choice into a reliable, precision-manufactured component is where theory meets reality. A seal for a semiconductor wet bench requires different tolerances than a bush for an industrial conveyor. This is where expertise in fabrication becomes as critical as the material itself.

At KINTEK, we specialize in manufacturing precision PTFE components for the world's most demanding industries. From custom-machined seals and liners for semiconductor and medical applications to high-performance bushes for industrial machinery, we turn your engineering challenges into functional, reliable solutions.

If your problem requires a component that delivers performance through perfect inaction, Contact Our Experts

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Customizable PTFE Rods for Advanced Industrial Applications

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Square Trays for Industrial and Laboratory Use

Related Articles

- How PTFE Solves Critical Industrial Challenges Through Material Superiority

- The PTFE Paradox: Why the 'Perfect' Material Fails—And How to Make It Work

- The Unseen Guardian: How PTFE's Molecular Shield Protects Our Most Critical Systems

- The Physics of Trust: Why PTFE Is the Bedrock of High-Stakes Electronics

- When "Chemically Inert" Isn't Enough: The Hidden Cause of PTFE Component Failure