It’s a frustratingly common scene for engineers and lab managers in high-stakes industries. A critical production line grinds to a halt. A crucial experiment is contaminated. The cause? A single component—a seal, a liner, a valve seat—has failed.

You chose the material specifically for its "superior" properties. It was supposed to be chemically inert, temperature-resistant, and ultra-reliable. Yet here you are, facing costly downtime, wasted materials, and another missed deadline, all because the “perfect” material didn’t perform as promised.

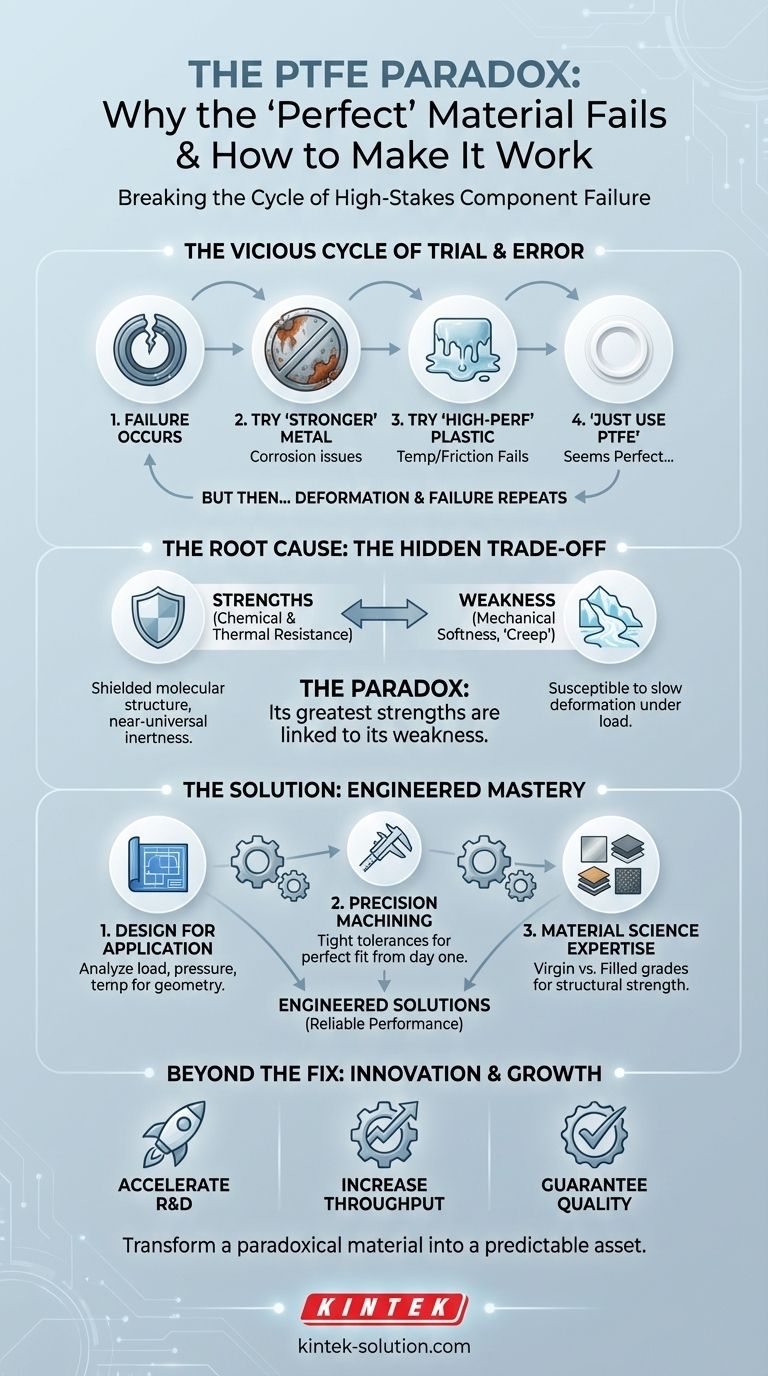

The Vicious Cycle of Trial and Error

If this story feels familiar, you're not alone. When a component fails in a demanding environment (like inside a chemical reactor or a semiconductor wet bench), the troubleshooting process often looks like this:

- Try a "Stronger" Metal Alloy: You switch from 316L stainless steel to a more exotic alloy like Hastelloy. It works for a while, but eventually, corrosion finds a way, and the cost skyrockets.

- Try a Different "High-Performance" Plastic: You experiment with PEEK or another polymer. It might solve the chemical issue but fails at higher temperatures or doesn't provide the necessary low-friction surface.

- "Just Use PTFE": Finally, you turn to Polytetrafluoroethylene (PTFE), the legendary material known for its near-universal chemical inertness and extreme temperature stability. It seems like the final answer.

But then, a few weeks or months later, it fails too. Not by corroding or melting, but by deforming. The seal loses its shape, the liner bulges, and the failure cycle begins again. Each loop of this cycle burns more budget, delays projects, and, most importantly, erodes confidence in your product's or process's reliability.

The Root Cause: The Hidden Trade-Off Inside PTFE

The reason this cycle is so hard to break is that most people misdiagnose the problem. The failure isn't in the material you chose; it's in a fundamental misunderstanding of its nature.

PTFE is a material of extremes. The same unique molecular structure (a long chain of carbon atoms completely shielded by fluorine atoms) that gives it almost supernatural chemical and thermal resistance also makes it mechanically soft. Compared to metals or even other engineering plastics, PTFE is susceptible to "creep"—a slow, gradual deformation when placed under a constant load or pressure.

Think of it like a glacier: its movement is imperceptible moment to moment, but over time, it reshapes the landscape. Similarly, a PTFE component under mechanical stress will slowly "flow" out of its specified dimensions, eventually causing a leak or mechanical failure.

This is the PTFE paradox: its greatest strengths are inextricably linked to its greatest weakness.

The common "solutions" fail because they only address one side of the equation:

- Switching to a different metal solves the mechanical strength issue but re-introduces the chemical corrosion problem.

- Making a standard PTFE part thicker doesn't stop creep; it just uses more material that will eventually deform anyway.

You were trying to solve a chemical or thermal problem, but you unknowingly created a mechanical one.

The Solution: It’s Not Just the Material, It’s the Mastery

To break the cycle, you need to stop thinking about a simple material swap and start thinking about holistic component design. The solution isn't just to use PTFE; it's to use PTFE correctly.

This requires a deep understanding of how to counteract its inherent tendency to creep while preserving its elite performance characteristics. To do this, you need a partner who sees PTFE not as a raw material to be sold, but as a complex medium to be mastered.

This is where expert fabrication becomes critical. A true solution involves:

- Design for the Application: Analyzing the specific load, pressure, and temperature your component will face to design a part geometry that minimizes stress points and mitigates creep.

- Precision Machining: Holding exceptionally tight tolerances to ensure a perfect fit from day one, because any initial gap can accelerate the process of deformation.

- Material Science Expertise: Knowing when to use virgin PTFE versus a filled grade (e.g., glass- or carbon-filled) to enhance mechanical strength for structural applications without compromising its core benefits.

At KINTEK, we don't just sell PTFE parts. We deliver engineered solutions. Our entire process is built on a deep understanding of the PTFE paradox. We manufacture precision components—from custom labware and liners to high-purity seals—that are specifically designed to perform reliably in the most demanding semiconductor, medical, and industrial environments. We treat PTFE's "difficult to process" nature not as a limitation, but as our core value proposition.

Beyond the Fix: From Constant Firefighting to Breakthrough Innovation

When you finally solve this recurring component failure, something remarkable happens. You're no longer just patching a problem; you're building a more robust, reliable foundation for your entire operation.

The resources once spent on troubleshooting, downtime, and replacement parts are freed up. Instead of worrying about material compatibility, you can:

- Accelerate R&D: Push your processes to higher temperatures or use more aggressive chemicals to innovate faster.

- Increase Throughput: Run your production lines for longer, with greater confidence and less maintenance.

- Guarantee Quality: Ensure the purity and integrity of your end-product, whether it's a life-saving medical device or a next-generation semiconductor chip.

The failure of a single seal isn't just a technical issue; it's a business bottleneck that limits your potential. By partnering with an expert who understands how to transform a paradoxical material into a predictable asset, you can remove that bottleneck for good. Let's move beyond stop-gap solutions and build a more resilient foundation for your most critical applications. Contact Our Experts to discuss how precision-fabricated PTFE components can strengthen your entire operation.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Square Trays for Industrial and Laboratory Use

Related Articles

- Your "Inert" PTFE Component Might Be the Real Source of System Failure

- The Physics of Trust: Why PTFE Is the Bedrock of High-Stakes Electronics

- When "Chemically Inert" Isn't Enough: The Hidden Cause of PTFE Component Failure

- Beyond "Non-Stick": Why Your PTFE Components Fail and How to Fix It for Good

- Why Your High-Performance PTFE Parts Fail—And Why It's Not the Material's Fault