A Matter of Trust, Not Just Tolerance

An engineer designing a satellite communications array isn't just choosing a material. They are placing a bet on its behavior. Miles above the Earth, exposed to cosmic radiation and temperature swings of hundreds of degrees, a single component failure can doom a billion-dollar mission.

This isn't a problem of simple insulation. It's a problem of trust.

In high-stakes engineering, trust isn't an emotion; it's the predictable, unwavering performance of a material under extreme stress. While many plastics can block an electric current, few earn the trust required for mission-critical systems. Polytetrafluoroethylene (PTFE) is one of those few. Its value comes not from a single property, but from its profound stability across electrical, thermal, and chemical extremes.

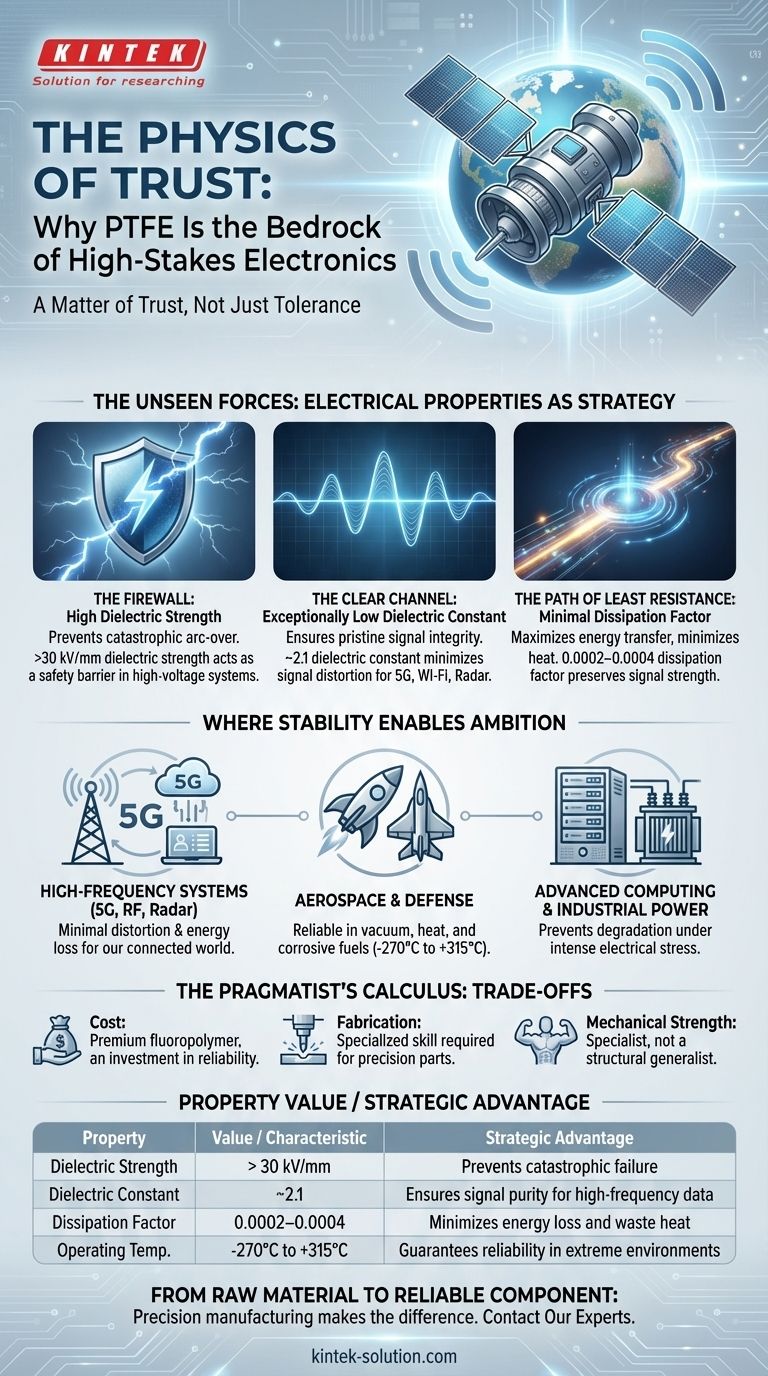

The Unseen Forces: Electrical Properties as Strategy

To understand why engineers bet on PTFE, we must look beyond the surface to the fundamental physics that govern its behavior. These properties are not just numbers on a datasheet; they are strategic advantages.

The Firewall: High Dielectric Strength

Dielectric strength is a material's breaking point under electrical pressure. PTFE’s strength, often exceeding 30 kV/mm, acts as an impenetrable firewall.

Think of it as the difference between a flimsy fence and a reinforced concrete wall. In high-voltage applications, from advanced transformers to medical devices, this property isn't just about efficiency—it's about preventing catastrophic arc-over and ensuring the safety and longevity of the entire system.

The Clear Channel: An Exceptionally Low Dielectric Constant

In the world of high-frequency data—the backbone of 5G, Wi-Fi, and radar—the insulating material can become an obstacle. Most insulators store a small amount of electrical energy, which can distort or "smear" a fast-traveling signal.

PTFE has a remarkably low dielectric constant of around 2.1. This means it barely interacts with the electrical field passing through it. The signal flows through, clean and uncorrupted, as if the insulator isn't even there. This property is what allows for the pristine signal integrity required to transmit vast amounts of data in a fraction of a second.

The Path of Least Resistance: Minimal Dissipation Factor

Every time a signal passes through a material, a tiny fraction of its energy is lost as heat. This is measured by the dissipation factor. For PTFE, that number is almost zero (0.0002–0.0004).

This near-perfect energy transfer is critical for two reasons. First, it preserves the strength and clarity of the signal. Second, it prevents waste heat buildup—a mortal enemy in densely packed electronics like server farms or phased-array antennas. PTFE ensures the energy goes into the signal, not into warming the hardware.

Where Stability Enables Ambition

These core properties converge to solve some of the most difficult challenges in modern technology.

- High-Frequency Systems (5G, RF, Radar): In these applications, speed and clarity are everything. PTFE is the default choice for high-performance coaxial cables and PCBs because it allows signals to travel with minimal distortion or energy loss, making our connected world possible.

- Aerospace and Defense: Components must survive the vacuum of space, the heat of re-entry, and corrosive jet fuel. PTFE remains indifferent to these extremes. Its chemical inertness and vast operating temperature range (-270°C to +315°C) make it the ultimate reliable insulator for wiring harnesses and connector assemblies where failure is not an option.

- Advanced Computing & Industrial Power: In powerful transformers and high-density servers, intense heat and electrical stress are constant. PTFE insulation prevents components from degrading or arcing, ensuring the long-term operational reliability that underpins our data infrastructure.

The Pragmatist's Calculus: Acknowledging Trade-offs

Of course, no material is perfect for every scenario. The decision to use PTFE is a conscious one, weighing its supreme performance against practical constraints.

- Cost: PTFE is a premium fluoropolymer, more expensive than commodity insulators like PVC. Its use is an investment in reliability.

- Fabrication: As a soft and slippery material, machining PTFE to tight tolerances is a specialized skill. It requires expertise to transform raw stock into a precision component without compromising its integrity.

- Mechanical Strength: Compared to engineering plastics like PEEK, PTFE has lower tensile strength. It is a specialist, not a generalist, chosen for its electrical and chemical prowess, not its structural rigidity.

| Property | Value/Characteristic | Strategic Advantage |

|---|---|---|

| Dielectric Strength | > 30 kV/mm | Prevents catastrophic failure in high-voltage systems |

| Dielectric Constant | ~2.1 | Ensures signal purity for high-frequency data (5G, RF) |

| Dissipation Factor | 0.0002–0.0004 | Minimizes energy loss and waste heat |

| Operating Temp. | -270°C to +315°C | Guarantees reliability in extreme environments |

From Raw Material to Reliable Component

The theoretical advantages of PTFE are only realized when the material is expertly fabricated into a final component. A poorly machined seal or insulator can undo all the inherent benefits of the polymer itself.

This is where material science meets craftsmanship. KINTEK specializes in the precision manufacturing of PTFE components for the most demanding industries, from semiconductor and medical to aerospace and industrial processing. We understand that turning a remarkable material into a reliable part requires deep expertise, from prototyping unique designs to executing high-volume production runs.

For applications where electrical integrity and environmental stability are non-negotiable, the right material is only half the battle; precision manufacturing is the other. Contact Our Experts to ensure your components perform as intended.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Square Trays for Industrial and Laboratory Use

Related Articles

- Beyond "Non-Stick": Why Your PTFE Components Fail and How to Fix It for Good

- When "Chemically Inert" Isn't Enough: The Hidden Cause of PTFE Component Failure

- Why Your High-Performance PTFE Parts Fail—And Why It's Not the Material's Fault

- How PTFE Solves Critical Industrial Challenges Through Material Superiority

- Your "Inert" PTFE Component Might Be the Real Source of System Failure