It’s a scenario familiar to many engineers and lab managers. You’ve selected PTFE for its legendary chemical inertness and thermal stability—the perfect material on paper for your critical application. Yet, the custom seal leaks under pressure, the vessel liner shows signs of stress after a thermal cycle, or the precision component is just slightly out of tolerance, compromising an entire assembly. The part has failed, and with it, a costly batch of product is ruined, a research timeline is delayed, or a piece of capital equipment is down.

You’re left wondering: Was it the wrong grade of PTFE? Should the design be thicker? Was there a flaw in the raw material?

The High Cost of "Close Enough"

This uncertainty kicks off a frustrating and expensive cycle of trial and error. You might order a component from a different supplier, hoping for better luck. You might try reinforcing the design, adding complexity and cost. Or you might even start to question if PTFE was the right choice in the first place, sending your team back to the drawing board to research alternative, often more exotic and expensive, materials.

Each loop in this cycle carries a heavy business cost:

- Wasted Resources: Every failed component means lost material, wasted machine time, and scrapped end-products, whether that’s a batch of pharmaceuticals or a set of semiconductor wafers.

- Project Delays: Troubleshooting component failure pushes back timelines, delaying product launches and slowing down critical research.

- Compromised Reliability: When you can't trust your components, you can't guarantee the performance or safety of your final product, putting your reputation on the line.

The frustrating truth is that these conventional "fixes" rarely solve the problem for good. That's because they are all based on a false premise. The problem usually isn't the material; it’s the fabrication.

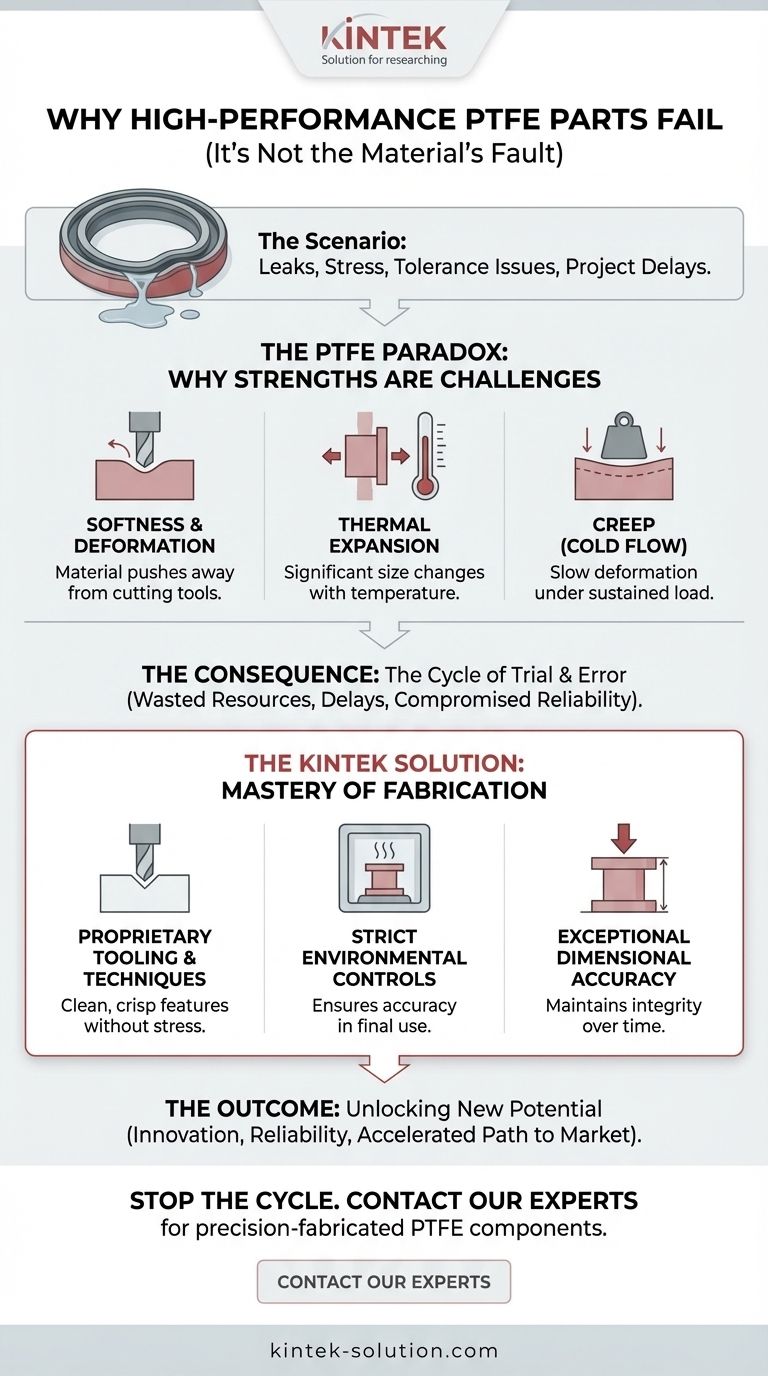

The PTFE Paradox: Why Its Strengths Are Its Biggest Challenge

PTFE is a material of extremes. The very properties that make it so valuable for demanding applications also make it notoriously difficult to shape into a precise and reliable component. This is the root of the problem that most suppliers fail to address.

The Challenge of Softness

Unlike rigid metals or plastics, PTFE is soft and has an extremely low coefficient of friction. When a cutting tool is applied, the material has a tendency to push away and deform rather than shear cleanly. Without specialized tooling and techniques, this results in burrs, imprecise edges, and an inability to hold tight tolerances—the microscopic flaws that later become leak paths and stress points.

The Challenge of Thermal Expansion

PTFE has a very high coefficient of thermal expansion. This means it expands and contracts significantly with even small temperature changes. The heat generated during the machining process itself can cause the material to change size, making it nearly impossible to achieve high precision without a deep understanding of thermal compensation and a tightly controlled environment. A part measured as "perfect" on a warm machine can be out of spec once it cools to room temperature.

The Challenge of Creep (Cold Flow)

Under sustained pressure, even at room temperature, PTFE has a tendency to "creep," or slowly deform over time. A seal that is perfectly dimensioned can fail weeks later because the material has subtly flowed out of its intended shape. This makes the initial precision of the component absolutely critical; there is no margin for error.

These common "solutions"—changing the grade or tweaking the design—are like trying to fix a faulty engine by repainting the car. They don't address the fundamental issue: the part was not fabricated with the necessary expertise to master PTFE's unique behavior.

From Raw Material to Reliable Part: The Mastery of Fabrication

To truly solve this problem, you need more than just PTFE. You need a component that is the product of a process specifically designed to overcome PTFE's inherent challenges. You need a partner who understands that fabricating PTFE is a science in itself.

This is where KINTEK’s expertise becomes your advantage. We don’t just sell PTFE parts; we provide precision-engineered solutions born from a deep understanding of the material's paradoxical nature.

- To counter softness and deformation, we utilize proprietary tooling, cutting speeds, and machining techniques that create clean, crisp features without stressing the material.

- To manage thermal expansion, our processes involve strict environmental controls and advanced compensation methods that ensure the final component is true to your specification, not just at the moment it’s cut, but when it’s installed in your equipment.

- To prevent failures from creep, we deliver exceptional dimensional accuracy and surface finishes from the start, ensuring our seals, liners, and components maintain their integrity under the specified load for the long haul.

Our components are not just "made from PTFE." They are engineered to deliver the full promise of PTFE's performance, without the frustrating failures.

Beyond Fixing Failures: Unlocking New Potential

When you stop worrying about component reliability, you can start pushing the boundaries of what’s possible. With precisely fabricated PTFE parts you can trust, your team is free to innovate.

You can design more complex chemical processes, knowing your liners and seals will provide total inertness. You can increase the operating temperatures of your equipment, confident that every component will maintain its structural integrity. You can develop more sensitive medical and laboratory devices, assured of the absolute purity and non-reactivity of every fluid path. This isn't just about preventing failures; it's about enabling breakthroughs and accelerating your path to market.

Stop the cycle of trial and error. Let's discuss how precision-fabricated PTFE components can solve your most persistent challenges and enhance the performance and reliability of your products. Contact Our Experts to discuss your specific application.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Customizable PTFE Rods for Advanced Industrial Applications

- Custom PTFE Square Trays for Industrial and Laboratory Use

- Custom PTFE Teflon Balls for Advanced Industrial Applications

Related Articles

- The Physics of Trust: Why PTFE Is the Bedrock of High-Stakes Electronics

- Your "Inert" PTFE Component Might Be the Real Source of System Failure

- When "Chemically Inert" Isn't Enough: The Hidden Cause of PTFE Component Failure

- The Unseen Guardian: How PTFE's Molecular Shield Protects Our Most Critical Systems

- How PTFE Solves Critical Industrial Challenges Through Material Superiority