You’ve done everything right. The process chemistry is perfect, the equipment is calibrated, and the team is following protocol to the letter. Yet, the results are inexplicably inconsistent. A multi-million dollar semiconductor run is plagued by trace contamination. A critical diagnostic test yields unreliable data. You spend weeks troubleshooting, searching for a ghost in the machine, only to suspect the one component you took for granted: a simple PTFE seal, liner, or tube.

It’s supposed to be one of the most stable, inert materials known to science. So why is it sabotaging your work?

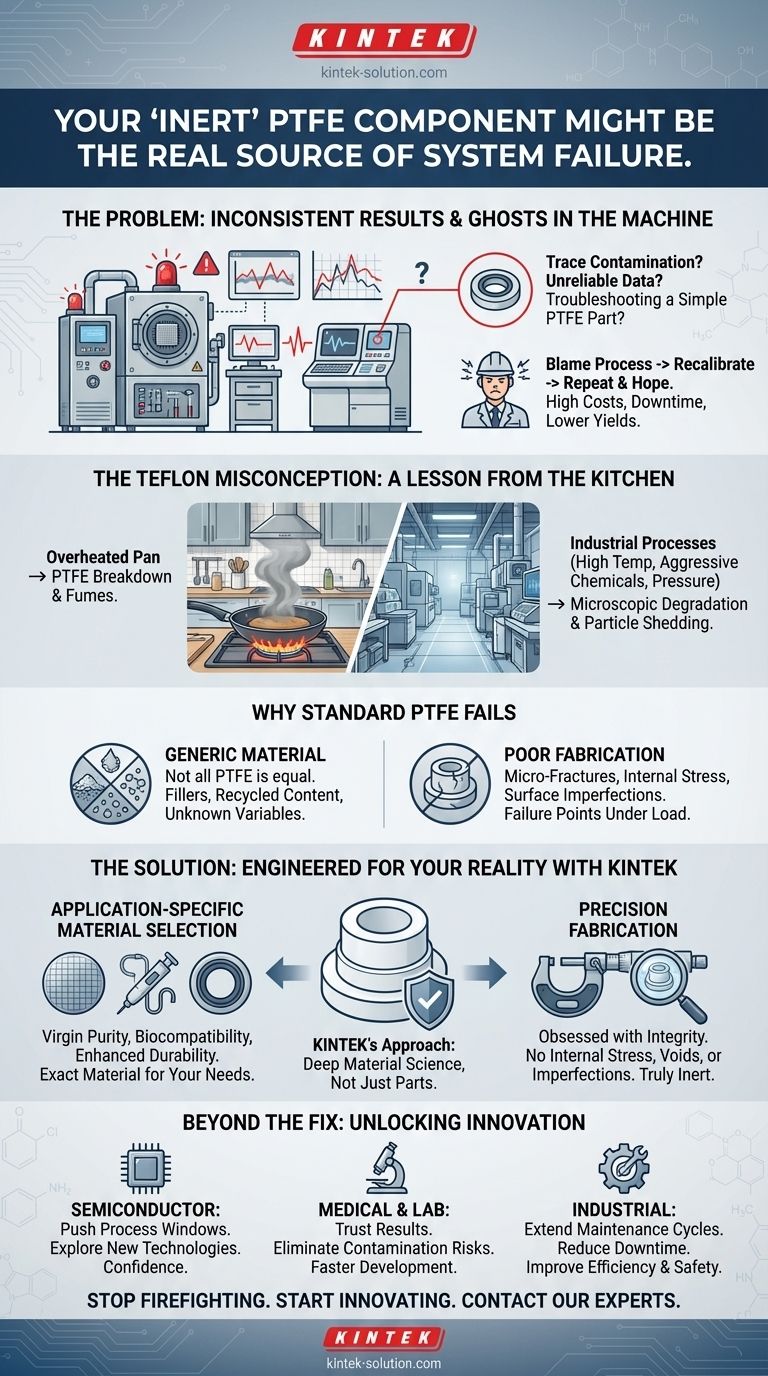

The Frustrating Cycle of "Solving" the Wrong Problem

If this scenario feels familiar, you're not alone. When high-purity or high-performance systems start to fail, engineers and lab managers often fall into a predictable and costly cycle:

- Blame the Process: They question the chemical reagents, the gas purity, or the sample integrity, spending a fortune on higher-grade consumables that don't fix the issue.

- Recalibrate Everything: They service and recalibrate expensive machinery, assuming a sensor has drifted or a controller is malfunctioning. This leads to downtime but no resolution.

- Repeat and Hope: They re-run the process, hoping the last failure was a one-off fluke, burning through time, budget, and team morale.

The commercial consequences are severe. For a semiconductor fab, it means lower yields and delayed shipments. For a medical device company, it means struggling to meet validation requirements for FDA approval. For a research lab, it means lost time and questionable data that undermines discovery.

These efforts fail for one simple reason: they are all focused on the symptoms, not the disease. The problem isn't your process; it's a fundamental misunderstanding of the material you're using.

The Teflon Misconception: A Lesson from the Kitchen

The root of the problem is hiding in plain sight—in a place you might not expect to find an industrial insight: your kitchen.

We all know you shouldn't overheat a non-stick (PTFE) frying pan. Why? Because at high temperatures—around 500°F (260°C)—the stable polymer begins to break down. It doesn’t melt; it degrades, releasing microscopic particles. In a kitchen, this means toxic fumes.

Now, apply that same principle to your highly demanding industrial environment. Your processes might involve not only high temperatures but also aggressive chemicals, high pressures, and extreme purity requirements.

Why Standard PTFE Fails

The "common solutions" you tried didn't work because the PTFE component you trusted was, in fact, silently breaking down. Under the stress of your specific application, it was undergoing microscopic thermal or chemical degradation. This is why:

- Not All PTFE is Created Equal: The generic PTFE used in low-demand applications is not the same as a specialized, virgin-grade material designed for semiconductor purity or biocompatibility. Fillers, recycled content, or improper processing in a "standard" component can introduce a host of unknown variables.

- Fabrication Is as Important as Material: A poorly fabricated component, even if made from good material, can contain micro-fractures, internal stresses, or surface imperfections. Under pressure or thermal cycling, these become microscopic failure points, shedding particles and leaching impurities directly into your system.

You weren't fighting a random process error. You were fighting a material science problem at its core. You were using a frying pan for a semiconductor reactor.

The Right Tool for the Job: Engineered for Your Reality

To permanently solve this problem, you don't just need PTFE; you need the right PTFE, fabricated with the right expertise. You need a component that is purpose-built to withstand the unique chemical, thermal, and mechanical stresses of your application without degrading.

This is precisely why KINTEK's approach is different. We don't just supply parts; we engineer solutions based on a deep understanding of material science. Our components are designed to be the solution, not the source of the problem.

- Application-Specific Material Selection: We don't believe in "one-size-fits-all." Whether you need the ultra-high purity of virgin PTFE for semiconductor processing, the biocompatibility of a specific grade for medical devices, or the enhanced durability for an industrial seal, we select the exact material required.

- Precision Fabrication: Our manufacturing process is obsessed with integrity. By ensuring components are free from internal stress, voids, and surface imperfections, we eliminate the failure points that cause particle shedding and contamination in lesser-quality parts. This guarantees that the component remains truly inert, even under extreme operating conditions.

A KINTEK component isn't just a piece of plastic. It's the physical embodiment of the solution—a tool designed from the ground up to prevent the very degradation that was causing your system to fail.

Beyond the Fix: From Constant Troubleshooting to Fearless Innovation

Once you replace a flawed, generic component with a precision-engineered one, something transformative happens. The constant, low-level anxiety of "what will fail next?" disappears. The resources once spent on troubleshooting are freed up.

Suddenly, your team can stop firefighting and start innovating.

- For Semiconductor Engineers: You can push your process windows, exploring higher temperatures or more aggressive etch chemistries to increase throughput and develop next-generation technology, confident that your components won't be a point of failure.

- For Medical and Lab Professionals: You can trust your results. The risk of component-leached contamination is eliminated, enabling more sensitive analyses, faster diagnostic development, and a smoother path to regulatory compliance.

- For Industrial Operators: You can extend maintenance cycles and reduce unplanned downtime, knowing your seals and liners will perform reliably for longer, dramatically improving operational efficiency and safety.

Solving this nagging component issue isn't just about fixing a problem. It's about unlocking new potential and giving your organization a durable competitive advantage.

The solution to persistent system failures is often not in adding complexity, but in perfecting the fundamentals. Your process deserves components that are as reliable and well-engineered as the rest of your system. If you're tired of chasing ghosts and want to ensure material integrity is a strength, not a weakness, let's talk about your specific challenge. Contact Our Experts.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

- Custom PTFE Volumetric Flasks for Advanced Scientific and Industrial Use

- Custom PTFE Teflon Balls for Advanced Industrial Applications

Related Articles

- How PTFE Solves Critical Industrial Challenges Through Material Superiority

- When "Chemically Inert" Isn't Enough: The Hidden Cause of PTFE Component Failure

- The PTFE Paradox: Why the 'Perfect' Material Fails—And How to Make It Work

- The Physics of a Perfect Fit: How PTFE Eliminates an Athlete's Hidden Distractions

- The Unseen Guardian: How PTFE's Molecular Shield Protects Our Most Critical Systems