It's a scenario countless engineers and plant managers know by heart. A critical production line—perhaps for high-purity chemicals or semiconductor manufacturing—grinds to a sudden halt. The culprit? A failed seal, slide plate, or liner. The frustration is immense because you chose the part specifically for its "high-performance" material: PTFE, or Teflon. It was supposed to be chemically inert and ultra-slippery. It was supposed to be the solution, not the problem. Now, a multi-million dollar process is down, a batch might be contaminated, and you're left wondering, "What went wrong?"

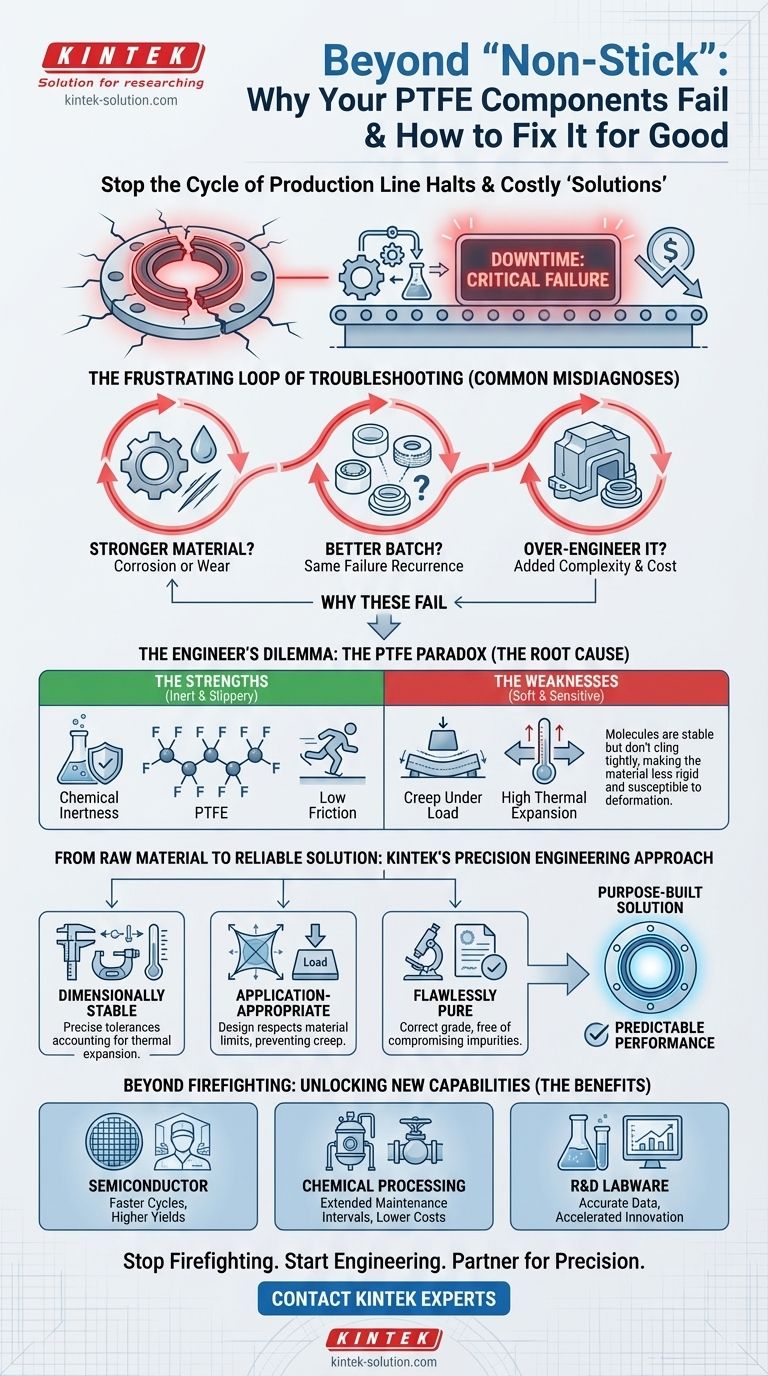

The Frustrating Loop of Troubleshooting

This initial failure often kicks off a costly and time-consuming cycle of "solutions" that don't solve anything. The conversation in the engineering meeting is always the same.

- "Maybe we need a stronger material." So, you try a harder plastic or even a specialized metal alloy. The new component doesn't deform, but it quickly corrodes from the aggressive process chemicals or its friction causes unacceptable wear on other parts. The problem is now different, but the line is still failing.

- "Perhaps it's a quality issue." You switch PTFE suppliers, hoping for a "better batch." Yet, a few weeks or months later, the same failure occurs. The issue is more persistent than simple material quality.

- "Let's over-engineer it." The team spends weeks designing a complex new assembly to shield the PTFE component, adding unnecessary complexity and maintenance points to the system.

Each attempt burns through budget, consumes valuable engineering hours, and delays production schedules. These repeated failures erode confidence in your equipment and processes. The true cost isn't just the price of a replacement part; it's the millions in lost production, the risk to product quality, and the drain on your most valuable resource: your team's time and focus.

The Engineer's Dilemma: When a Material’s Strength Becomes Its Weakness

The reason these common fixes fail is that they misdiagnose the problem. The issue isn't that PTFE is a bad material. The issue is that it's often treated like a simple, magic bullet when it is, in fact, a highly specialized tool with critical design trade-offs.

The core of the problem lies in a paradox at the heart of PTFE's molecular structure.

The Truth About PTFE's Properties

The same carbon-fluorine bonds that give PTFE its legendary chemical inertness and low-friction, non-stick surface also result in a relatively soft material. Think of it this way: the molecules are so stable and non-reactive that they don't cling tightly to one another, making the bulk material less rigid than metals or many other polymers.

This creates a fundamental engineering conflict:

- You choose it for chemical resistance, but it can fail under mechanical stress. PTFE is susceptible to "creep"—a slow, permanent deformation when placed under a persistent load. If you use a standard PTFE seal in a high-pressure application without the right design, it will eventually deform and leak.

- You choose it for its low friction, but it can fail from temperature changes. PTFE expands and contracts with heat far more than the metal parts it's often bolted to. A part that fits perfectly at room temperature might become too tight and bind, or too loose and fail, at its operating temperature.

Your "solutions" were failing because they only addressed one side of the equation. The metal part solved the strength problem but failed the chemical test. The supplier switch did nothing because the root cause was the misapplication of the material, not the material itself. You were using a world-class screwdriver as a clumsy hammer.

From Raw Material to Reliable Solution: The Power of Precision

To break this cycle, you don't need a different material. You need a different approach. The solution is not simply to select PTFE, but to engineer a PTFE component specifically for the unique combination of stresses in your application.

This is where a component becomes more than just a piece of plastic. It becomes a purpose-built solution. To truly solve the problem, you need a tool that is:

- Dimensionally Stable: It must be manufactured to precise tolerances that account for thermal expansion, ensuring it performs flawlessly across your full temperature range.

- Application-Appropriate: The design must respect the material's mechanical limits, preventing creep and premature failure under load.

- Flawlessly Pure: The material itself must be the correct grade, free of impurities that could compromise its integrity or your process.

At KINTEK, we aren't just material suppliers; we are precision fabricators. We built our expertise on this deep understanding of PTFE's engineering trade-offs. Our process is designed to directly address the root causes of failure:

- When we see a high-load application, we don't just supply a standard PTFE part. We work with you on a design that minimizes stress or recommend a filled grade of PTFE that offers enhanced mechanical strength without sacrificing chemical resistance.

- Our precision production capabilities mean we account for thermal expansion from the start. We deliver a component that fits and functions not just on the workbench, but inside your machine at its operating temperature.

Our components are the result of knowing that in demanding industries like semiconductor, medical, and chemical processing, success is measured in micrometers and defined by reliability.

Beyond Firefighting: What Becomes Possible with Predictable Performance

When you finally solve this recurring component failure, the impact is far greater than just fixing one problem. You reclaim resources, unlock new capabilities, and move your entire operation forward.

Imagine what you could do:

- In Semiconductor: Run more aggressive, faster cleaning cycles with complete confidence in your seals and liners, directly improving wafer throughput and yield.

- In Chemical Processing: Extend planned maintenance intervals from every six months to every two years, slashing operational costs and dramatically increasing production uptime.

- In R&D: Trust that your PTFE labware is truly inert and will not leach, warp, or react, ensuring the accuracy of your data and accelerating the pace of innovation.

By replacing a recurring problem with a predictable, reliable solution, you empower your engineering team to stop firefighting and start focusing on the next-generation products and process improvements that drive your business forward.

This shift from reactive maintenance to proactive excellence begins with choosing not just the right material, but the right partner. If you're ready to move beyond "good enough" and solve your most demanding application challenges, our team is here to help you engineer the right solution. Let's discuss the specifics of your project and how a precision-crafted component can make all the difference. Contact Our Experts.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Customizable PTFE Rods for Advanced Industrial Applications

- Custom PTFE Volumetric Flasks for Advanced Scientific and Industrial Use

- Custom PTFE Square Trays for Industrial and Laboratory Use

Related Articles

- The PTFE Paradox: Why the 'Perfect' Material Fails—And How to Make It Work

- Your "Inert" PTFE Component Might Be the Real Source of System Failure

- The Physics of Trust: Why PTFE Is the Bedrock of High-Stakes Electronics

- The Unseen Guardian: How PTFE's Molecular Shield Protects Our Most Critical Systems

- How PTFE Solves Critical Industrial Challenges Through Material Superiority