It’s a familiar, sinking feeling. You’re at the final stage of a delicate process, ready to analyze a sample that took days—or even weeks—to prepare. You carefully decant the liquid from its storage bottle, only to see a stubborn, visible film left behind, clinging to the inner walls.

Just like that, your quantitative analysis is compromised. The concentration is off, the results are invalid, and the expensive, time-consuming work must be done all over again.

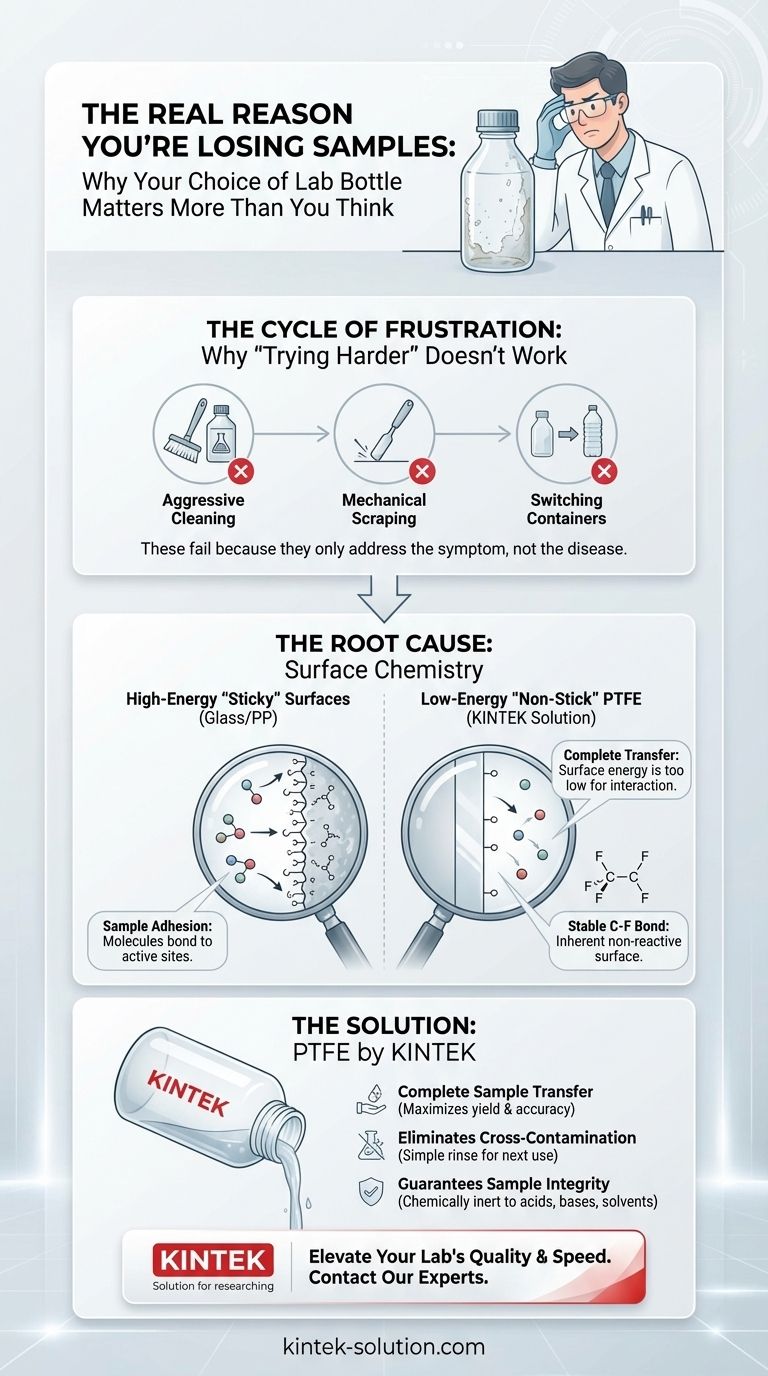

The Cycle of Frustration: Why "Trying Harder" Doesn't Work

This isn't a rare accident; it's a chronic headache in high-purity environments, from pharmaceutical R&D and trace analysis labs to semiconductor fabrication plants. Every time a sample adheres to a container, you lose valuable material and introduce a potential source of contamination for the next batch.

In response, teams often resort to a series of familiar but flawed tactics:

- Aggressive Cleaning: Using harsh solvents or acids to scrub containers clean. This not only increases costs and waste but also risks introducing new chemical impurities that can interfere with future work.

- Mechanical Scraping: Attempting to physically remove the residue, which can scratch glass or plastic surfaces, creating even more sites for future samples to stick.

- Switching Container Types: Moving from a borosilicate glass bottle to one made of polypropylene (PP), hoping for a different outcome, only to find the problem persists.

- Accepting the Loss: Simply factoring in a certain percentage of sample loss as an unavoidable "cost of doing business."

These "solutions" fail because they only address the symptom, not the disease. The business consequences are significant and measurable: wasted high-value reagents, delayed project timelines, inflated R&D budgets, and—worst of all—unreliable data that leads to poor decisions and costly production failures.

The Root Cause: It's Not Your Technique, It's Surface Chemistry

The persistent struggle with sample adhesion isn't due to poor lab technique or faulty equipment. It is a fundamental problem of surface chemistry.

Think of conventional container materials like glass or standard plastics as having "sticky" surfaces at a microscopic level. Their molecular structures have a high surface energy, characterized by countless active sites that are eager to bond with other molecules. When your sample comes into contact with these walls, its molecules are naturally attracted and adhere, like tiny magnets. Rinsing with a solvent is a fight against this strong molecular attraction.

This is why switching from one type of "sticky" material (like glass) to another (like PP) doesn't solve the core issue. You're just trading one set of problems for another.

Now, imagine a container whose surface is chemically aloof. It has no interest in interacting with your sample. Its surface energy is so low that other molecules simply slide right off. This isn't a fantasy; it's the defining principle of Polytetrafluoroethylene (PTFE).

The unique stability of the carbon-fluorine bond in PTFE creates an exceptionally low-energy, non-reactive surface. It's not a coating; it's the inherent nature of the material itself. It doesn't have the molecular "hands" to grab onto your sample. This is why PTFE is famously non-stick, and why it's the key to permanently solving this problem.

The Right Tool for the Job: Solving Chemistry with Chemistry

To truly overcome the challenges of sample loss and cross-contamination, you don't need a better cleaning protocol. You need a container built from a material that is, by its very nature, non-interactive. You need a tool designed with this fundamental chemistry in mind.

This is precisely why KINTEK manufactures high-precision PTFE labware. Our PTFE bottles and components are not a random product; they are the logical solution born from a deep understanding of these exact failure points. They are engineered to solve the problem at its root.

- Ensuring Complete Sample Transfer: The ultra-low surface energy of our PTFE bottles means that liquids, powders, and slurries pour out completely, leaving virtually no residue behind. This maximizes your yield and guarantees the accuracy of your quantitative work.

- Eliminating Cross-Contamination: Because nothing sticks, a simple rinse is often all that's needed to prepare the bottle for its next use. The risk of a previous batch contaminating a new one is virtually eliminated, ensuring the purity of your results.

- Guaranteeing Sample Integrity: The same chemical inertness that makes PTFE non-stick also makes it resistant to nearly all acids, bases, and solvents. Your sample remains pure, with no risk of leaching from the container walls, even during long-term storage or aggressive processing.

Beyond the Fix: Unlocking New Levels of Purity and Efficiency

Once you eliminate the constant worry of sample interaction, you stop spending time managing problems and start unlocking new potential. Your team is free to focus on innovation rather than repetition.

With a reliable foundation of precision PTFE components, you can:

- Trust Your Trace Analysis Data: Confidently measure elements in the parts-per-billion range without worrying about contaminants leaching from glass containers.

- Handle Aggressive Chemicals Safely: Work with the ultra-pure acids and solvents required for semiconductor manufacturing, knowing your container won't degrade or contaminate the process.

- Accelerate R&D Cycles: Reduce the need for repeat experiments caused by sample loss or contamination, getting products to market faster.

- Improve Production Yield: Enhance the reliability of quality control checks, leading to more consistent and profitable manufacturing runs.

Solving this single, persistent issue doesn't just make lab work easier; it elevates the quality, speed, and reliability of your entire operation.

Your most critical applications demand more than just a container; they require a solution engineered for purity and precision. If you're tired of battling sample loss and want to discuss how to build a more reliable process for your unique project, our team is here to help. Let's talk about the specific challenges you're facing and how precision-fabricated PTFE can provide a definitive solution. Contact Our Experts.

Visual Guide

Related Products

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

- Custom PTFE Bottles for Diverse Industrial Applications

- Custom PTFE Volumetric Flasks for Advanced Scientific and Industrial Use

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Customizable PTFE Seals Filter Holders for Versatile Applications

Related Articles

- The Fluorine Fortress: How PTFE's Molecular Simplicity Creates Unrivaled Performance

- The Specialist's Dilemma: Understanding the Critical Trade-offs of PTFE-Lined Valves

- The Hidden Cost of Chemical Containers: Why Yours Are Failing and How to Fix It

- Beyond Sanitization: Why Your Material Choice Is the Real Key to Preventing Contamination

- The Precision Trap: Understanding the Hidden Trade-offs of PTFE-Lined Globe Valves