A Tale of Two Priorities

Imagine an engineer at a specialty chemical plant. Her task is to specify a valve that can precisely throttle the flow of a highly corrosive acid. The obvious choice, the textbook answer, is a PTFE-lined globe valve. It offers unparalleled chemical resistance and the exact throttling capability she needs.

She signs off on the purchase order. The problem is solved.

Or is it?

What isn't immediately apparent on the spec sheet is the series of compromises this "perfect" solution entails. This decision, like so many in engineering, isn't about finding a flawless tool, but about consciously accepting a specific set of trade-offs. The danger lies not in the compromise itself, but in failing to understand its full cost.

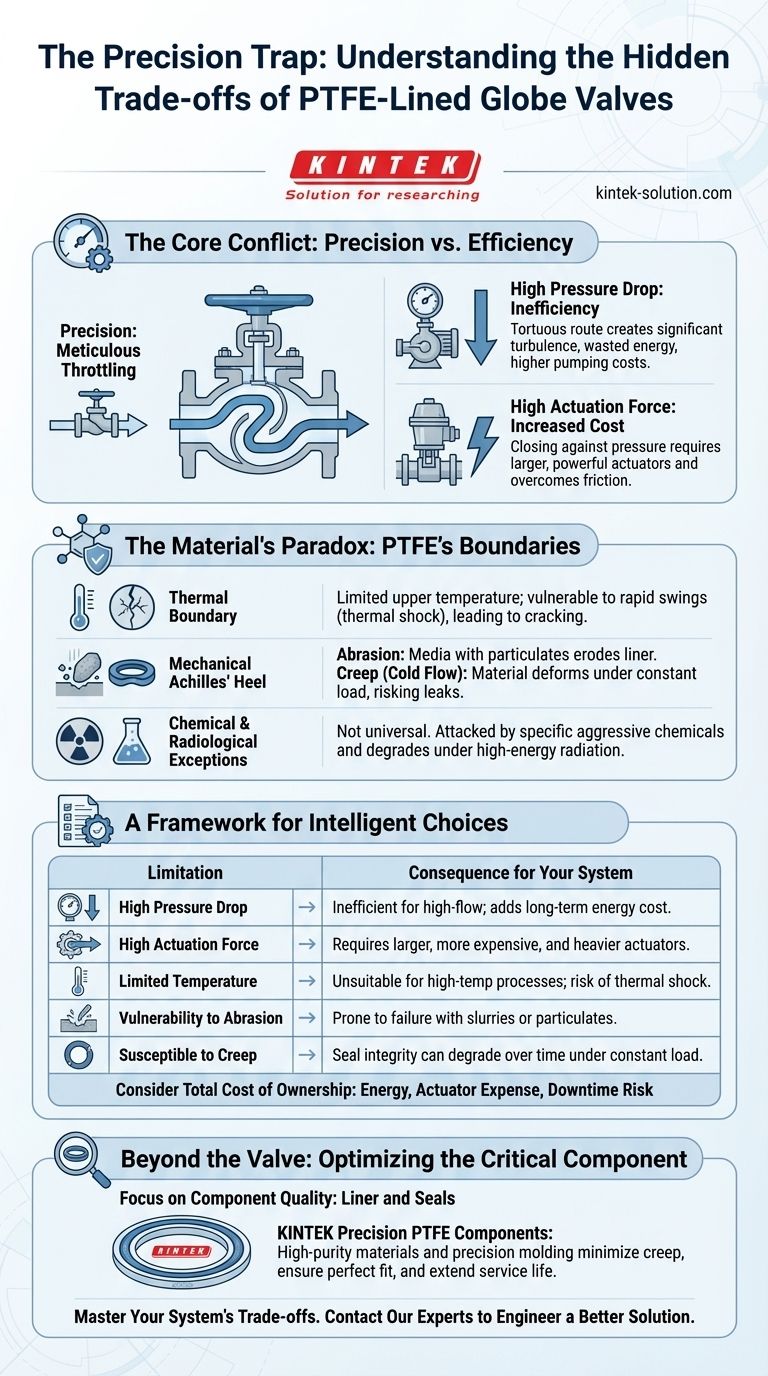

The Core Conflict: Precision vs. Efficiency

The primary virtue of a globe valve is also the source of its greatest weakness. Its internal design is intentionally obstructive.

To achieve precise control, the valve forces fluid through a complex, Z-shaped path, directing it against the flat face of a disc. This design is what allows for meticulous, gradual adjustments to flow rate.

But this elegance comes at a price.

The Inevitable Toll: High Pressure Drop

Unlike the straight, unimpeded path of a ball or gate valve, the globe valve's tortuous route creates significant turbulence and resistance. The result is a substantial pressure drop across the valve.

For a system designed for high-volume transfer, this is pure inefficiency—wasted energy that translates into higher pumping costs over the lifetime of the equipment.

The Price of Control: High Actuation Force

Pushing a disc squarely into a high-pressure flow requires significant force. The line pressure works directly against the closing mechanism.

This reality, compounded by the friction from the PTFE sealing components, demands larger, more powerful, and more expensive actuators. A simple quarter-turn on a ball valve is replaced by a powerful mechanism, whether manual or automated, that can overcome the system's inherent resistance.

The Material's Paradox: PTFE's Boundaries

The PTFE liner grants the valve near-invincibility against chemical attack. It’s a remarkable material, but it is not a magical one. It has its own physical boundaries that define the valve's true operating envelope.

The Thermal Boundary

PTFE has a strict upper temperature limit, softening and losing its mechanical integrity long before its technical melting point of 326°C. Its practical service ceiling is often closer to 200°C. It is also vulnerable to thermal shock—rapid, extreme temperature swings that can cause cracking or delamination.

The Mechanical Achilles' Heel: Abrasion and Creep

While chemically tough, PTFE is a physically soft material. This creates two distinct failure modes:

- Abrasion: Media containing solid particulates or slurries can quickly erode the soft liner, compromising the valve's integrity and leading to catastrophic failure.

- Creep (Cold Flow): Under the constant compressive load of the valve seat, the PTFE material can slowly deform over time. This "cold flow" can cause the seal to fail, leading to leaks that are difficult to diagnose until they become critical.

This is where the quality of the component itself becomes paramount. Off-the-shelf liners may meet basic chemical specs, but they often fail prematurely due to creep. Precision-molded components, engineered from high-purity PTFE, are essential for resisting the subtle, persistent forces that lead to long-term failure.

The Chemical and Radiological Exceptions

Despite its broad resistance, PTFE is not universally compatible. It can be attacked by a small list of aggressive chemicals like elemental fluorine and strong fluorinating agents. It also degrades under high-energy radiation, which shatters its molecular structure and causes embrittlement.

A Framework for Intelligent Choices

Choosing a PTFE-lined globe valve means accepting its trade-offs. The decision requires looking beyond the immediate problem of throttling a corrosive fluid and considering the entire system's health.

| Limitation | Consequence for Your System |

|---|---|

| High Pressure Drop | Inefficient for high-flow; adds long-term energy cost. |

| High Actuation Force | Requires larger, more expensive, and heavier actuators. |

| Limited Temperature | Unsuitable for high-temp processes; risk of thermal shock. |

| Vulnerability to Abrasion | Prone to failure with slurries or particulates. |

| Susceptible to Creep | Seal integrity can degrade over time under constant load. |

This isn't just about the valve's initial cost. It's about the total cost of ownership—including energy consumption, actuator expense, and the risk of downtime from a premature liner failure.

Beyond the Valve: Optimizing the Critical Component

While the globe valve's design trade-offs are fixed, its material-related failures are not. The integrity of the system often comes down to the quality of the components you can't easily see: the liner and the seals.

This is where focusing on the specific component, not just the assembly, provides a crucial advantage. At KINTEK, we specialize in the precision manufacturing of PTFE components for the most demanding industries. By engineering custom seals and liners, we directly address the material's inherent weaknesses. Our focus on high-purity materials and precision molding minimizes creep and ensures a perfect fit, extending the service life of critical equipment and preventing failures that generic, off-the-shelf parts can't.

Ultimately, building a robust system isn't about finding a perfect, one-size-fits-all solution. It's about understanding the compromises of each component and choosing the highest quality where it matters most. To master your system, you must first master its trade-offs.

If you are facing challenges with the performance and longevity of your critical fluid handling components, let's engineer a better solution. Contact Our Experts

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

- Custom PTFE Square Trays for Industrial and Laboratory Use

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

Related Articles

- Why Your High-Performance PTFE Parts Fail—And Why It's Not the Material's Fault

- Beyond "Non-Stick": Why Your PTFE Components Fail and How to Fix It for Good

- The Unseen Guardian: How PTFE's Molecular Shield Protects Our Most Critical Systems

- When "Chemically Inert" Isn't Enough: The Hidden Cause of PTFE Component Failure

- The PTFE Paradox: Why the 'Perfect' Material Fails—And How to Make It Work