You’ve done everything by the book. The entire processing line was stripped, scrubbed, and sanitized. Yet, the lab report comes back with the same dreaded result: another batch showing unacceptable microbial counts. It’s a costly and frustrating mystery that plays out in food, dairy, and pharmaceutical plants everywhere—a contamination nightmare that seems to have no clear cause and no permanent solution.

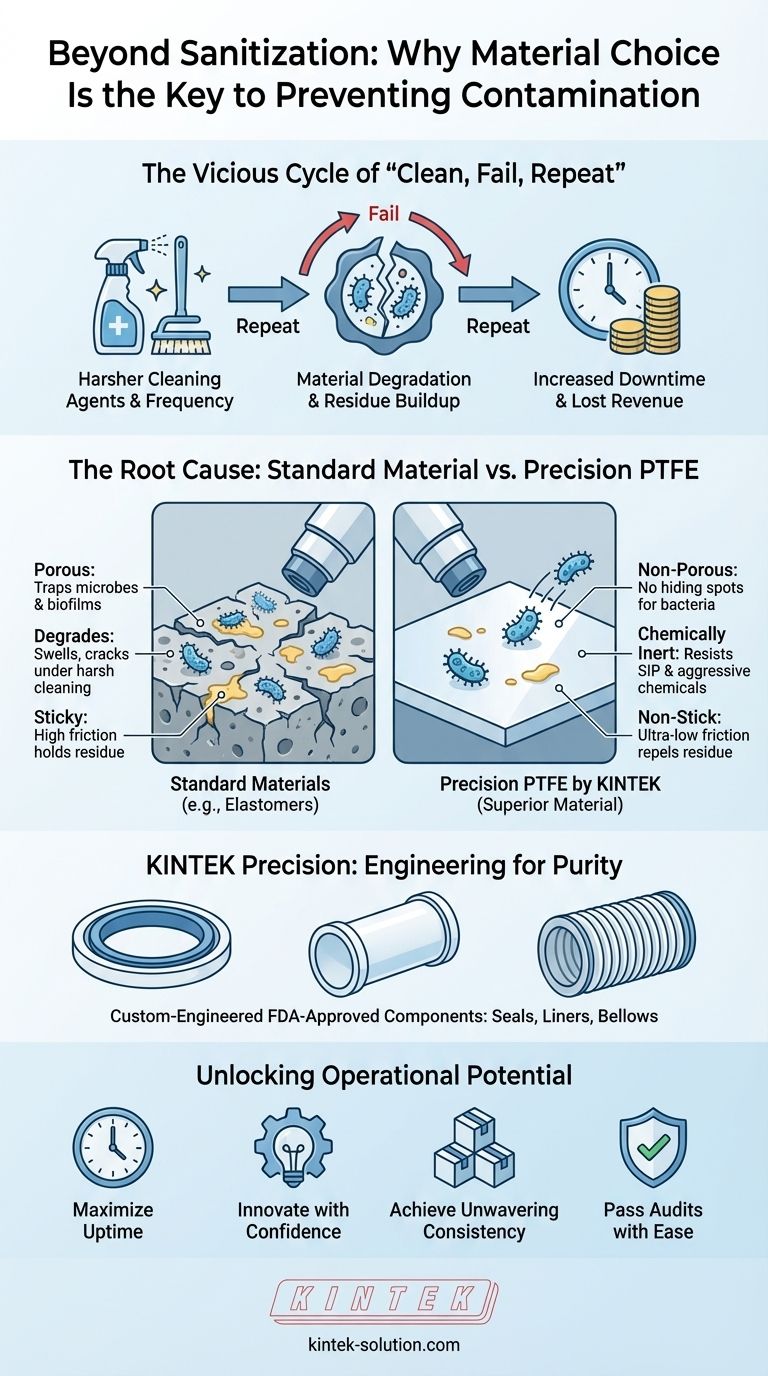

The Vicious Cycle of "Clean, Fail, Repeat"

When faced with these "phantom" contamination issues, the typical response is to escalate the assault. Teams often find themselves trapped in a reactive loop:

- Using harsher cleaning agents: If the standard sanitizer isn't working, the next step is often a more aggressive chemical, which can degrade seals and gaskets over time.

- Increasing cleaning frequency and duration: This leads to more production downtime, directly impacting output and operational efficiency. A line that is being cleaned is a line that isn't making money.

- Replacing components more often: Constantly swapping out seals, liners, and gaskets feels proactive, but it’s a costly, labor-intensive fix that only treats the symptom, not the underlying disease.

The business consequences are severe and quantifiable. Every discarded batch represents lost revenue in raw materials and production time. Extended downtime delays product launches and strains supply chains. Worst of all, the persistent risk of a product recall looms, threatening regulatory penalties and irreversible damage to your brand's reputation.

You are fighting a battle you can't seem to win, but what if the enemy isn't your cleaning protocol, but the very materials you're trying to clean?

It’s Not Your Process, It’s Your Parts: The Material Science of Contamination

The core conflict is a widespread misunderstanding: many standard materials used for seals and liners, like certain elastomers or commodity plastics, are fundamentally incompatible with the goal of perfect, sustained hygiene.

At a microscopic level, these materials are not as smooth or inert as they appear.

- They are porous: Under a microscope, their surfaces are filled with microscopic nooks and crannies. These are perfect hiding spots for bacteria, forming biofilms that are nearly impossible to remove with standard cleaning.

- They degrade: When exposed to the aggressive cleaning agents and high temperatures required for sanitization, these materials can swell, crack, or become brittle. This degradation not only shortens their lifespan but also creates even more surface imperfections for contaminants to colonize.

- They are "sticky": Compared to superior alternatives, their surfaces have a higher friction, allowing product residue to adhere more easily. This residue can become a food source for bacteria, fueling the contamination cycle.

This is the fundamental truth: You cannot sanitize a surface that is designed to trap contaminants. Your aggressive cleaning protocols are a losing strategy because they are aimed at a material that actively works against them. The real root cause of recurring contamination is a material choice that represents a false economy—cheaper up front, but astronomically more expensive in downtime, lost product, and risk.

Engineering for Purity: The Role of Precision PTFE Components

To truly solve this problem, you don't need a more powerful cleaning agent; you need a better material. You need components fabricated from a material that is inherently non-porous, chemically inert, and exceptionally non-stick.

That material is Polytetrafluoroethylene (PTFE).

PTFE isn't just another plastic. It is an engineering polymer whose properties directly counter the root causes of contamination:

- Its surface is extremely non-porous and smooth, offering no microscopic harbors for bacteria to hide.

- It is one of the most chemically inert substances known, meaning it will not degrade or react when exposed to the harshest steam-in-place (SIP) cycles or sanitizing chemicals.

- It has an incredibly low coefficient of friction—it's the scientific reason for its famous non-stick quality. Product residue and microbes simply can't get a grip.

However, the raw potential of PTFE is only realized when it is fabricated with absolute precision. A poorly manufactured PTFE seal or liner can create its own points of failure. This is where KINTEK's expertise becomes critical. We are not just material suppliers; we are precision fabricators. We specialize in transforming high-purity, FDA-approved PTFE into custom components—seals, liners, bellows, and labware—that are engineered to the exact tolerances your critical application demands. Our components aren't just a part of your machine; they are an active defense system, designed from first principles to guarantee purity.

Beyond Damage Control: Unlocking New Operational Potential

When you stop fighting a losing battle against the wrong materials, you unlock significant new potential for your entire operation. Solving the recurring contamination problem isn't just about avoiding failure; it's about creating new opportunities for success.

- Maximize Uptime: With components that withstand aggressive cleaning and prevent residue buildup, you can reduce cleaning cycle times and frequency, adding valuable hours of production back into your schedule.

- Innovate with Confidence: You can explore more complex product formulations or more demanding processing conditions, knowing your equipment's contact surfaces won't be a point of failure.

- Achieve Unwavering Consistency: By eliminating a major variable in your process, you ensure greater batch-to-batch consistency, higher yields, and a more predictable, profitable operation.

- Pass Audits with Ease: You move from a position of constant worry to one of confident compliance, with a system that is demonstrably designed for hygiene and safety.

Solving a persistent technical issue with the right component is just the first step. The ultimate goal is to build a more resilient, efficient, and innovative operation. If you're ready to break the "clean, fail, repeat" cycle and discuss how precision-engineered components can solve your most stubborn challenges, our team of experts is here to help. Contact Our Experts.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

- Custom PTFE Volumetric Flasks for Advanced Scientific and Industrial Use

- PTFE Chemical Solvent Sampling Spoon

Related Articles

- The Physics of a Perfect Fit: How PTFE Eliminates an Athlete's Hidden Distractions

- Beyond "Non-Stick": Why Your PTFE Components Fail and How to Fix It for Good

- The Physics of Trust: Why PTFE Is the Bedrock of High-Stakes Electronics

- The Unseen Workhorse: Why PTFE Is the Default Choice for Impossible Problems

- The Unseen Guardian: How PTFE's Molecular Shield Protects Our Most Critical Systems