The Seduction of a Single Number

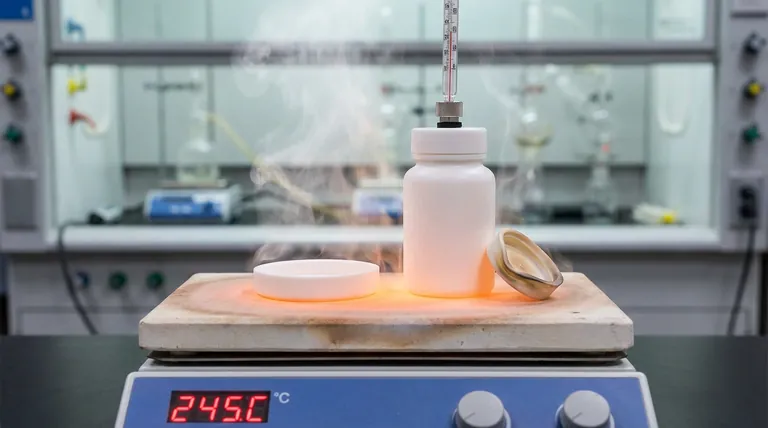

In engineering and science, we are drawn to definitive numbers. They provide a sense of certainty in a world of variables. The number associated with a PTFE bottle is often 260°C (500°F).

This figure is impressive. It speaks to a material capable of withstanding extreme conditions, from cryogenic deep freezes to high-temperature digestions. Yet, focusing on this single number is a profound psychological trap. It leads us to believe the material's capability is the system's capability.

It never is. A bottle is not just a material; it is an assembly. And the integrity of any assembly is dictated by its weakest link.

The Upper Limit: A Margin of Safety, Not Performance

The melting point of PTFE is a staggering 327°C (620°F). So why is the continuous operating limit set at a much lower 260°C?

This isn't a conservative suggestion; it's a critical safety boundary.

Long before it melts, PTFE begins to soften and lose its structural integrity. More critically, as it approaches its melting point, it can undergo thermal decomposition, releasing hazardous fluorocarbon fumes. The 260°C limit is the line where the material remains strong, stable, and chemically inert.

To cross it is to trade reliability for risk, assuming the bottle is even the limiting factor.

The Lower Limit: The Unseen Shift to Rigidity

At the other end of the spectrum, PTFE's performance is just as remarkable. It maintains its strength and toughness in cryogenic conditions down to -200°C (-328°F).

But here too, a single number hides a crucial detail. While the material works, its character changes. Below approximately -79°C (-110°F), PTFE loses its familiar flexibility. It becomes progressively more rigid.

The bottle looks the same. It feels the same in a gloved hand. But its response to a sudden impact or mechanical stress is entirely different. This is a hidden variable that requires situational awareness.

The Weakest Link: A Story of a Failed Experiment

Imagine a critical process running in a lab. A precious sample is undergoing digestion in a high-purity PTFE bottle at 210°C, well within the bottle's advertised limit. Suddenly, the seal fails. The sample is contaminated, the experiment is lost, and the integrity of the lab's environment is compromised.

What went wrong?

The post-mortem reveals the bottle is perfectly fine. The failure was the cap. Its liner, a standard component, was only rated for 180°C.

This is not a material failure. It is a systems thinking failure. Our minds tend to anchor on the most prominent component—the expensive, high-performance bottle—and overlook the smaller, supporting parts. The entire assembly, however, performs at the level of its lowest-rated component.

The Inescapable Laws of Physics

There is another invisible actor in this system: pressure.

Heating the contents of any sealed container builds internal pressure. This physical force can cause mechanical failure—warping the bottle or blowing out a seal—long before the material's thermal limit is reached. The system is not just the hardware; it includes the process being performed within it.

A Checklist for System Integrity

To ensure safety and repeatability, we must shift our perspective from a single component to the entire operational system.

- Scrutinize the Full Assembly: What is the temperature rating of the bottle? And the cap? And the cap liner? The lowest number is your true maximum operating temperature.

- Account for Internal Pressure: If your process involves heating in a sealed or semi-sealed container, have you calculated the potential pressure increase?

- Respect the Margins: Treat the 260°C limit as a hard ceiling, not a target. Ensure proper ventilation when operating near the upper temperature range.

- Handle with Awareness: At cryogenic temperatures, recognize that the material is more brittle. Protect it from mechanical shock.

This systems-level thinking is at the core of reliable scientific and industrial processes. A component's material specification is only the starting point; its value is realized when it performs flawlessly within the larger assembly.

At KINTEK, we manufacture high-integrity PTFE components—from labware and liners to mission-critical seals—with an understanding that every part contributes to the system's success. We focus on precision and material purity because we know that in specialized industries, the weakest link can't be tolerated. Whether you need a standard solution for cryogenic storage or a custom-fabricated bottle and cap assembly designed to meet a specific thermal and pressure profile, we provide components built for the integrity of your entire operation.

To ensure your equipment's performance matches your process's demands, Contact Our Experts.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Bottles for Diverse Industrial Applications

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

- Custom PTFE Volumetric Flasks for Advanced Scientific and Industrial Use

Related Articles

- The Asymmetric Cost of Failure: Why Precision PTFE Is Your Last Line of Defense

- The Unseen Component: How PTFE Became the Bedrock of Medical Device Reliability

- The Unseen Workhorse: Why PTFE Is the Default Choice for Impossible Problems

- When 'Chemically Inert' Isn't Enough: Why Your PTFE Components Fail and How to Prevent It

- Why Your High-Performance PTFE Parts Fail—And Why It's Not the Material's Fault