It’s a scenario familiar to many process engineers and lab managers: a critical operation is halted, and you trace the problem to a failed seal, liner, or valve seat. The component is made from PTFE—the supposed gold standard for chemical resistance. It should have been indestructible in your application, yet here it is: brittle, discolored, or corroded.

Your first thought is logical: it must be a defective part. A bad batch of material, perhaps? A flaw in the manufacturing? You order a replacement, but the mystery remains.

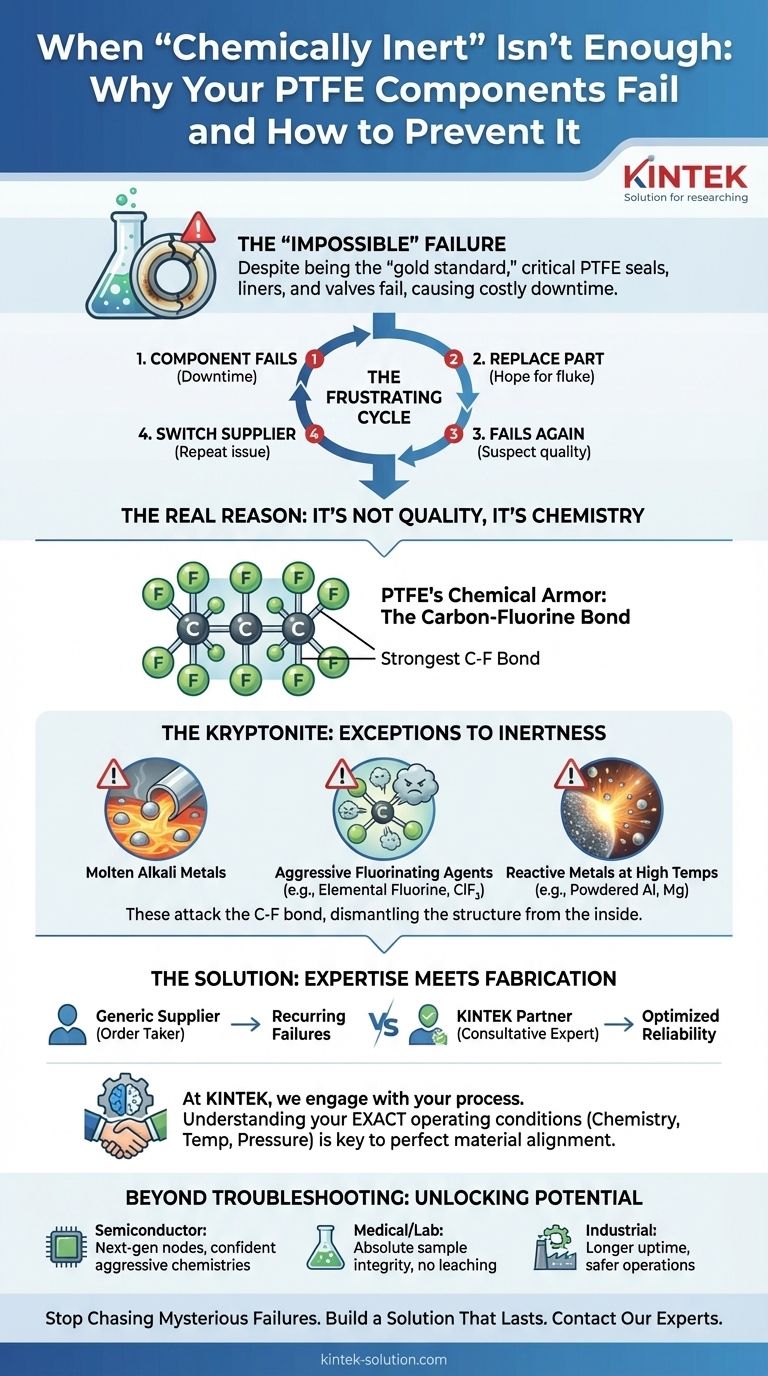

The Frustrating Cycle of Replacement and Doubt

This "impossible" failure is more common than you think. Across semiconductor, medical, and advanced industrial sectors, brilliant teams have been stumped by the paradox of an "invincible" material failing.

The typical response is a costly and frustrating cycle:

- You replace the component, hoping it was a one-off fluke.

- When it fails again, you suspect a quality issue and switch PTFE suppliers.

- Weeks or months later, the new supplier's part fails in the exact same way.

Each cycle costs more than just the price of a component. It leads to expensive downtime, scrapped product batches, derailed R&D timelines, and—in the worst cases—potential safety hazards from chemical leaks. The problem isn't your supplier's quality control; it's a fundamental, and often overlooked, aspect of PTFE's chemistry.

The Real Reason for Failure: It's Not Quality, It's Chemistry

The belief that PTFE is universally inert is a helpful simplification, but it's not the whole truth. The issue isn't a defect in the material; it's an incompatibility between the material and a very specific, aggressive chemical environment that was thought to be safe.

PTFE’s Chemical Armor: The Carbon-Fluorine Bond

PTFE's legendary resistance comes from its molecular structure. It consists of a long carbon chain completely shielded by a tightly packed sheath of fluorine atoms. The bond between carbon and fluorine (C-F) is one of the strongest in organic chemistry.

Think of it as a nearly perfect suit of molecular armor. This fluorine sheath protects the vulnerable carbon backbone from almost all chemical attacks, which is why PTFE stands up to the vast majority of acids, bases, and solvents.

The Kryptonite: A Shortlist of Exceptions

However, even the strongest armor has vulnerabilities. A handful of extremely reactive substances have enough energy to break the powerful C-F bond and dismantle the PTFE structure from the inside out. These are not your everyday lab chemicals; they are highly aggressive agents, often under specific conditions:

- Molten Alkali Metals: Chemicals like molten sodium or potassium are powerful enough to physically strip fluorine atoms from the polymer, causing it to degrade rapidly.

- Aggressive Fluorinating Agents: It’s counterintuitive, but elemental fluorine, chlorine trifluoride (ClF₃), and other potent fluorinating agents can attack PTFE, especially at high temperatures and pressures.

- Certain Reactive Metals at High Temperatures: Finely powdered aluminum or magnesium can react with PTFE, but typically only when approaching the material's melting point.

The reason replacing the part or switching suppliers fails is now clear: you were fighting the wrong battle. You were treating it like a quality problem when it was, in fact, a chemical application problem. Any high-quality PTFE component will have the same fundamental chemistry and will fail in the same way under these specific conditions.

The Right Tool for the Job: Material Expertise Meets Precision Fabrication

Therefore, the only sustainable solution is to ensure your component is designed with a full understanding of your exact operating conditions—including chemistry, temperature, and pressure. Preventing failure isn't about finding "better" PTFE; it's about applying material science expertise to your specific challenge.

This is where a true manufacturing partner separates itself from a simple parts supplier. A partner doesn't just take an order; they engage with your process to ensure the material is perfectly suited for the application.

At KINTEK, this consultative approach is at the core of what we do. We specialize in manufacturing high-precision PTFE components for the world's most demanding industries. Our process begins not with a machine, but with a conversation about your application. By understanding the nuances of your chemical environment, we ensure that the PTFE grade, design, and fabrication process are perfectly aligned to deliver unwavering performance and reliability. We build parts that are not just made to spec, but engineered to succeed.

Beyond Troubleshooting: Unlocking New Potential

When you can finally trust your components not to fail unexpectedly, it changes everything. You move from a reactive state of constant troubleshooting to a proactive state of innovation and optimization.

- For Semiconductor Fabs: It means pushing to more aggressive etch and clean chemistries to develop next-generation nodes with confidence.

- For Medical and Lab Environments: It means absolute certainty in the integrity of your samples and data, free from the risk of material leaching or degradation.

- For Industrial Processes: It means longer operational uptime, safer working conditions, and predictable maintenance schedules.

By solving this foundational material challenge, you unlock the freedom to focus on what truly matters: pushing the boundaries of your science and engineering.

The integrity of your most critical systems shouldn't be left to chance. True reliability comes from a partnership built on deep expertise. If you're tired of chasing down mysterious material failures and want to ensure your components are perfectly engineered for their environment, our team is ready to help. Let's discuss your specific project challenges and build a solution that lasts. Contact Our Experts.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

Related Articles

- The Physics of a Perfect Fit: How PTFE Eliminates an Athlete's Hidden Distractions

- Why Your High-Performance PTFE Parts Fail—And Why It's Not the Material's Fault

- The Unseen Workhorse: Why PTFE Is the Default Choice for Impossible Problems

- When "Chemically Inert" Isn't Enough: The Hidden Cause of PTFE Component Failure

- The Asymmetric Cost of Failure: Why Precision PTFE Is Your Last Line of Defense