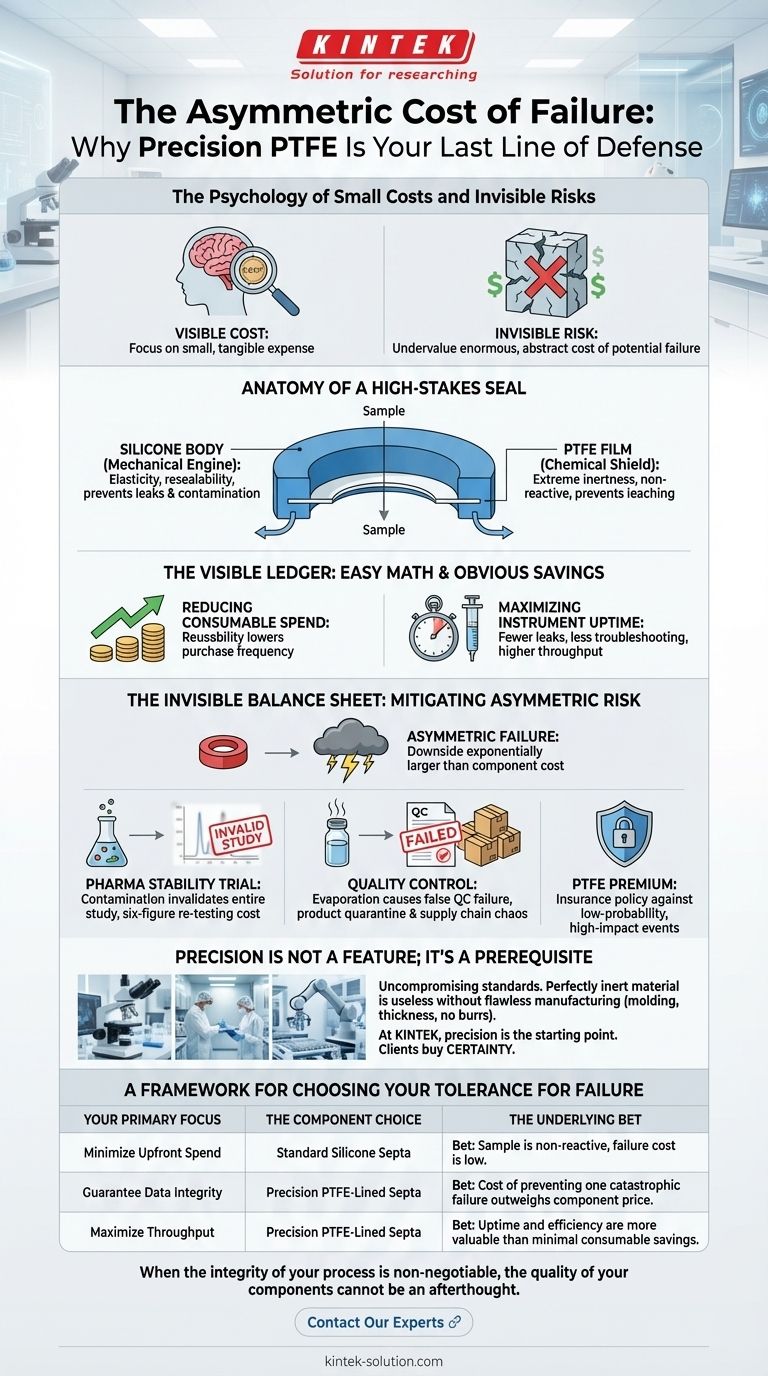

The Psychology of Small Costs and Invisible Risks

Humans are notoriously bad at pricing risk. We focus on the small, tangible cost in front of us—the line item on a purchase order—while systematically undervaluing the enormous, abstract cost of a potential failure.

This cognitive bias plays out every day in high-stakes laboratories. We might scrutinize the price of a vial septum, a component costing mere cents, yet overlook its role in safeguarding an analytical process worth millions.

This tiny, unassuming disc of material is not just a seal; it's a gatekeeper. And when it fails, the consequences are rarely proportional to its price.

Anatomy of a High-Stakes Seal

In analytical chemistry, instruments like an HPLC or GC-MS are temples of precision. The septum is the humble doorkeeper. Its function is deceptively simple: maintain a perfect, sterile seal while allowing a needle to pass through for sample extraction, and then reseal perfectly upon its exit.

To achieve this, high-performance septas are a composite marvel.

- The Silicone Body: This provides the mechanical engine. Its elasticity and flexibility allow it to be pierced repeatedly while retaining a tight seal, preventing evaporation and contamination from the outside world.

- The PTFE Film: This is the chemical shield. A microscopically thin layer of Polytetrafluoroethylene faces the sample. Its defining feature is extreme chemical inertness. It refuses to interact with, or leach into, virtually any solvent or compound it contains.

Together, they form a component engineered to solve two distinct problems at once: the mechanical challenge of sealing and the chemical challenge of non-reactivity.

The Visible Ledger: Easy Math and Obvious Savings

The most straightforward financial benefits of high-quality PTFE silicone septas are the ones you can track on a spreadsheet. They represent the first layer of value.

Reducing Consumable Spend

Unlike cheaper alternatives designed for single use, robust PTFE silicone septas can often be reused in certain applications. This directly lowers the purchase frequency and volume of lab consumables, leading to a leaner operational budget.

Maximizing Instrument Uptime

A reliable seal prevents leaks. Fewer leaks mean less time spent troubleshooting failed runs, re-prepping samples, and re-calibrating expensive machinery. In a high-throughput lab, this translates directly to more analyses per day and better asset utilization.

The Invisible Balance Sheet: Mitigating Asymmetric Risk

The real, and far greater, cost savings are realized by preventing what doesn't happen. The cost of failure is asymmetric; the downside is exponentially larger than the cost of the component itself.

Consider a late-stage pharmaceutical stability trial. A poorly chosen septum begins to leach trace impurities into a drug formulation. The contamination is subtle, but it's enough to skew the chromatography results.

The cost here is not the price of a new septum. It's the cost of invalidating the entire study. It's the six-figure expense of re-testing, the weeks of delay, and the risk of derailing a regulatory submission.

Or imagine a routine quality control test for a finished product. A leaky septum allows solvent to evaporate, artificially concentrating the sample. The batch incorrectly fails its QC check. The cost is now the investigation, the potential quarantine of a perfectly good product, and the chaos injected into the supply chain.

The premium paid for an inert PTFE layer is not an expense. It is an insurance policy against these low-probability, high-impact events.

Precision Is Not a Feature; It's a Prerequisite

The theoretical benefits of PTFE are only realized if the component is manufactured to uncompromising standards. The material science is only half the story.

A perfectly inert material is useless if the septum is improperly molded, has microscopic burrs, or varies in thickness. These seemingly minor defects can compromise the seal, negating the very purpose of the component.

This is where an obsession with manufacturing excellence becomes critical. For industries from semiconductor fabrication to medical devices, precision isn't a goal; it's the starting point. At KINTEK, we apply this philosophy to every PTFE component we produce, whether it's a standard seal, a custom liner, or specialized labware. We understand that our clients aren't just buying a part; they are buying certainty. From a single prototype to a high-volume production run, our focus is on delivering components that perform flawlessly under pressure.

A Framework for Choosing Your Tolerance for Failure

The decision of which component to use is not about "cheap" versus "expensive." It is a conscious decision about your acceptable level of risk.

| Your Primary Focus | The Component Choice | The Underlying Bet |

|---|---|---|

| Minimize Upfront Spend | Standard Silicone Septa | You are betting that your sample is non-reactive and that the cost of a potential failure is low. |

| Guarantee Data Integrity | Precision PTFE-Lined Septa | You are betting that the cost of preventing a single catastrophic failure far outweighs the component's price. |

| Maximize Throughput | Precision PTFE-Lined Septa | You are betting that instrument uptime and personnel efficiency are more valuable than minimal savings on consumables. |

Ultimately, the true cost of any component is its sticker price plus the risk it carries. In environments where precision is paramount, mitigating risk is the most powerful lever for controlling long-term costs.

When the integrity of your process is non-negotiable, the quality of your components cannot be an afterthought. Contact Our Experts

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Volumetric Flasks for Advanced Scientific and Industrial Use

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

- Custom PTFE Teflon Balls for Advanced Industrial Applications

Related Articles

- The Physics of Trust: Why PTFE Is the Bedrock of High-Stakes Electronics

- The Unseen Workhorse: Why PTFE Is the Default Choice for Impossible Problems

- The Unseen Guardian: How PTFE's Molecular Shield Protects Our Most Critical Systems

- The PTFE Paradox: Why the 'Perfect' Material Fails—And How to Make It Work

- Beyond "Non-Stick": Why Your PTFE Components Fail and How to Fix It for Good