The Hidden Points of Failure

In medical device engineering, success is often invisible. A joint brace that moves so smoothly the patient forgets it’s there. A syringe plunger that delivers a precise dose without a hint of friction. A vascular graft that the body accepts as its own.

These are triumphs of material science.

But the opposite is also true. Failure often begins at the microscopic level—at the interface between a device and human tissue, or between two moving components. It begins with friction, chemical degradation, or a subtle immune response. The biggest risks often hide in the smallest, most overlooked components.

From a psychological perspective, choosing a material for these applications isn't just a technical decision; it's an exercise in risk mitigation. Engineers are seeking certainty. They are looking for a material that quietly and reliably does its job, creating a foundation of trust for the entire system.

This is the world where Polytetrafluoroethylene (PTFE) operates.

The Physics of Trust: Deconstructing PTFE

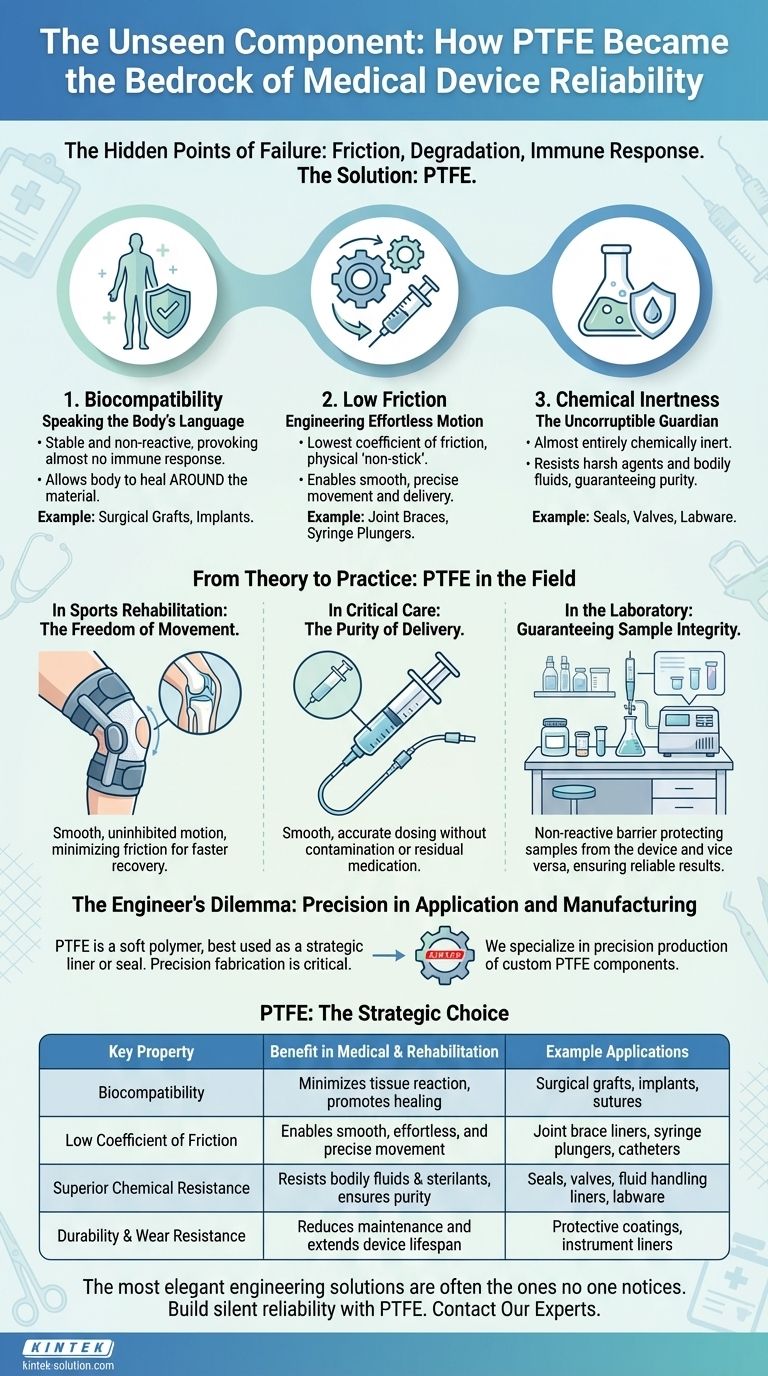

PTFE's value isn't derived from a single killer feature, but from a powerful combination of three core properties. This trio addresses the fundamental challenges of medical and rehabilitative device design.

1. Biocompatibility: Speaking the Body’s Language

The human body is an exceptionally vigilant security system. It is programmed to identify and attack foreign invaders. Most materials trigger some level of immune response, leading to inflammation, rejection, and poor patient outcomes.

PTFE is different. It is profoundly biocompatible. Its molecular structure is so stable and non-reactive that it provokes almost no reaction from human tissue. The body doesn't see it as a threat.

This "invisibility" is why it's a trusted material for implants, surgical grafts, and sutures. It allows the body to heal around the material, not against it.

2. Low Friction: Engineering Effortless Motion

Friction is the enemy of smooth, controlled movement. In a joint brace, friction causes chafing and restricts mobility, hindering recovery. In a syringe, it leads to jerky, imprecise injections.

PTFE possesses one of the lowest coefficients of friction of any solid material. It's the physical embodiment of "non-stick."

This property allows components to glide past each other—or against delicate human tissue—with minimal resistance. It's what enables the fluid motion of a high-performance brace and the flawless delivery of medication from a pre-filled syringe.

3. Chemical Inertness: The Uncorruptible Guardian

Medical environments are chemically harsh. Devices are exposed to everything from aggressive sterilization agents to complex bodily fluids. A material that degrades under this exposure compromises the safety and longevity of the entire device.

PTFE is almost entirely chemically inert. It simply does not react.

This makes it the perfect material for seals, valves, and liners in fluid and sample handling equipment. It ensures that a delicate drug formulation isn't altered by its container, and that a critical diagnostic sample isn't contaminated. It guarantees purity.

From Theory to Practice: PTFE in the Field

These properties are not just abstract concepts; they solve tangible, high-stakes problems every day in clinics, labs, and operating rooms.

In Sports Rehabilitation: The Freedom of Movement

An athlete's recovery depends on restoring natural movement. A brace lined with PTFE doesn't just support a joint; it facilitates smooth, uninhibited motion. By minimizing friction against the skin and its own components, it allows for more effective therapy and greater patient comfort, accelerating the return to peak performance.

In Critical Care: The Purity of Delivery

When administering medication, precision is paramount. PTFE components like syringe plungers and pump seals ensure that every microliter of a drug is delivered smoothly and without contamination. Its non-stick surface prevents residual medication from clinging to the device, guaranteeing accurate dosing.

In the Laboratory: Guaranteeing Sample Integrity

In diagnostics and research, the integrity of a sample is everything. PTFE labware and equipment liners create a non-reactive barrier that protects samples from the device, and the device from corrosive chemicals. This inertness is critical for achieving reliable, repeatable results.

The Engineer's Dilemma: Precision in Application and Manufacturing

Despite its advantages, PTFE is not a universal solution. It is a soft polymer, unsuited for high-load structural roles on its own. Its true power is unlocked when used strategically as a liner, a seal, or a low-friction component.

Furthermore, fabricating PTFE with the precision required for medical applications is a specialized craft. The material's unique properties make it challenging to machine and mold. This is where the choice of a manufacturing partner becomes as critical as the choice of the material itself.

High-performance devices demand components manufactured to exacting tolerances. For a material like PTFE, achieving this requires deep expertise and specialized equipment. This is the gap between a raw material and a reliable solution.

KINTEK bridges this gap. We specialize in the precision production of custom PTFE components, from seals and liners for medical instruments to specialized labware. We understand that in the medical field, performance is non-negotiable. Whether you need a single prototype or a high-volume production run, our focus is on delivering the reliability your application demands.

The table below summarizes why PTFE is the strategic choice for these sensitive applications.

| Key Property | Benefit in Medical & Rehabilitation | Example Applications |

|---|---|---|

| Biocompatibility | Minimizes tissue reaction, promotes healing | Surgical grafts, implants, sutures |

| Low Coefficient of Friction | Enables smooth, effortless, and precise movement | Joint brace liners, syringe plungers, catheters |

| Superior Chemical Resistance | Resists bodily fluids & sterilants, ensures purity | Seals, valves, fluid handling liners, labware |

| Durability & Wear Resistance | Reduces maintenance and extends device lifespan | Protective coatings, instrument liners |

The most elegant engineering solutions are often the ones no one notices. They just work, flawlessly and reliably. By understanding the unique strengths of PTFE, you can build that silent reliability into the core of your next device.

If you are ready to leverage the power of this remarkable material for your project, Contact Our Experts.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

- Custom PTFE Volumetric Flasks for Advanced Scientific and Industrial Use

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

Related Articles

- The Physics of Trust: Why PTFE Is the Bedrock of High-Stakes Electronics

- Beyond "Non-Stick": Why Your PTFE Components Fail and How to Fix It for Good

- The Physics of a Perfect Fit: How PTFE Eliminates an Athlete's Hidden Distractions

- How PTFE Solves Critical Industrial Challenges Through Material Superiority

- The PTFE Paradox: Why the 'Perfect' Material Fails—And How to Make It Work