The Silent Partner in a Billion-Dollar Process

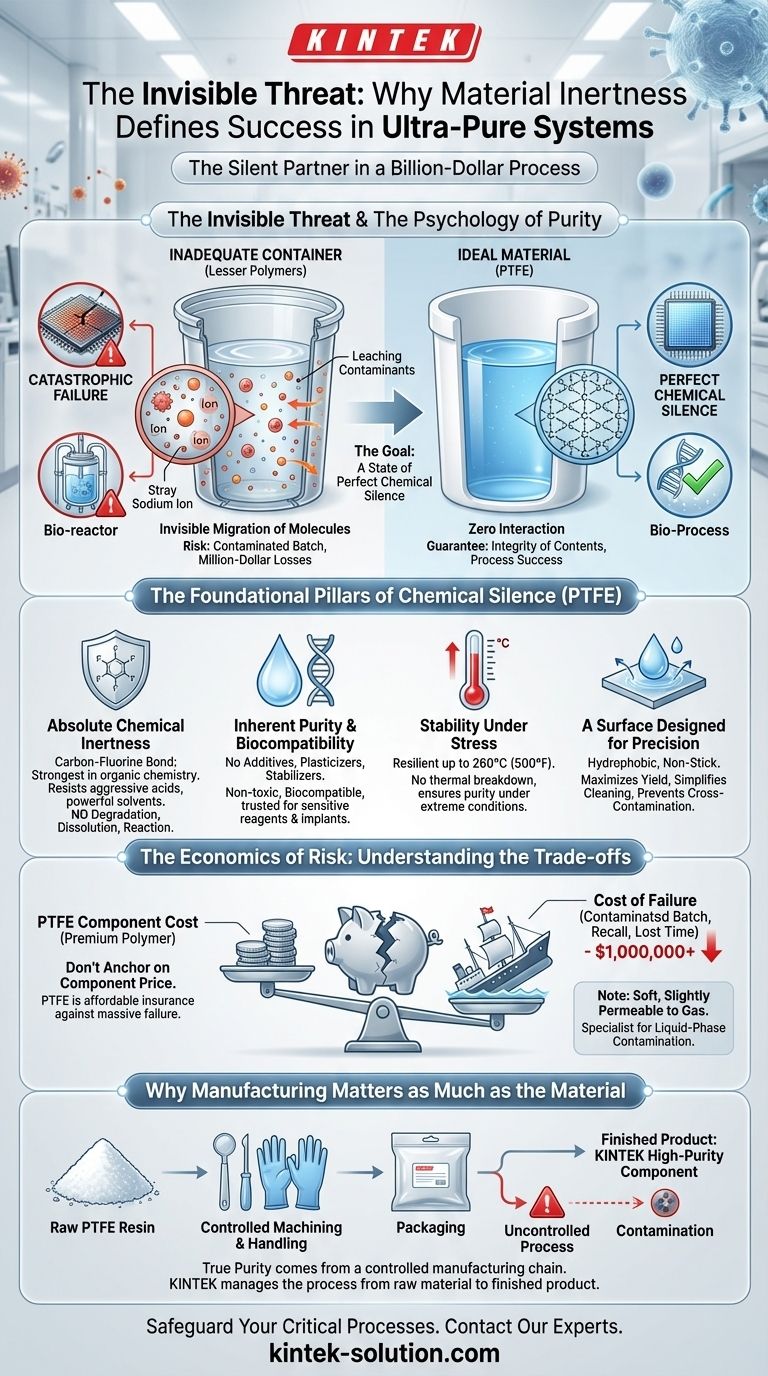

In a semiconductor cleanroom, the world is measured in nanometers and parts per billion. A single stray sodium ion, leached from an inadequate container holding a high-purity etchant, can render an entire wafer of microchips worthless. The financial loss isn't just the cost of the wafer; it's the cost of production time, diagnostics, and potentially millions in lost product.

The container holding the chemical isn't just a bottle; it's an active participant in the process. The question is whether its participation is benign or catastrophic.

In high-stakes environments, from fabricating CPUs to formulating life-saving biologics, the ideal material is a ghost: it must be present, but it must not interact. It must achieve a state of perfect chemical silence.

The Psychology of Purity: Trusting the Container

We are biased toward what we can see. We worry about visible dust or clumsy handling. Yet, the most insidious threat is invisible—the slow, silent migration of molecules from a container into its contents. This is called leaching.

Choosing a material for an ultra-pure application isn't just a technical decision; it's an act of trust. You are trusting that the container will not betray the integrity of what it holds.

This is where the unique molecular structure of Polytetrafluoroethylene (PTFE) becomes less a feature and more a guarantee. Its value is not in what it does, but in what it doesn't do.

The Foundational Pillars of Chemical Silence

PTFE's suitability for these demanding roles comes from a combination of properties that work in concert to eliminate variables and reduce risk.

1. Absolute Chemical Inertness

The carbon-fluorine bond is one of the strongest in organic chemistry. This is the source of PTFE’s legendary non-reactivity. It will not degrade, dissolve, or react with nearly any chemical, from aggressive acids to powerful solvents.

This isn't just about durability. It’s the fundamental reason it doesn't leach. The container remains itself, and the contents remain pure.

2. Inherent Purity & Biocompatibility

PTFE is inherently pure. It doesn't require additives, plasticizers, or stabilizers that could later become contaminants. Its non-toxic and biocompatible nature is so trusted that it's used for medical implants and bio-containment vessels.

This biological non-interference is a powerful indicator of its chemical purity. If it doesn't react with living tissue, it can be trusted with sensitive reagents.

3. Stability Under Stress

Purity must be maintained across a range of conditions. PTFE remains stable and inert up to 260°C (500°F). This thermal resilience ensures that heat won't trigger material breakdown, a common source of impurity release in lesser polymers.

4. A Surface Designed for Precision

The hydrophobic, non-stick surface of PTFE serves two critical functions:

- Maximizes Yield: It minimizes the amount of valuable sample that clings to the container walls, ensuring accurate transfers.

- Simplifies Cleaning: It can be cleaned thoroughly without harsh agents that might leave their own residue, reducing the risk of cross-contamination.

The Economics of Risk: Understanding the Trade-offs

No material is perfect for every context. Acknowledging PTFE's trade-offs is key to using it effectively.

The Cost of a Component vs. The Cost of Failure

PTFE is a premium polymer, and its cost is higher than materials like HDPE or polypropylene. This often leads to a cognitive error: anchoring on the component price.

The true financial calculation is not the cost of the PTFE bottle, seal, or liner. It is the cost of a contaminated batch, a failed experiment, or a product recall. A $100 precision-machined PTFE component is not expensive if it prevents a $1,000,000 failure. It’s the most affordable insurance you can buy.

Acknowledging Physical Boundaries

PTFE is a relatively soft material and is not ideal for high-impact structural roles. It is also slightly permeable to small gas molecules over long periods. It is a specialist, not a generalist. Its purpose is to provide the ultimate barrier against liquid-phase chemical contamination.

Why Manufacturing Matters as Much as the Material

The promise of PTFE's purity can be broken before it ever reaches your lab. The raw PTFE resin is only the starting point. The machining, handling, and packaging processes can introduce trace metals and particulates that defeat the entire purpose.

True purity comes from a controlled manufacturing chain.

| Property | Benefit for Ultra-Pure Applications | Potential Risk if Not Managed |

|---|---|---|

| Chemical Inertness | Resists virtually all chemicals; prevents leaching and contamination. | N/A (Inherent to material) |

| Inherent Purity | Non-toxic and biocompatible; safe for sensitive samples. | Contamination during fabrication |

| Thermal Stability | Stable up to 260°C (500°F) for high-temperature storage. | N/A (Inherent to material) |

| Hydrophobic Surface | Minimizes sample loss and allows for residue-free cleaning. | Surface damage from poor machining |

At KINTEK, we specialize in manufacturing high-purity PTFE components where process control is paramount. We understand that for our clients in the semiconductor, medical, and laboratory sectors, the component's history is as important as its material composition. By managing the process from raw material to finished product, we ensure the PTFE we deliver lives up to its promise of chemical silence.

Ensuring this level of purity requires more than just choosing the right polymer; it demands a partner who understands the intricacies of precision fabrication. To safeguard your critical processes, Contact Our Experts.

Visual Guide

Related Products

- Custom PTFE Bottles for Diverse Industrial Applications

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

- Custom PTFE Teflon Balls for Advanced Industrial Applications

Related Articles

- Beyond Sanitization: Why Your Material Choice Is the Real Key to Preventing Contamination

- The Real Reason You're Losing Samples: Why Your Choice of Lab Bottle Matters More Than You Think

- Beyond 'Non-Stick': The Physics and Psychology of Purity in PTFE Labware

- The Price of Purity: When a Simple Bottle Becomes Mission-Critical

- The Physics of Failure: Where Metal Fails, PTFE Prevails