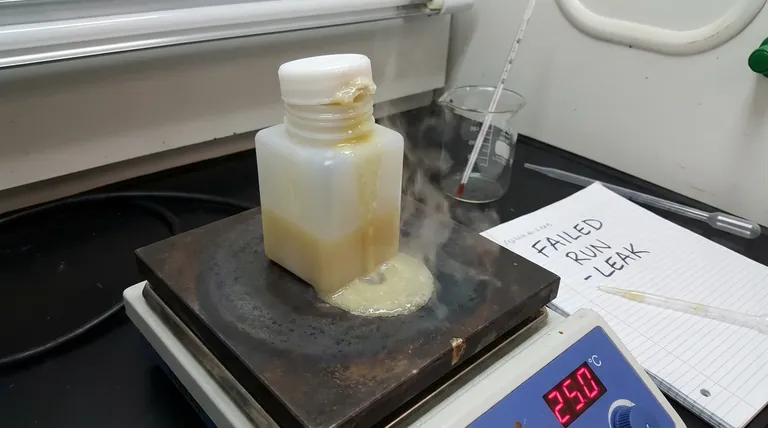

You’ve been here before. You pull a critical sample from the heating block or autoclave, only to find the container has leaked, or worse, your high-purity chemicals are now contaminated. You check the log: the temperature was set to 250°C. Your PTFE bottle is rated for 260°C. By all accounts, everything should have been perfect. Yet, here you are with a ruined experiment, wasted materials, and a timeline in jeopardy, asking the same frustrating question: "What went wrong?"

The Expensive Cycle of "Trying Again"

This isn't a freak accident; it's a chronic problem in labs and high-tech manufacturing facilities worldwide. When a high-temperature process fails, the typical response is a frustrating troubleshooting loop. We might:

- Blame the heating equipment and run lengthy calibration checks.

- Question the purity of the sample itself.

- "Play it safe" by running the next process at a much lower temperature, compromising efficiency.

- Discard a perfectly good PTFE bottle, assuming it has a hidden defect, and buy a more expensive one.

These attempts feel productive, but they rarely solve the underlying issue. The failures continue to happen, seemingly at random. The business consequences are anything but random. For a semiconductor fab, it means a scrapped batch of wafers, costing tens of thousands of dollars. For a medical lab, it means compromised samples and delayed clinical trials. For an R&D team, it means data you can't trust, undermining months of work and slowing down innovation.

The financial cost of wasted materials is significant, but the cost of lost time and eroded confidence is far greater.

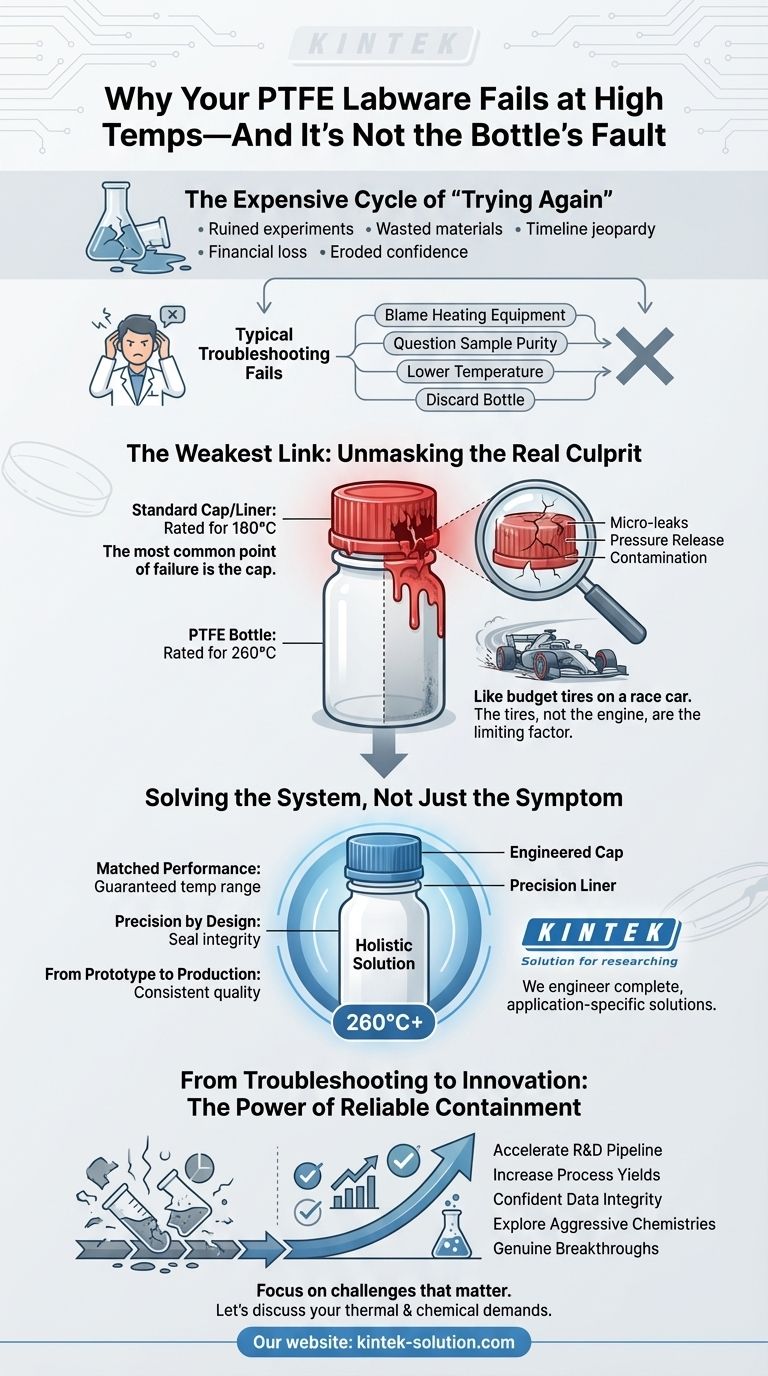

The Weakest Link: Unmasking the Real Culprit

The reason these attempts fail is simple: they focus on the wrong problem. In the vast majority of cases, the problem isn't your procedure, your heating block, or even the PTFE bottle.

The most common point of failure is the cap.

A high-performance system is only as strong as its weakest link. While a bottle made of pure PTFE can safely handle 260°C, the standard cap and liner assembly it ships with often cannot. Many standard caps, even those with PTFE liners, are only rated for continuous use up to 180°C.

When you heat the assembly to 250°C, the bottle performs flawlessly, but the cap assembly begins to soften, warp, or lose its sealing integrity. This leads to micro-leaks, pressure release, or direct contamination. It’s like equipping a race car with budget tires and being shocked when it can't handle a high-speed corner. The tires, not the engine, were the limiting factor.

This is why your troubleshooting fails. You’ve been trying to fix a world-class engine when the problem has always been the tires.

Solving the System, Not Just the Symptom

To guarantee process integrity at extreme temperatures, you don't just need a high-performance bottle. You need a holistically engineered containment system where every single component is rated for your specific application.

This is where an engineered approach becomes critical. A true solution requires ensuring the cap, the liner, and the bottle are all designed to work together under the exact thermal and chemical stresses of your process. This isn't about simply buying a product; it's about deploying a purpose-built tool.

At KINTEK, we specialize in exactly this. We don't just manufacture standard PTFE components; we engineer and fabricate complete, application-specific solutions.

- Matched Performance: We provide bottle and cap assemblies where every part is guaranteed to meet your required temperature range, whether it's 260°C for aggressive chemical processing or -200°C for cryogenic storage.

- Precision by Design: Our focus on precision manufacturing ensures that the seal integrity of your container is never the weak link that jeopardizes your work.

- From Prototype to Production: Whether you need a single, custom-designed unit for a groundbreaking experiment or thousands of units for a high-volume production line, we deliver the same level of guaranteed performance.

We build our components based on a deep understanding of the physics of failure, ensuring you get a system that works, not just a part that should.

From Troubleshooting to Innovation: The Power of Reliable Containment

Once you eliminate containment as a variable, you fundamentally change what's possible. Your team's valuable time shifts from debugging equipment to driving progress.

Instead of running validation tests, you can accelerate your R&D pipeline. Instead of worrying about wafer contamination, you can focus on increasing process yields. Instead of questioning data integrity, you can confidently explore more aggressive chemistries or higher process temperatures to unlock new levels of performance and discovery. This is how you move from incremental improvements to genuine breakthroughs.

Your work is too important to be sabotaged by a component as simple as a mismatched cap. It's time to stop troubleshooting symptoms and start solving the root problem. By ensuring your entire containment system is purpose-built for your needs, you can finally focus on the challenges that truly matter to your business. Let's discuss the specific thermal and chemical demands of your next project. Contact Our Experts.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Bottles for Diverse Industrial Applications

- Custom PTFE Teflon Parts Manufacturer Conductive Glass Substrate Cleaning Rack

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

Related Articles

- Why Your High-Performance PTFE Parts Fail—And Why It's Not the Material's Fault

- The Physics of a Perfect Fit: How PTFE Eliminates an Athlete's Hidden Distractions

- When "Chemically Inert" Isn't Enough: The Hidden Cause of PTFE Component Failure

- The Engineer's Dilemma: Navigating the Trade-offs Between PTFE and Its Alternatives

- The Asymmetric Cost of Failure: Why Precision PTFE Is Your Last Line of Defense