The Engineer's Dilemma: A Seemingly Perfect Machine

Imagine a pump in a chemical processing plant. It's a marvel of engineering—a powerful motor, a perfectly balanced impeller, and a housing made of corrosion-resistant stainless steel. Yet, every few months, it fails. The maintenance logs are a puzzle. The culprit isn't a catastrophic break, but a subtle, grinding seizure.

The problem isn't the major components. It's the tiny, unseen bushing where the drive shaft rotates.

In this chemically aggressive environment, traditional grease lubrication is a non-starter; it would react with the process fluids. A standard bronze bushing, durable in normal conditions, corrodes and binds. The failure isn't mechanical; it's environmental. The machine is fighting its surroundings, and losing.

This is a classic engineering blind spot: focusing on the strength of components while underestimating the hostility of the environment. The solution isn't a stronger metal, but a different philosophy of material science.

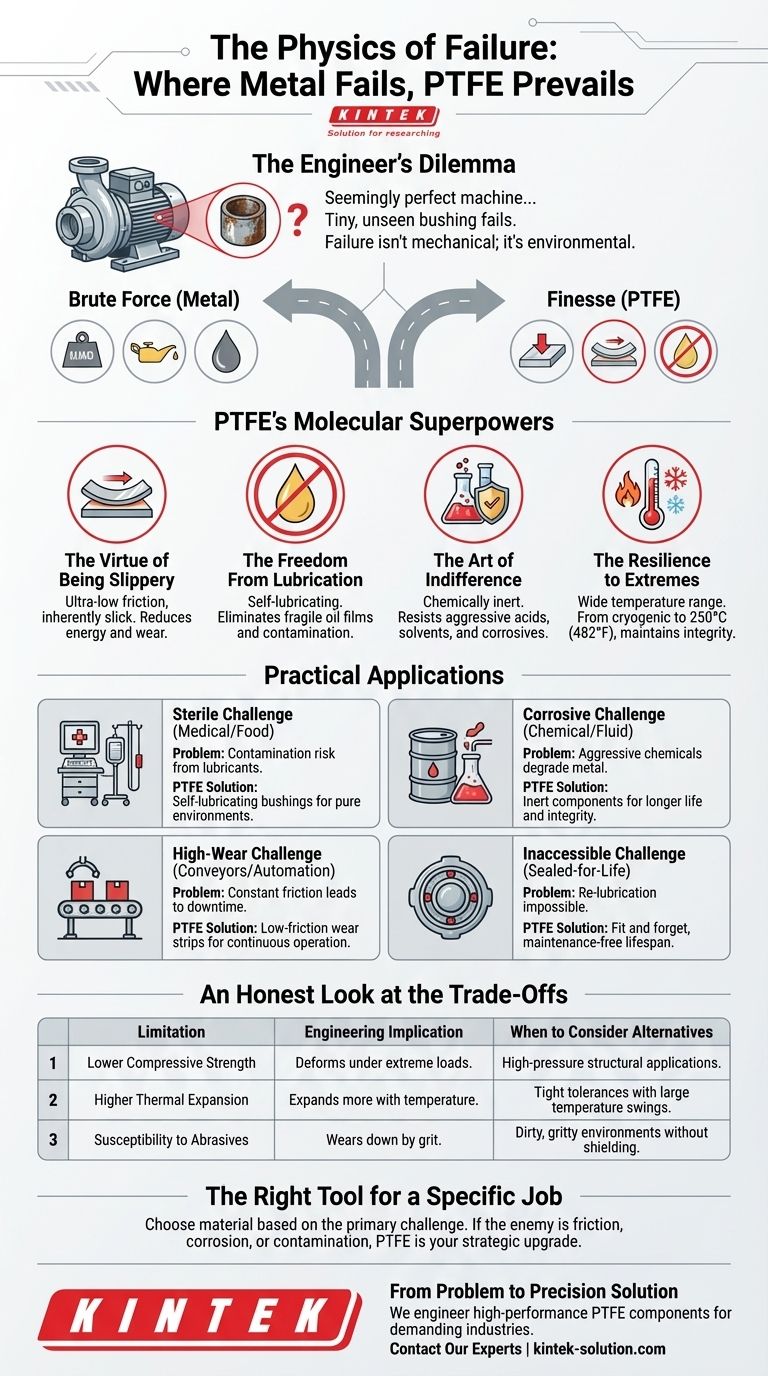

A Shift in Mindset: From Brute Force to Finesse

We are often biased toward materials that feel strong and substantial, like steel or bronze. It's an intuitive choice. But in many industrial applications, the primary challenge isn't withstanding immense force, but rather enduring a persistent, corrosive, or contamination-sensitive reality.

This is where Polytetrafluoroethylene (PTFE), commonly known as Teflon, demands a new way of thinking.

Choosing PTFE is less about replacing a part and more about redesigning the system's relationship with its environment. It's a strategic decision to solve problems that oil, grease, and hardened steel simply cannot.

The Molecular Superpowers of PTFE

PTFE's effectiveness isn't magic; it's a direct result of its unique molecular structure. Its properties make it a unique problem-solver.

The Virtue of Being Slippery

With one of the lowest coefficients of friction of any solid, PTFE is inherently slick. This isn't a coating; it's the nature of the material itself. This dramatically reduces the energy needed for movement, which means less wear, less heat, and higher efficiency.

The Freedom From Lubrication

Unlike metal bushings that depend on a fragile film of oil, PTFE is self-lubricating. This is a game-changer in applications where lubricants are impossible or undesirable. It eliminates a point of failure and a source of contamination.

The Art of Indifference

PTFE is chemically inert. It simply does not react with almost all industrial acids, solvents, and corrosive agents. Where even high-grade stainless steel would eventually pit and degrade, PTFE endures, making it the only viable choice for components directly handling aggressive fluids.

The Resilience to Extremes

From cryogenic temperatures to highs of 250°C (482°F), PTFE maintains its integrity. It won't become brittle in the cold or melt in the heat, allowing it to perform reliably in environments that would destroy lesser polymers or cause metals to seize.

Where the Environment Is the Enemy: Practical Applications

Grouping applications by the problem they solve reveals PTFE's true value.

The Sterile Challenge: Medical and Food Processing

- Problem: Any lubricant (oil, grease) is a potential contaminant. Sterility is paramount.

- PTFE Solution: Self-lubricating bushings and seals in medical devices, pharmaceutical mixers, and food processing equipment eliminate the need for external lubricants, ensuring a pure operational environment.

The Corrosive Challenge: Chemical and Fluid Handling

- Problem: Aggressive chemicals degrade metal components, leading to leaks, failure, and safety hazards.

- PTFE Solution: Bushings, seals, and liners in pumps and valves that handle acids and solvents. The material's chemical inertness guarantees a longer service life and system integrity.

The High-Wear Challenge: Conveyors and Automation

- Problem: Constant sliding motion in systems like conveyor belts and textile machinery creates friction and wear, leading to downtime.

- PTFE Solution: Wear strips and bushings provide a smooth, low-friction surface that allows for continuous operation with minimal maintenance, dramatically extending the life of the equipment.

The Inaccessible Challenge: Sealed-for-Life Components

- Problem: Some components are sealed or located in places where re-lubrication is impractical or impossible.

- PTFE Solution: A self-lubricating PTFE bushing is a "fit and forget" solution, ensuring reliable performance for the entire lifespan of the component without intervention.

An Honest Look at the Trade-Offs

No material is a universal solution. Understanding PTFE’s limitations is key to using it effectively.

| Limitation | Engineering Implication | When to Consider Alternatives |

|---|---|---|

| Lower Compressive Strength | Under extreme loads, PTFE can deform or "creep" over time where a metal part would not. | High-pressure bearings or structural load-bearing applications. |

| Higher Thermal Expansion | PTFE expands and contracts more than metal with temperature changes, requiring design clearance. | Applications with tight tolerances and extreme temperature swings. |

| Susceptibility to Abrasives | Abrasive particles like sand or grit can wear down the material faster than metal. | Dirty, dusty, or gritty environments without proper shielding. |

The Right Tool for a Specific Job

The choice of material should be dictated by the primary challenge.

- If the enemy is friction in a clean or hard-to-service area, PTFE is your solution.

- If the enemy is corrosion or contamination, PTFE is often the only viable choice.

- If the enemy is purely immense mechanical load, a specialized metal or composite bearing may be necessary.

By diagnosing the environment, not just the symptom, engineers can deploy PTFE as a strategic upgrade that enhances reliability and reduces long-term operational costs.

From Problem to Precision Solution

Understanding the power of PTFE is the first step. Translating that knowledge into a reliable, precision-manufactured component is the next. At KINTEK, we specialize in fabricating high-performance PTFE components—from seals and liners to custom bushings—for the most demanding industries, including semiconductor, medical, and industrial automation.

We don't just supply parts; we engineer solutions that solve the environmental challenges that cause lesser materials to fail. Whether you're developing a prototype or require high-volume production, our focus is on delivering the precise component that ensures your machinery's integrity and longevity.

Let's solve your specific challenge together. Contact Our Experts

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Square Trays for Industrial and Laboratory Use

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

Related Articles

- The Physics of a Perfect Fit: How PTFE Eliminates an Athlete's Hidden Distractions

- When "Chemically Inert" Isn't Enough: The Hidden Cause of PTFE Component Failure

- Why Your High-Performance PTFE Parts Fail—And Why It's Not the Material's Fault

- The Unseen Guardian: How PTFE's Molecular Shield Protects Our Most Critical Systems

- The PTFE Paradox: Why the 'Perfect' Material Fails—And How to Make It Work