You’re staring at a component spec sheet for a critical new product. You see two options for a bushing: one made with industry-standard PTFE, the other proudly labeled "PTFE-free."

A familiar knot of uncertainty tightens in your stomach. You've heard the growing concerns about "forever chemicals" (PFAS) and tightening environmental regulations. The last thing you need is a compliance headache or a PR nightmare down the line. But you also know PTFE's legendary performance—its low friction and chemical resistance are proven.

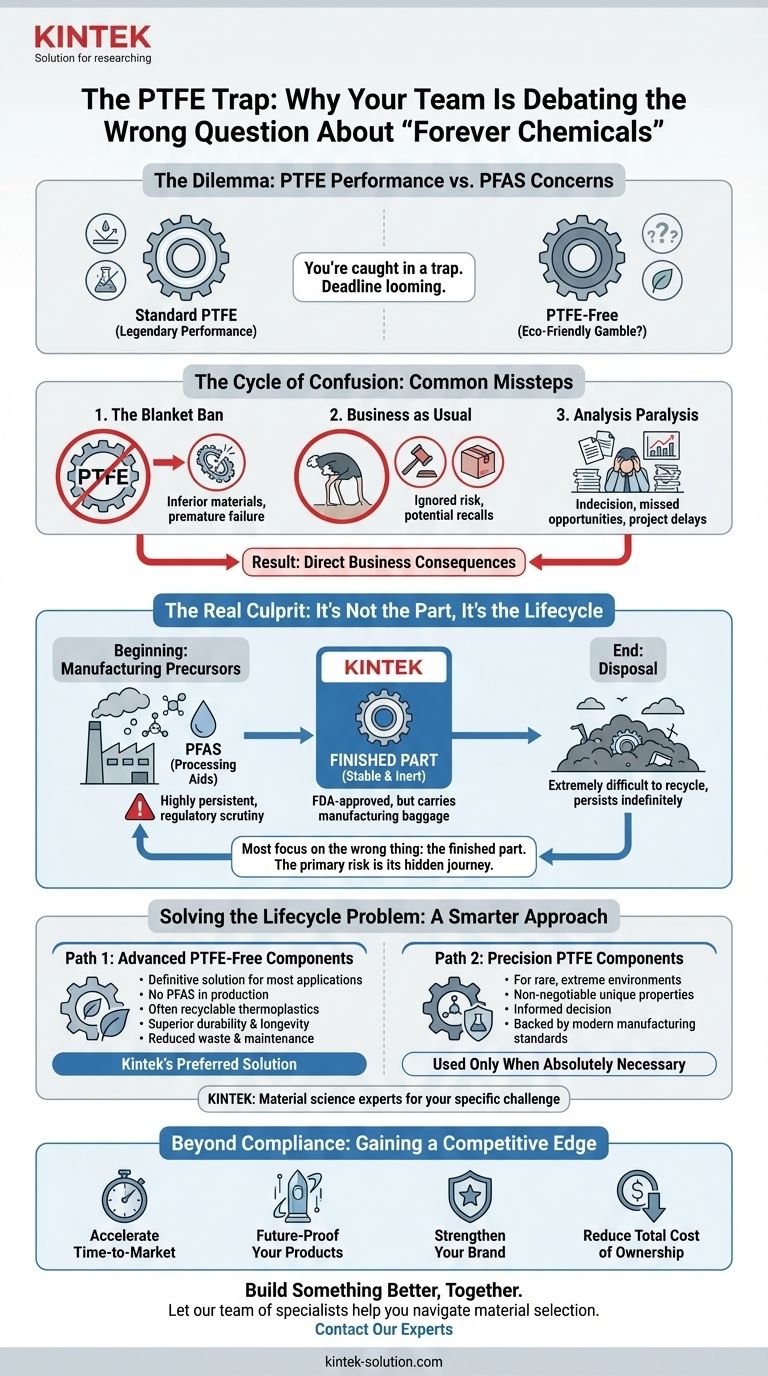

Choosing the "eco-friendly" option feels like a gamble on performance. Sticking with the tried-and-true PTFE feels like a regulatory risk. You're caught in a trap, and a project deadline is looming.

The Cycle of Confusion: Common Missteps and Hidden Costs

This exact scenario plays out in engineering departments and procurement offices every day. Faced with this dilemma, teams often fall into one of three unproductive patterns:

- The Blanket Ban: In an effort to be safe, some companies issue a top-down mandate to eliminate all PTFE. This can force engineers to use inferior materials, leading to premature component failure, increased warranty claims, and a damaged brand reputation.

- The "Business as Usual" Approach: Other teams ignore the noise, sticking with PTFE because "it's what we've always used." This strategy ignores a growing and significant business risk. As regulations around PFAS tighten, they expose their products to potential recalls, supply chain disruptions, and being designed out of a customer's next-generation system.

- Analysis Paralysis: The team spends weeks buried in conflicting data sheets, supplier claims, and dense technical articles, trying to become overnight experts on fluoropolymer chemistry.

This indecision isn't just academic; it has direct business consequences. Project timelines stretch, R&D costs balloon from testing unproven alternatives, and market opportunities are missed. The core problem is that the debate itself is framed incorrectly.

The Real Culprit: It’s Not the Part, It’s the Lifecycle

The reason this choice feels so impossible is that most people are focusing on the wrong thing. The confusion dissolves when you understand a simple but critical truth: the primary environmental risk of PTFE is not the finished part in your hand, but its hidden journey from creation to disposal.

The Problem at the Beginning: Manufacturing Precursors

In its final, solid form, PTFE is incredibly stable and inert. That's why it's FDA-approved for medical implants and cookware. The problem lies in its traditional manufacturing process, which historically used per- and polyfluoroalkyl substances (PFAS) as processing aids. These "forever chemicals" are highly persistent in the environment and are the source of the intense regulatory scrutiny. By choosing a component, you are implicitly choosing its manufacturing baggage.

The Problem at the End: Disposal

PTFE's incredible chemical stability is also its downfall at the end of its life. The material is extremely difficult and energy-intensive to recycle. In practice, most used PTFE components end up in landfills, where they will persist indefinitely.

The "common solutions" fail because they don't address this lifecycle reality. A blanket ban throws the baby out with the bathwater, sacrificing PTFE's unique performance when it might be necessary. Ignoring the issue simply kicks a very real and expensive can down the road.

Solving the Lifecycle Problem: A Smarter Approach to Material Selection

To escape the trap, you don't need to become a chemist. You need to shift your focus from a simple "PTFE vs. PTFE-free" choice to a smarter, application-specific material strategy. This requires a partner who understands the entire material lifecycle.

This is precisely why we've engineered our components the way we have. KINTEK is not just a parts supplier; we are material science experts dedicated to providing the right solution for your specific engineering challenge.

-

For the vast majority of applications, our advanced PTFE-free components are the definitive solution. They are specifically designed to eliminate the lifecycle problem. They require no PFAS in their production and are often made from thermoplastics that are more easily recycled. They aren't just an "eco-friendly" alternative; they are engineered for superior durability and longevity, reducing waste and maintenance cycles.

-

For the rare, extreme environments where PTFE's unique properties are non-negotiable, we provide precision-fabricated PTFE components. We help you make an informed decision, ensuring you use the right material only when absolutely necessary, backed by modern manufacturing standards.

Our expertise in custom fabrication, from a single prototype to high-volume production runs, means we can deliver a component that doesn't just fit your design, but also fits your environmental and regulatory strategy.

Beyond Compliance: Gaining a Competitive Edge with Smarter Materials

Once you are no longer stuck debating the wrong question, you unlock significant new potential. Solving the material selection dilemma is not just about avoiding risk; it's about creating a competitive advantage.

With a clear material strategy, you can:

- Accelerate Your Time-to-Market: End the decision paralysis and move confidently from design to production.

- Future-Proof Your Products: Design with materials that are ahead of the regulatory curve, avoiding costly redesigns and building trust with your customers.

- Strengthen Your Brand: Confidently market your products' superior performance and responsible design.

- Reduce Total Cost of Ownership: By using more durable components, you minimize replacements, downtime, and warranty costs for your end-users.

Your next project deserves more than a guess; it deserves a material strategy built on a deep understanding of performance and lifecycle impact. Let our team of specialists help you navigate the complexities of material selection, so you can focus on what you do best: building innovative and reliable products. Let's move beyond the confusion and build something better, together. Contact Our Experts

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

- Custom PTFE Volumetric Flasks for Advanced Scientific and Industrial Use

- Custom PTFE Square Trays for Industrial and Laboratory Use

Related Articles

- The PTFE Paradox: Why the 'Perfect' Material Fails—And How to Make It Work

- The Unseen Workhorse: Why PTFE Is the Default Choice for Impossible Problems

- The Physics of a Perfect Fit: How PTFE Eliminates an Athlete's Hidden Distractions

- Your "Inert" PTFE Component Might Be the Real Source of System Failure

- How PTFE Solves Critical Industrial Challenges Through Material Superiority