It’s a familiar, sinking feeling. You’ve run the analysis for a critical drug formulation—calibrating the instrument, meticulously preparing the sample, controlling every variable you can think of. Yet, as the chromatogram appears on screen, there it is: a strange, unexpected “ghost peak.” Or maybe your baseline is drifting, or your results from this morning don’t match yesterday’s. You’ve just lost another day, and you’re no closer to a reliable answer.

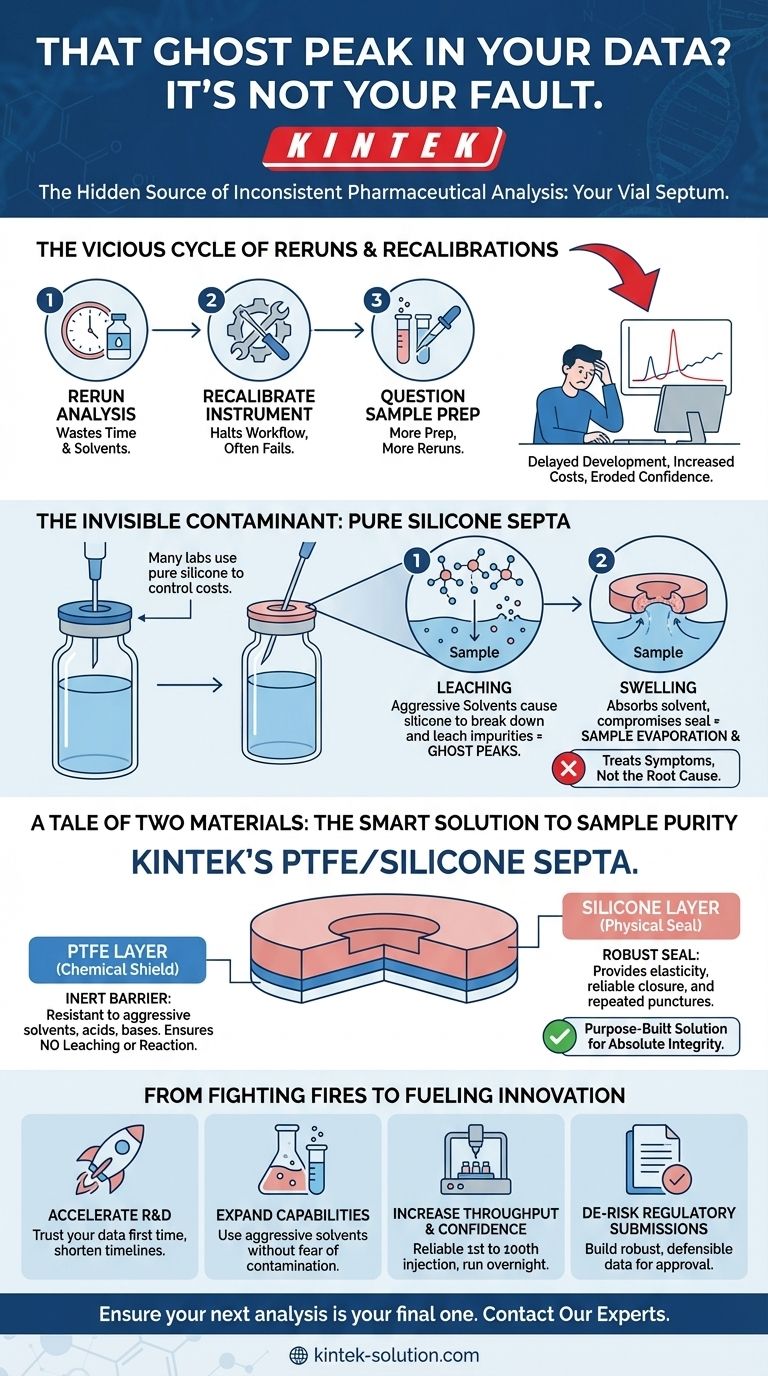

The Vicious Cycle of Reruns and Recalibrations

If this scenario sounds familiar, you’re not alone. Laboratories across the pharmaceutical industry are locked in a constant battle for reproducible data. When faced with inconsistent results, the typical response is a frustrating and costly process of elimination:

- Rerun the analysis: The most common first step, consuming valuable analyst time, expensive solvents, and other consumables.

- Recalibrate the instrument: This halts all other work on the machine, yet often fails to solve the underlying problem.

- Question the sample preparation: Was there an error in dilution? Was the solvent pure? This leads to more prep work and more reruns.

These efforts, while logical, often lead back to the same inconsistent results. The business consequences are severe. A single invalidated study can delay a drug’s development timeline by weeks or months. The cumulative cost of wasted materials and analyst hours drains R&D budgets. Most importantly, it erodes confidence in the data that underpins critical decisions about a drug’s safety and efficacy.

This frustrating cycle forces us to ask: are we missing a fundamental flaw?

The Invisible Contaminant: Why Your Vial Septum is Betraying Your Analysis

The problem often lies in a component so small it’s easily overlooked: the vial septum. It has two simple but critical jobs: create a leak-proof seal and do so without interacting with the sample inside.

Many labs, in an effort to control costs, use standard septa made of pure silicone. While silicone is excellent at creating a physical seal, it has a fatal flaw when it comes to sensitive pharmaceutical analysis: it is not chemically inert to many common organic solvents.

The Breakdown of a "Simple" Seal

When a pure silicone septum comes into contact with aggressive solvents used in chromatography (like acetonitrile, THF, or chlorinated solvents), two things happen:

- Leaching: The silicone begins to break down on a molecular level, "leaching" tiny impurities (silicone oligomers) directly into your sample. These contaminants then show up in your analysis as the "ghost peaks" that have no business being there.

- Swelling: The septum absorbs the solvent and swells, compromising the integrity of the seal. This can lead to sample evaporation, changing its concentration, and throwing off your quantitative results.

Recalibrating your instrument will never fix this. Rerunning the test with the same type of septum will only repeat the contamination. Your attempts to fix the problem were failing because you were treating the symptoms (bad data) instead of the disease (chemical reaction).

A Tale of Two Materials: The Smart Solution to Sample Purity

To permanently solve this problem, you don't just need a better seal; you need a smarter one. You need a material that can provide a perfect physical seal while remaining completely chemically non-reactive.

This is where a composite design becomes the only logical solution. The ideal septum combines two materials, each chosen for a specific job:

- The Chemical Shield: A thin layer of PTFE (polytetrafluoroethylene) faces the sample. PTFE is one of the most chemically inert materials known to science, resistant to virtually all acids, bases, and organic solvents. It forms an impenetrable barrier, ensuring absolutely nothing can leach into or react with your sample.

- The Physical Seal: A thicker body of high-quality silicone sits behind the PTFE. Its elasticity provides the robust, resealable seal needed for reliable vial closure and repeated punctures by autosampler needles.

The PTFE layer protects the silicone from the sample, and the silicone provides the mechanical integrity the PTFE lacks on its own. It's not a compromise; it's a purpose-built solution born from a deep understanding of the problem.

This is precisely why KINTEK specializes in manufacturing high-purity, precision PTFE components. We understand that in sensitive applications, material integrity isn't just a feature—it's the foundation of reliable results. Our PTFE seals and liners are not just parts; they are the embodiment of the solution to chemical contamination, ensuring that the only thing you measure is your sample.

From Fighting Fires to Fueling Innovation

Once you eliminate inconsistent data caused by chemical contamination, the entire dynamic of your lab changes. You stop wasting resources fighting preventable problems and start unlocking new potential.

- Accelerate R&D: Instead of spending weeks validating a single result, your team can move confidently to the next stage of discovery. You can trust your data the first time, dramatically shortening project timelines.

- Expand Your Capabilities: You can now use a wider range of aggressive solvents or develop novel analytical methods without fearing contamination, pushing the boundaries of your research.

- Increase Throughput and Confidence: Automated, high-throughput systems can run overnight without a second thought. The robust seal and chemical inertness of a PTFE-faced septum mean your 1st and 100th injections will be equally reliable.

- De-Risk Regulatory Submissions: You can build a dossier of robust, defensible data that stands up to scrutiny, smoothing the path to regulatory approval.

By addressing the root cause of data inconsistency with the right material, you transform a persistent technical headache into a powerful competitive advantage.

The integrity of your most critical research shouldn't be compromised by an overlooked component. If your work demands absolute sample purity and data you can trust, our team of material experts is here to help you find the right solution for your unique challenges. Let's ensure your next analysis is your final one. Contact Our Experts.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

- Custom PTFE Volumetric Flasks for Advanced Scientific and Industrial Use

- Customizable PTFE Seals Filter Holders for Versatile Applications

Related Articles

- The PTFE Paradox: Why the 'Perfect' Material Fails—And How to Make It Work

- The Physics of Trust: Why PTFE Is the Bedrock of High-Stakes Electronics

- The Physics of a Perfect Fit: How PTFE Eliminates an Athlete's Hidden Distractions

- Why Your High-Performance PTFE Parts Fail—And Why It's Not the Material's Fault

- The Unseen Workhorse: Why PTFE Is the Default Choice for Impossible Problems