To achieve tight tolerances in Teflon (PTFE) machining, you must use exceptionally sharp tools, implement meticulous thermal management with coolants, anneal the material to relieve stress, and use specialized fixtures that prevent deformation. These steps directly counteract PTFE's inherent softness, high thermal expansion, and tendency to creep under pressure, which are the primary obstacles to precision.

Success in machining PTFE is not about forcing the material into submission; it's about accommodating its unique properties. The core challenge is managing its extreme thermal expansion and softness, which requires a strategy focused on clean shearing, constant temperature control, and stress relief.

Understanding PTFE's Core Machining Challenges

Before applying best practices, it's essential to understand why PTFE is so difficult to machine. Its properties are fundamentally different from metals and most other plastics.

The Problem of Softness and Deformation

PTFE is extremely soft and has a low coefficient of friction. This means that dull tools will not cut it cleanly; they will push and deform the material, leading to poor surface finish and inaccurate dimensions.

Furthermore, standard clamping or workholding methods can easily crush or distort the workpiece, destroying any chance of achieving tight tolerances before the first cut is even made.

The Double-Edged Sword of Thermal Properties

PTFE has two thermal properties that create a significant challenge. First, its thermal expansion rate is very high—nearly ten times that of steel. Any heat generated during machining will cause the material to expand significantly.

Second, it has very low thermal conductivity. This means the heat generated by the cutting tool does not dissipate throughout the material. Instead, it concentrates at the cutting point, causing localized expansion and making precise measurements impossible until the part has completely cooled and stabilized.

The Impact of Internal Stress

The manufacturing process for raw PTFE stock induces internal stresses. During machining, as material is removed, these stresses are released unevenly, causing the part to warp and move in unpredictable ways. This makes holding tight tolerances on a finished part extremely difficult without proper stress relief.

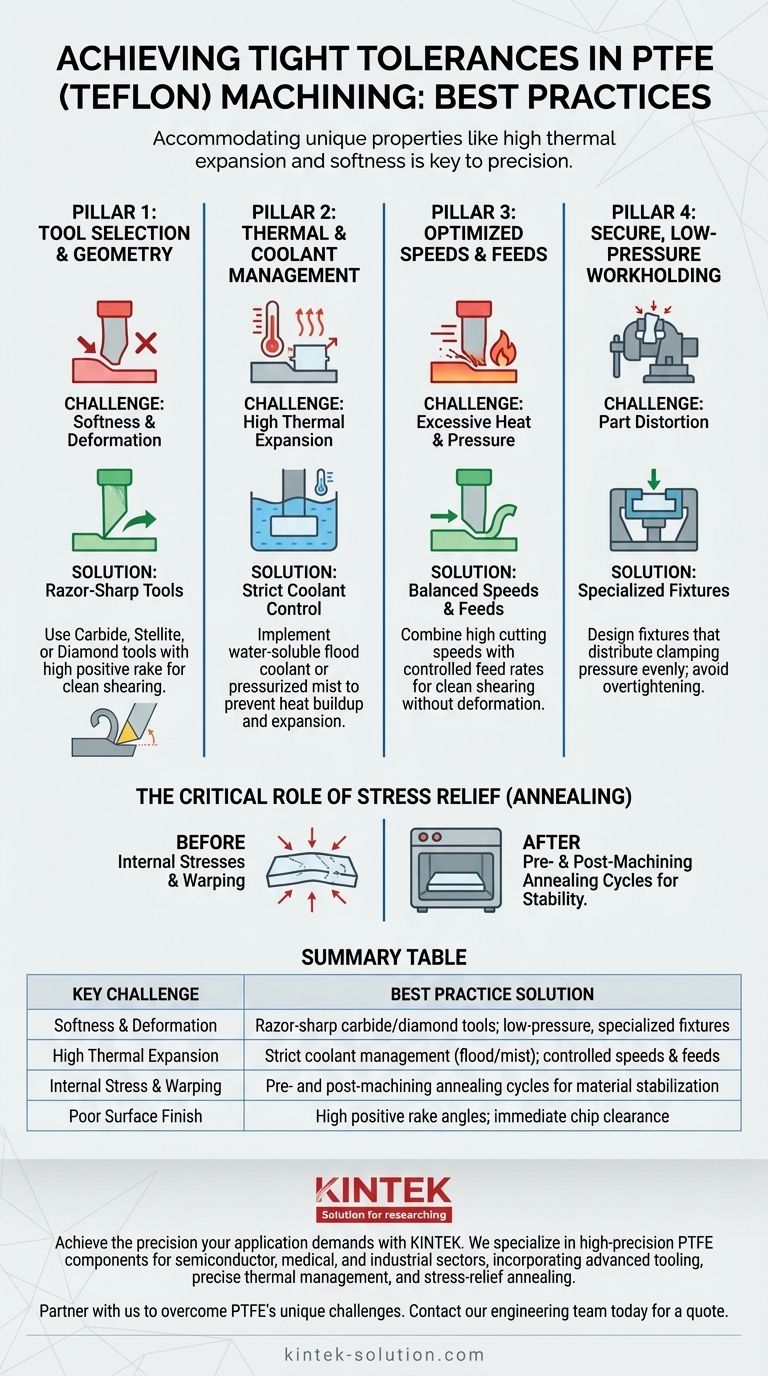

The Pillars of Precision PTFE Machining

A successful strategy for machining PTFE is built on a few core principles that directly address its challenging properties.

Pillar 1: Tool Selection and Geometry

The single most important factor is tool sharpness. Tools must be honed to a razor's edge to cleanly shear the material rather than pushing it.

Carbide, stellite-tipped, or even diamond tools are recommended due to their ability to hold a sharp edge. A high positive rake angle helps lift the chip away from the workpiece, reducing friction and heat buildup.

Pillar 2: Thermal and Coolant Management

Strict temperature control is non-negotiable. The goal is to remove heat as quickly as it's generated to prevent thermal expansion from affecting dimensional accuracy.

A water-soluble flood coolant is highly effective. Alternatively, pressurized air or misting systems can be used to manage heat and, just as importantly, clear away chips that could otherwise get caught and mar the soft surface.

Pillar 3: Optimized Speeds and Feeds

The general approach is to use high cutting speeds combined with controlled feed rates. High spindle speeds help ensure a clean shear, while a moderate feed rate prevents excessive tool pressure that could deform the part.

Finding the right balance is key to achieving a good surface finish without generating excessive heat.

Pillar 4: Secure, Low-Pressure Workholding

Fixtures must be designed specifically for PTFE. Use fixtures that support a large surface area of the part to distribute clamping pressure evenly.

Avoid overtightening vises or chucks. The goal is to hold the part securely enough to resist cutting forces but gently enough to avoid any distortion.

The Critical Role of Stress Relief (Annealing)

Annealing is the process of heating a material to a specific temperature and then slowly cooling it. For tight-tolerance PTFE parts, this is not an optional step.

Pre-Machining Annealing

Annealing the raw PTFE stock before machining is crucial for stabilizing the material. This process relieves the internal stresses from manufacturing, providing a more predictable and dimensionally stable workpiece to start with.

Post-Machining Annealing

After rough machining, a second annealing cycle can be performed to relieve stresses induced by the cutting process. This is particularly important for parts with complex geometries or extremely tight tolerances, as it ensures the final part will not warp or change dimensions over time.

Understanding the Trade-offs and Limitations

Even with perfect technique, it's vital to acknowledge the inherent limitations of the material.

Inherent Material Instability

Because of its high thermal expansion and tendency for stress creep (slow deformation under load), PTFE is not ideal for components that require absolute long-term dimensional stability compared to materials like steel or PEEK. Tolerances must be set realistically.

Lower Mechanical Strength

PTFE has relatively low tensile and compressive strength compared to other engineering polymers like nylon or Delrin. It is chosen for its lubricity and chemical resistance, not its mechanical fortitude.

Safety and Fume Production

A critical safety consideration is that PTFE produces toxic fumes when exposed to temperatures above 500°F (260°C). Machining processes must be controlled to ensure temperatures remain well below this threshold.

A Practical Checklist for Your Next PTFE Project

Use these guidelines to match your machining strategy to your primary objective.

- If your primary focus is ultimate precision and stability: You must incorporate both pre- and post-machining annealing cycles into your process.

- If your primary focus is an excellent surface finish: Prioritize exceptionally sharp tools with a high positive rake and use a consistent flood or mist coolant to clear chips immediately.

- If your primary focus is preventing part deformation: Design specialized, low-clamping-force fixtures and minimize tool pressure by using sharp tools and controlled feed rates.

Mastering these principles transforms PTFE from a challenging material into a predictable and reliable component for high-performance applications.

Summary Table:

| Key Challenge | Best Practice Solution |

|---|---|

| Softness & Deformation | Razor-sharp carbide/diamond tools; low-pressure, specialized fixtures |

| High Thermal Expansion | Strict coolant management (flood/mist); controlled speeds & feeds |

| Internal Stress & Warping | Pre- and post-machining annealing cycles for material stabilization |

| Poor Surface Finish | High positive rake angles; immediate chip clearance to prevent marring |

Achieve the precision your application demands with KINTEK.

Machining PTFE to tight tolerances requires specialized expertise and meticulous attention to detail—exactly what we deliver. At KINTEK, we manufacture high-precision PTFE components (seals, liners, labware, and more) for the semiconductor, medical, laboratory, and industrial sectors. Our process incorporates the critical best practices outlined here, including advanced tooling, precise thermal management, and stress-relief annealing, to ensure your parts meet exact specifications and perform reliably.

Whether you need prototypes or high-volume production, we partner with you to overcome the unique challenges of PTFE. Let's discuss your project requirements and how we can deliver the precision you need.

Contact our engineering team today for a quote

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Customizable PTFE Rods for Advanced Industrial Applications

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

People Also Ask

- What primary function does the PTFE Lined Spacer serve? Achieve Long-Term Reliability in Demanding Environments

- How does the shrinkage performance of PTFE gaskets affect their functionality? Ensure a Perfect, Leak-Free Seal

- What are the key advantages of PTFE coatings? Unlock Non-Stick, Chemical & Heat Resistance

- In which industries are PTFE ball valves commonly used? Essential for Chemical Resistance & Purity

- Why are PTFE rotary shaft seals suitable for food and beverage processing? Ensure Purity & Performance

- What other filler materials are used with PTFE besides fiberglass? A Guide to Carbon, Metal & Ceramic Fillers

- What are some unique features of expanded PTFE gaskets? Superior Conformability & Creep Resistance

- Why is low coefficient of friction particularly important in modern bridge design? It Prevents Destructive Stress from Thermal Expansion