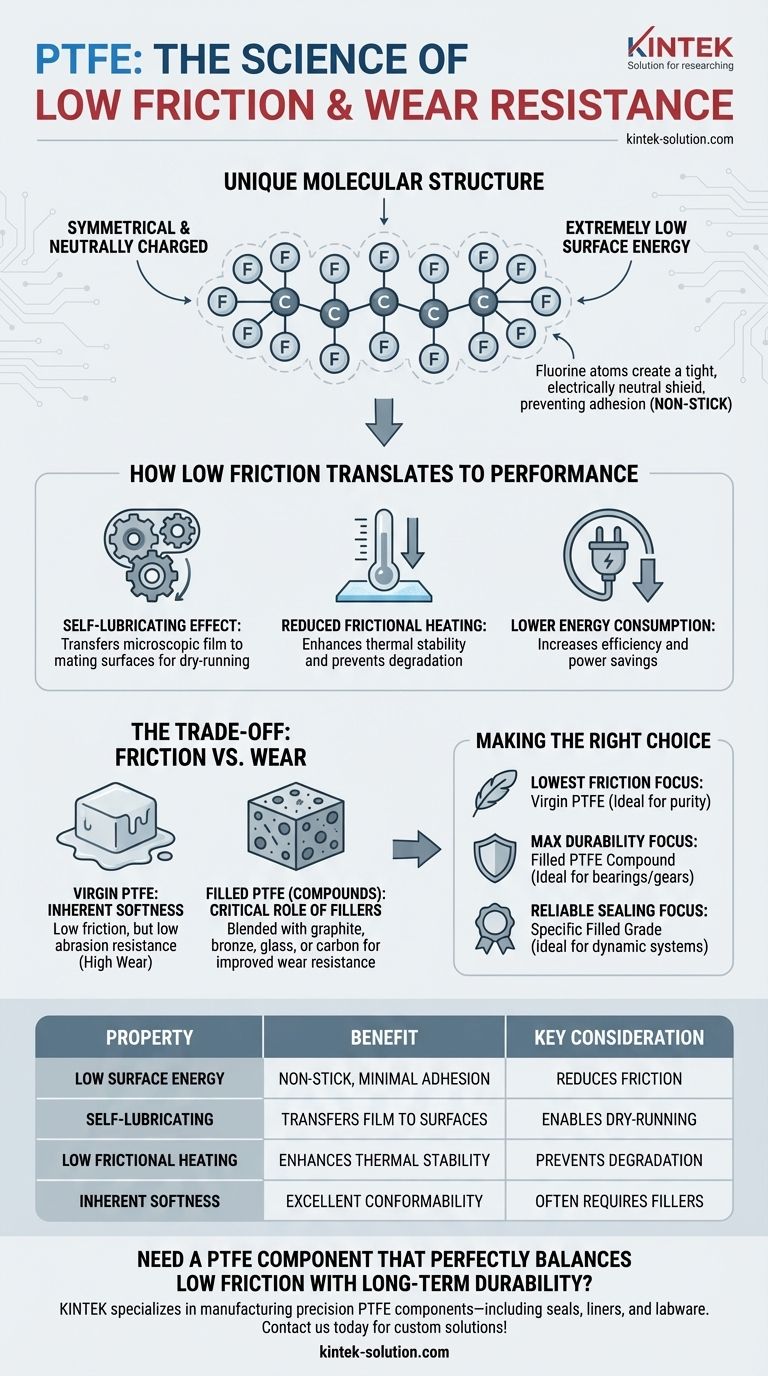

The fundamental reason PTFE exhibits extremely low friction is its unique molecular structure. The fluorine atoms create a tight, electrically neutral shield around the carbon backbone, resulting in a very low surface energy that prevents other materials from effectively adhering to it. This "non-stick" quality is complemented by its self-lubricating nature, where it transfers a microscopic film to mating surfaces.

PTFE’s low friction is not just a surface-level quality; it is a direct result of its electrically neutral molecular structure. This creates a non-stick, self-lubricating effect that minimizes both adhesion and frictional heating in moving parts, but its inherent softness often requires reinforcement for high-wear applications.

The Foundation: A Unique Molecular Structure

To understand PTFE's performance, we must first look at its chemical composition. The properties that make it a superior material for low-friction applications are born at the molecular level.

Symmetrical and Electrically Neutral

The PTFE molecule consists of a long chain of carbon atoms completely surrounded by fluorine atoms.

This symmetrical arrangement of fluorine atoms effectively cancels out any local electrical charges (dipole moments) along the chain.

The result is a molecule that is electrically neutral and non-polar, which dramatically reduces the intermolecular forces of attraction (van der Waals forces) between PTFE and other surfaces.

Extremely Low Surface Energy

This lack of electrical attraction gives PTFE an incredibly low surface energy.

Think of it like a surface that nothing can chemically "grip." This is the core principle behind its famous non-stick properties, which directly translates to a very low coefficient of friction.

How Low Friction Translates to Performance

The molecular advantage of PTFE creates tangible benefits in mechanical systems, primarily through its ability to manage friction and wear without external help.

The Self-Lubricating Effect

In applications with moving parts, PTFE deposits a very thin film of its own material onto the mating surface.

This "transfer film" means the PTFE component is effectively sliding against another layer of PTFE, not the original metal or plastic surface. This process is the essence of its self-lubricating capability.

This allows PTFE components, like seals and bearings, to perform exceptionally well even in dry-running conditions where external lubricants are absent.

Reduced Frictional Heating

In dynamic applications, high friction generates heat, which can cause materials to degrade and fail prematurely.

PTFE’s very low coefficient of friction minimizes this heat generation. This thermal stability is critical for maintaining performance and integrity in high-speed rotating or sliding parts.

Lower Energy Consumption

By reducing the resistive force of friction, PTFE helps systems operate more efficiently.

In machinery with many moving parts, this can lead to significant power savings and a longer operational service life for the entire assembly.

Understanding the Trade-offs: Friction vs. Wear

While its low friction is a major advantage, it's critical to understand that this property does not automatically equate to high durability under all conditions.

PTFE's Inherent Softness

In its pure, or "virgin," state, PTFE is a relatively soft material.

While it has a low tendency to cause friction, its own abrasion resistance can be low. In applications with high mechanical loads or abrasive media, virgin PTFE can wear down quickly.

The Critical Role of Fillers

To overcome this limitation, PTFE is often blended with fillers to create composite materials, or compounds.

Adding materials like graphite, bronze, glass, or carbon dramatically improves wear resistance, creep resistance, and overall mechanical strength. These fillers create a composite that maintains low friction while offering the durability required for demanding applications.

Making the Right Choice for Your Goal

Selecting the correct form of PTFE depends entirely on the primary demands of your application.

- If your primary focus is achieving the absolute lowest coefficient of friction: Virgin (unfilled) PTFE is the ideal choice, especially in applications where material purity is critical.

- If your primary focus is maximizing durability and service life: A filled PTFE compound (e.g., with bronze or carbon) is necessary to provide the required wear and load resistance for parts like bearings and gears.

- If your primary focus is reliable sealing in a dynamic system: The self-lubricating and heat-reducing properties of PTFE are paramount, and a specific filled grade is often chosen to balance low friction with long-term wear resistance.

Ultimately, understanding this interplay between PTFE's inherent lubricity and the strength added by fillers is the key to engineering highly efficient and durable systems.

Summary Table:

| Property | Benefit | Key Consideration |

|---|---|---|

| Low Surface Energy | Non-stick, minimal adhesion | Reduces friction and power consumption |

| Self-Lubricating | Transfers film to mating surfaces | Enables dry-running operation |

| Low Frictional Heating | Enhances thermal stability | Prevents material degradation |

| Inherent Softness | Excellent conformability | Often requires fillers for wear resistance |

Need a PTFE component that perfectly balances low friction with long-term durability?

KINTEK specializes in manufacturing precision PTFE components—including seals, liners, and labware—for the semiconductor, medical, laboratory, and industrial sectors. We offer custom fabrication from prototypes to high-volume orders, ensuring your parts meet exact performance requirements.

Contact us today to discuss how our PTFE solutions can enhance your system's efficiency and reliability.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Square Trays for Industrial and Laboratory Use

- Customizable PTFE Rods for Advanced Industrial Applications

- Custom PTFE Volumetric Flasks for Advanced Scientific and Industrial Use

People Also Ask

- Why is CNC machining preferred for Teflon parts over other methods? Unlock Precision & Complex Designs

- What tips can improve Teflon machining results? Master Sharp Tools, Heat Control, and Rigid Support

- What are the future considerations for machining Teflon? Mastering Material Challenges with Smart Tech

- What are the key considerations when machining Teflon? Master Precision Machining for Soft Polymers

- Why is PTFE rod suitable for automotive applications? Boost Vehicle Performance & Durability