Machining Teflon (PTFE) requires a unique approach that prioritizes finesse over force. The primary considerations revolve around managing the material's inherent softness, its extremely high rate of thermal expansion, and its tendency to deform under pressure, all of which pose significant challenges to achieving tight tolerances and a clean surface finish.

The core challenge of machining Teflon is not cutting it, but controlling it. Success depends entirely on minimizing heat generation and mechanical stress through specialized tooling, proper workholding, and carefully controlled parameters.

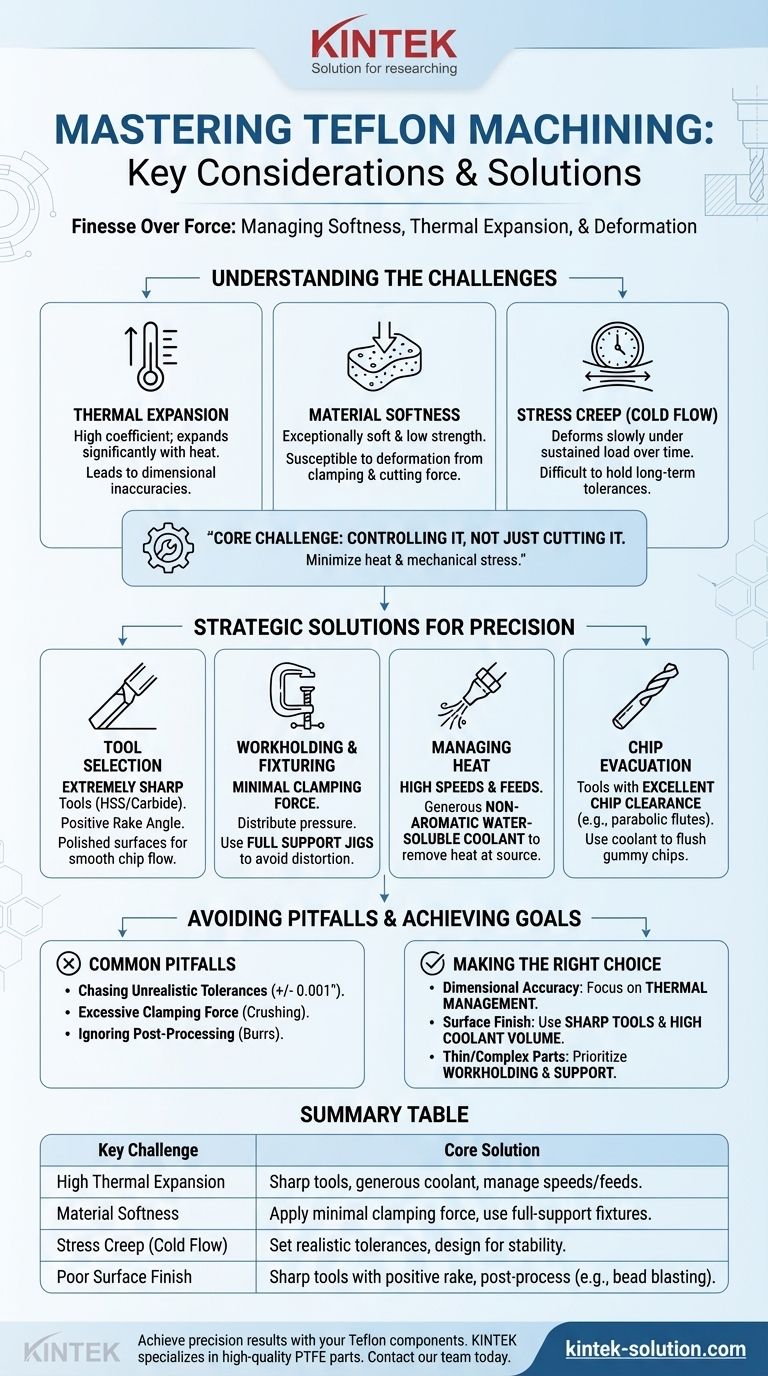

Understanding Teflon's Core Challenges

To machine Teflon effectively, you must first understand the properties that make it so distinct from metals or even other plastics. These properties are the root cause of every common machining issue.

The Problem of Thermal Expansion

Teflon has a very high coefficient of thermal expansion. This means it expands and contracts significantly with even minor changes in temperature.

Heat generated from the friction of a cutting tool can cause the material to expand mid-process, leading to inaccurate dimensions once the part cools down. Maintaining a stable temperature is critical for holding any meaningful tolerance.

The Impact of Material Softness

Teflon is an exceptionally soft material with low strength. While this makes it easy to cut, it also makes it highly susceptible to deformation.

Excessive clamping pressure can crush or distort the workpiece before you even begin machining. The force of the cutting tool itself can push the material away rather than shearing it cleanly, resulting in tool chatter, poor surface finishes, and inaccurate cuts.

The Challenge of Stress Creep (Cold Flow)

Teflon is known to "creep" or deform slowly over time when under a sustained load.

This means that even if a part is machined to a perfect tolerance, internal stresses or pressure from its application can cause its dimensions to change over time. This property makes holding long-term, high-precision tolerances particularly difficult.

Strategic Solutions for Precision Machining

Overcoming Teflon's challenges requires a strategy focused on mitigating heat and pressure. Every choice, from the tool to the coolant, must serve this goal.

Tool Selection is Non-Negotiable

The single most important factor is using the right tool. The goal is to slice the material cleanly, not plow through it.

Your tools must be extremely sharp. High-speed steel (HSS) or cemented carbide tools are recommended. Dull tools will create excess friction, heat, and deformation. Tools should also have a positive rake angle and polished surfaces to promote smooth chip flow and reduce friction.

Workholding and Fixturing

Because Teflon is both soft and slippery, securing it is a delicate balance.

Use minimal clamping force distributed over a large surface area to avoid distorting the part. Full support jigs or fixtures that conform to the part's shape are ideal for preventing deformation during the machining process.

Managing Heat with Speeds, Feeds, and Coolant

Controlling temperature is paramount. This is achieved through a combination of machine parameters and cooling.

Use high cutting speeds and feed rates with an extremely sharp tool to ensure the tool is shearing the material efficiently. A generous application of a non-aromatic, water-soluble coolant is highly effective at removing heat at the source, preventing thermal expansion and improving surface finish.

Chip Evacuation

Teflon produces long, gummy chips that can clog tooling, increase friction, and ruin the part.

Select tools designed for excellent chip clearance, such as drills with parabolic flutes. Proper coolant application can also help flush chips away from the cutting zone.

Common Pitfalls to Avoid

Many common machining practices are counterproductive when working with Teflon. Awareness of these pitfalls is key to preventing scrapped parts.

Chasing Unrealistic Tolerances

Understand that Teflon is not a dimensionally stable material like aluminum or steel. Its tendency to expand and creep makes holding tolerances tighter than +/- 0.001 inches extremely challenging. Be realistic about what the material can achieve.

Applying Excessive Clamping Force

This is the most common mistake. Operators accustomed to machining metals often over-tighten fixtures, crushing the Teflon workpiece and making accurate machining impossible from the start. Always begin with the lightest possible clamping pressure.

Ignoring Post-Processing Needs

Due to its softness, a machined surface on Teflon can have a "fluffy" or burred texture. A post-processing step like bead blasting is often necessary to achieve a smooth, uniform surface finish.

Making the Right Choice for Your Goal

Your specific objective should guide your machining strategy.

- If your primary focus is dimensional accuracy: Prioritize thermal management above all else, using sharp tools, generous coolant, and allowing the material to stabilize at room temperature before final measurements.

- If your primary focus is surface finish: Use extremely sharp tools with polished flutes and a constant, high-volume flow of water-soluble coolant to prevent any rubbing or heat buildup.

- If you are machining thin-walled or complex parts: Concentrate on workholding, designing fixtures that provide full support to the part and using the absolute minimum clamping pressure required.

By respecting the material's unique properties, you can transform Teflon machining from a challenge into a repeatable, precise process.

Summary Table:

| Key Challenge | Core Solution |

|---|---|

| High Thermal Expansion | Use sharp tools, generous coolant, and manage speeds/feeds. |

| Material Softness | Apply minimal clamping force and use full-support fixtures. |

| Stress Creep (Cold Flow) | Set realistic tolerances and design for long-term stability. |

| Poor Surface Finish | Employ sharp tools with positive rake angles and post-process (e.g., bead blasting). |

Achieve precision results with your Teflon components. KINTEK specializes in machining high-quality PTFE parts like seals, liners, and custom labware for the semiconductor, medical, and industrial sectors. Our expertise in managing material softness and thermal expansion ensures your prototypes or high-volume orders meet exact specifications. Contact our team today to discuss your project and benefit from our custom fabrication capabilities.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Customizable PTFE Rods for Advanced Industrial Applications

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

People Also Ask

- What tips can improve Teflon machining results? Master Sharp Tools, Heat Control, and Rigid Support

- How does PTFE contribute to low friction and wear resistance? Achieve Superior Performance with Advanced Materials

- What are the main advantages of using PTFE parts in industrial applications? Unlock Unmatched Chemical Resistance and Reliability

- Why is PTFE rod suitable for automotive applications? Boost Vehicle Performance & Durability

- What are the key advantages of PTFE? Unmatched Performance for Extreme Environments