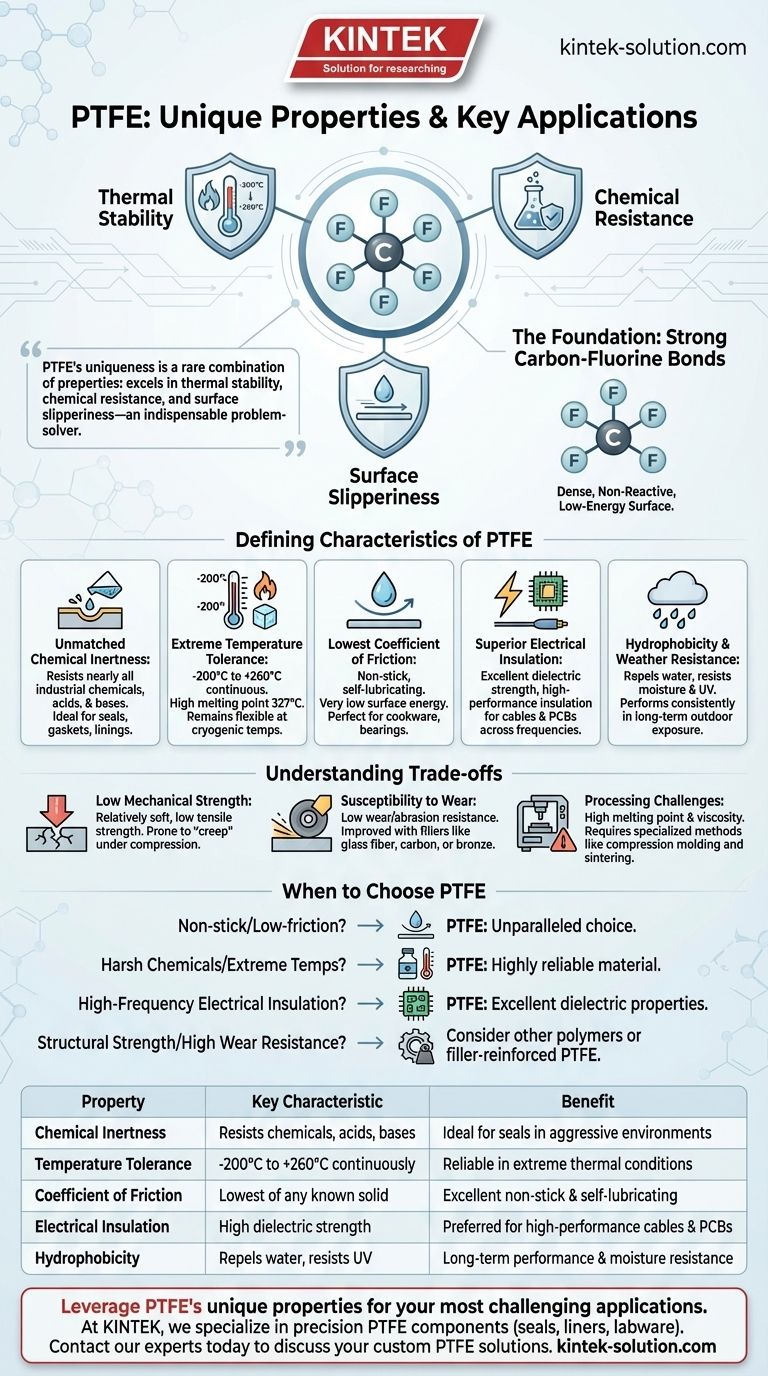

The unique properties of Polytetrafluoroethylene (PTFE) stem from its exceptionally strong carbon-fluorine bonds. This stable molecular structure is directly responsible for its most famous characteristics: an extremely low coefficient of friction (making it exceptionally non-stick), near-total chemical inertness, and remarkable resistance to a wide range of temperatures.

At its core, PTFE's uniqueness isn't just one property but a rare combination of them. It simultaneously excels in thermal stability, chemical resistance, and surface slipperiness—a trifecta that makes it an indispensable problem-solver in industries from aerospace to medicine.

The Foundation of PTFE's Properties

The Carbon-Fluorine Bond

The defining features of PTFE originate at the molecular level. The polymer consists of a long chain of carbon atoms completely shielded by a sheath of fluorine atoms.

These carbon-fluorine bonds are incredibly strong and stable. This structure creates a molecule that is dense, non-reactive, and presents a very low-energy surface to the outside world.

The Defining Characteristics of PTFE

Unmatched Chemical Inertness

Because of its stable molecular structure, PTFE is one of the most non-reactive substances known. It can withstand exposure to nearly all industrial chemicals, acids, and bases.

This property makes it an ideal material for seals, gaskets, and linings used in chemically aggressive environments.

Extreme Temperature Tolerance

PTFE performs reliably across an exceptionally broad temperature spectrum. It remains flexible at cryogenic temperatures as low as -200°C and can be used continuously at temperatures up to +260°C (500°F).

It has a very high melting point of 327°C, far exceeding that of most other polymers.

The Lowest Coefficient of Friction

PTFE has the lowest coefficient of friction of any known solid material. This gives it its famous non-stick or "self-lubricating" quality.

This extremely low surface energy means that very few materials will adhere to it, a critical property for applications ranging from non-stick cookware to low-friction bearings.

Superior Electrical Insulation

PTFE is an excellent electrical insulator with very high dielectric strength. It maintains its insulating properties across a wide range of frequencies and temperatures.

This makes it a preferred material for high-performance applications, such as insulation for cables and components in printed circuit boards (PCBs).

Hydrophobicity and Weather Resistance

PTFE is hydrophobic, meaning it repels water and is resistant to moisture absorption.

It also exhibits outstanding resistance to weathering and degradation from UV radiation, allowing it to perform consistently during long-term outdoor exposure.

Understanding the Trade-offs

Low Mechanical Strength

While durable and flexible, pure PTFE is a relatively soft material with low tensile strength. It is not suitable for load-bearing or structural applications on its own.

Under compression, it can be susceptible to "creep" or cold flow over time.

Susceptibility to Wear

Contrary to some claims, pure PTFE has relatively low wear and abrasion resistance due to its softness. Its mechanical properties, including wear resistance, are often significantly improved by adding fillers like glass fiber, carbon, or bronze.

Processing Challenges

PTFE's high melting point and high melt viscosity make it difficult to process using conventional melt-processing techniques like injection molding. It typically requires specialized methods like compression molding and sintering.

When to Choose PTFE

Leveraging PTFE effectively requires matching its unique profile to the right application.

- If your primary focus is a non-stick, low-friction surface: PTFE is the unparalleled choice, offering the lowest coefficient of friction of any solid material.

- If your primary focus is resistance to harsh chemicals or extreme temperatures: PTFE's inertness and wide operating range make it a highly reliable material for seals, gaskets, and linings.

- If your primary focus is high-frequency electrical insulation: Its excellent dielectric properties are ideal for demanding applications in cables and circuit boards.

- If your primary focus is structural strength or high wear resistance: You should consider a different polymer or a specifically engineered, filler-reinforced grade of PTFE.

Ultimately, understanding both PTFE's remarkable strengths and its inherent limitations is the key to applying it successfully.

Summary Table:

| Property | Key Characteristic | Benefit |

|---|---|---|

| Chemical Inertness | Resists nearly all industrial chemicals, acids, and bases. | Ideal for seals and linings in aggressive environments. |

| Temperature Tolerance | Performs from -200°C to +260°C continuously. | Reliable in extreme thermal conditions. |

| Coefficient of Friction | Lowest of any known solid material. | Excellent non-stick and self-lubricating properties. |

| Electrical Insulation | High dielectric strength across frequencies and temperatures. | Preferred for high-performance cables and PCBs. |

| Hydrophobicity | Repels water and resists UV/weathering. | Long-term performance and moisture resistance. |

Leverage PTFE's unique properties for your most challenging applications.

At KINTEK, we specialize in the precision manufacturing of high-performance PTFE components—including custom seals, liners, and labware—for the semiconductor, medical, laboratory, and industrial sectors. Whether you need a prototype or a high-volume production run, our expertise ensures you get components that deliver on PTFE's full potential.

Contact our experts today to discuss how our custom PTFE solutions can solve your specific design challenges.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

- Customizable PTFE Rods for Advanced Industrial Applications

- Custom PTFE Volumetric Flasks for Advanced Scientific and Industrial Use

People Also Ask

- Why is PTFE suitable for cryogenic or high-temperature applications? Unmatched Thermal Stability from -450°F to 500°F

- What are the best practices for achieving tight tolerances in Teflon (PTFE) machining? Master Precision for Demanding Applications

- What are the primary applications of PTFE fasteners and custom parts? Critical Solutions for Extreme Environments

- What are the base characteristics of PTFE? Unlocking Extreme Performance in Friction, Temperature, and Chemical Resistance

- What are the material advantages of machining Teflon? Unlock Unmatched Chemical & Thermal Resistance