At its core, the material advantage of machining Teflon, or PTFE, lies in its unique combination of extreme resilience and inherent machinability. Its properties make it a premier choice for high-performance components that must function in environments where other materials would quickly fail due to chemical attack, temperature extremes, or friction.

Teflon is not chosen for its strength, but for its survivability. Its primary advantages are an almost universal chemical inertness, an exceptionally wide operating temperature range, and one of the lowest coefficients of friction of any solid, making it a problem-solver for the most demanding applications.

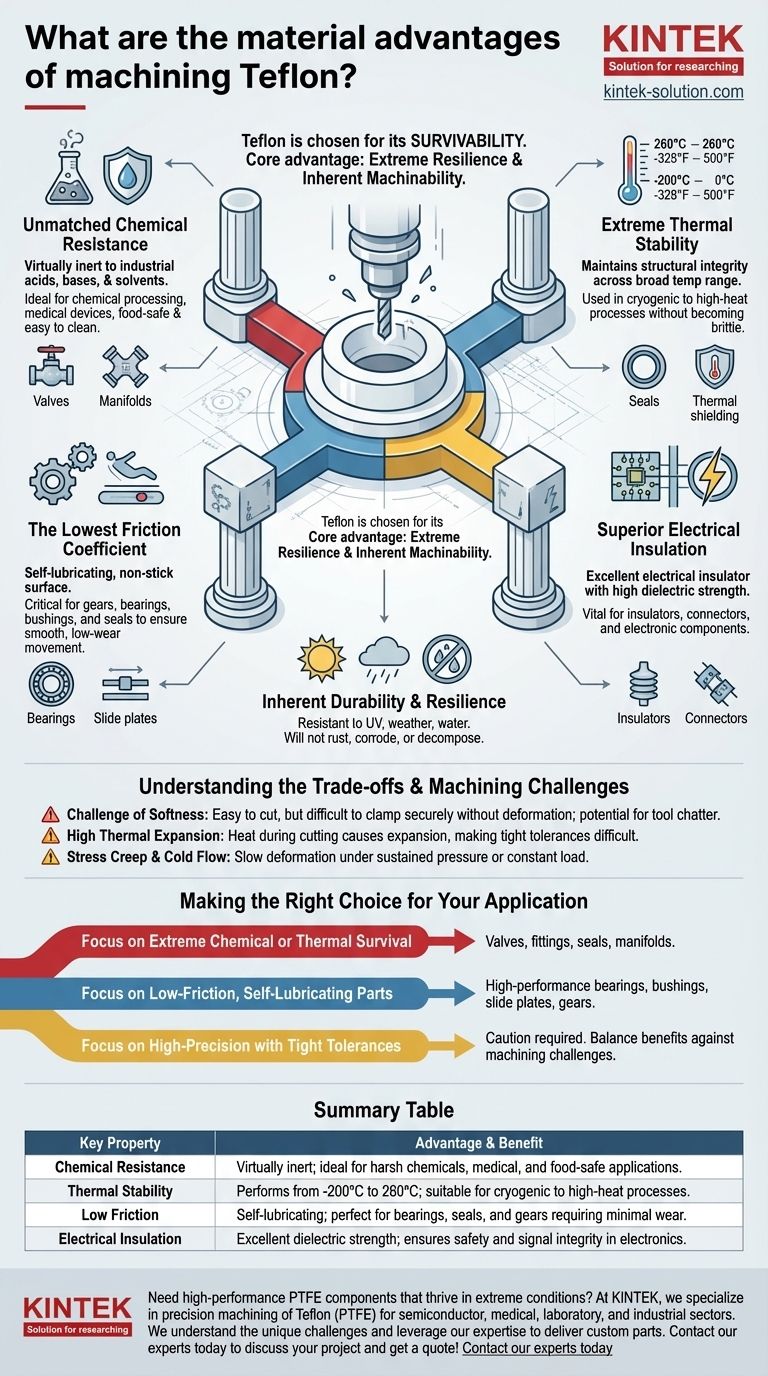

The Pillars of Teflon's Performance

The reasons for specifying Teflon almost always trace back to one of four key material characteristics. These properties work in concert to deliver reliable performance under severe operating conditions.

Unmatched Chemical Resistance

Teflon is virtually inert and does not react with the vast majority of industrial acids, bases, and solvents. This makes it an ideal material for components in chemical processing, medical devices, and food production.

Because of this inertness, it is considered food-safe and is exceptionally easy to clean, as very few substances will adhere to its surface.

Extreme Thermal Stability

Teflon maintains its structural integrity and performance across an exceptionally broad temperature range, typically from -200°C to 260°C (-328°F to 500°F).

This stability allows it to be used in everything from cryogenic applications to high-temperature industrial processes without becoming brittle or deforming.

The Lowest Friction Coefficient

Known for its slippery, non-stick surface, Teflon has one of the lowest coefficients of friction of any solid material.

This self-lubricating property is critical for applications like gears, bearings, bushings, and seals, where smooth, low-wear movement is essential for longevity and efficiency.

Superior Electrical Insulation

Teflon is an excellent electrical insulator with high dielectric strength. It does not conduct electricity, making it a vital material for insulators, connectors, and other electronic components where signal integrity and safety are paramount.

Inherent Durability and Resilience

Beyond its primary characteristics, Teflon is highly resistant to degradation from UV radiation, weather, and water. It will not rust, corrode, or decompose, ensuring long-lasting performance in exposed or harsh environments.

Understanding the Trade-offs and Machining Challenges

While Teflon's properties are advantageous for the final part, they introduce specific challenges during the machining process itself. Acknowledging these trade-offs is crucial for successful fabrication.

The Challenge of Softness

Teflon's softness makes it easy to cut, which can reduce tool wear and allow for faster machining speeds compared to metals. However, this same softness makes it difficult to clamp securely without deforming the workpiece. It can also lead to tool "chatter" if not managed correctly.

High Thermal Expansion

A significant challenge is Teflon's high coefficient of thermal expansion. Heat generated during cutting can cause the material to expand considerably, making it very difficult to hold tight tolerances. This requires careful thermal management and specialized machining techniques.

Stress Creep and Cold Flow

Under sustained pressure, even at room temperature, Teflon can slowly deform—a phenomenon known as "creep" or "cold flow." This must be accounted for in the design and machining of parts like seals and gaskets that will be under constant load.

Making the Right Choice for Your Application

Selecting Teflon is a strategic decision based on the specific demands of your project. Its unique profile makes it an ideal solution for certain problems and a poor choice for others.

- If your primary focus is survival in extreme chemical or thermal environments: Teflon is an excellent choice for valves, fittings, seals, and manifolds that must endure corrosive agents or drastic temperature swings.

- If your primary focus is creating low-friction, self-lubricating parts: It is the go-to material for high-performance bearings, bushings, slide plates, and gears where minimizing wear and friction is the main goal.

- If your primary focus is high-precision components with tight tolerances: Proceed with caution. The benefits must be weighed against the significant machining challenges related to thermal expansion and material softness.

By understanding both its exceptional properties and its unique machining demands, you can confidently leverage Teflon for applications where no other material will suffice.

Summary Table:

| Key Property | Advantage & Benefit |

|---|---|

| Chemical Resistance | Virtually inert; ideal for harsh chemicals, medical, and food-safe applications. |

| Thermal Stability | Performs from -200°C to 260°C; suitable for cryogenic to high-heat processes. |

| Low Friction | Self-lubricating; perfect for bearings, seals, and gears requiring minimal wear. |

| Electrical Insulation | Excellent dielectric strength; ensures safety and signal integrity in electronics. |

Need high-performance PTFE components that thrive in extreme conditions?

At KINTEK, we specialize in precision machining of Teflon (PTFE) for the semiconductor, medical, laboratory, and industrial sectors. We understand the unique challenges of working with PTFE—like thermal expansion and material softness—and leverage our expertise to deliver custom parts, from prototypes to high-volume orders, that meet your exact specifications.

Let us help you solve your most demanding application challenges. Contact our experts today to discuss your project and get a quote!

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Customizable PTFE Rods for Advanced Industrial Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

People Also Ask

- What are the key advantages of PTFE? Unmatched Performance for Extreme Environments

- How does PTFE contribute to low friction and wear resistance? Achieve Superior Performance with Advanced Materials

- What are the future considerations for machining Teflon? Mastering Material Challenges with Smart Tech

- What are the key considerations when machining Teflon? Master Precision Machining for Soft Polymers

- What are the best practices for achieving tight tolerances in Teflon (PTFE) machining? Master Precision for Demanding Applications