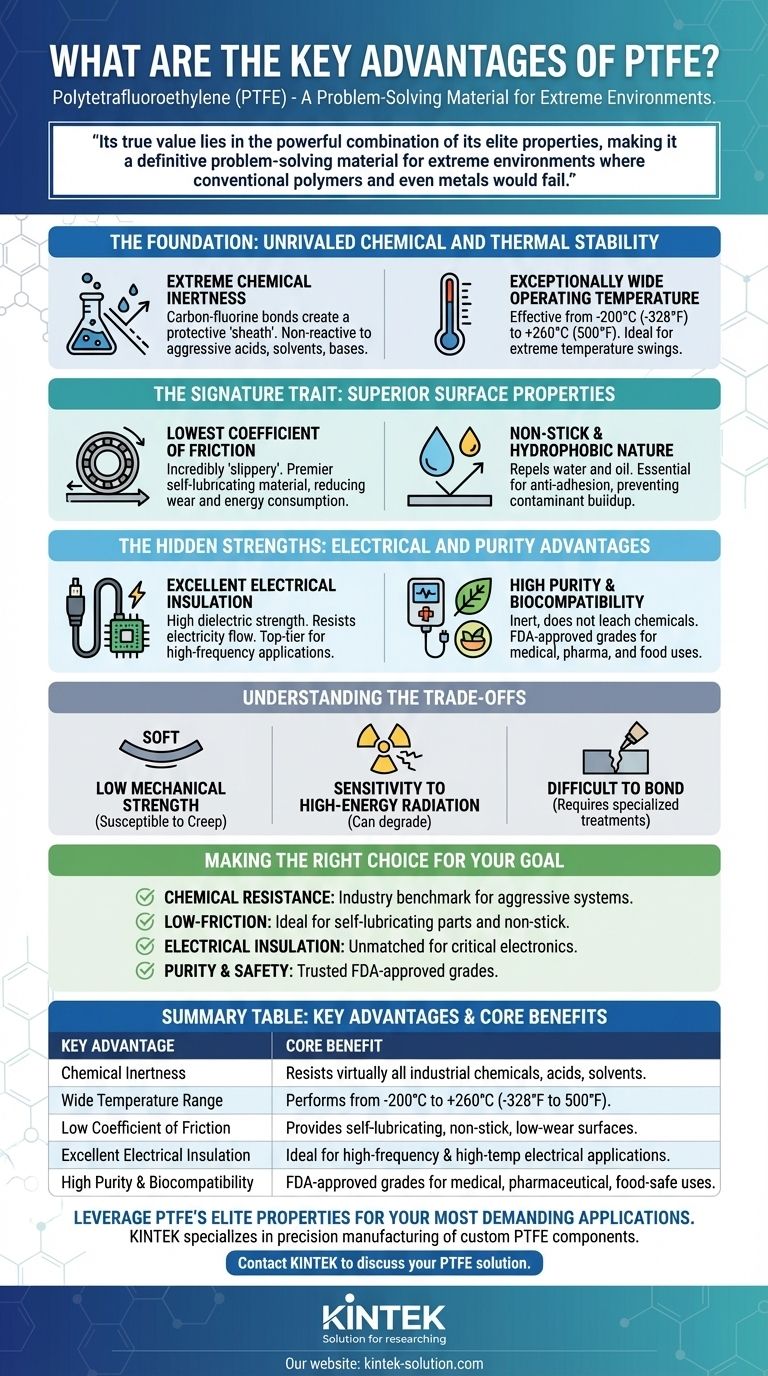

The primary advantages of Polytetrafluoroethylene (PTFE) stem from its unique molecular structure. This structure, composed of incredibly strong carbon-fluorine bonds, gives the material its defining characteristics: near-total chemical inertness, an extremely wide operating temperature range, an exceptionally low coefficient of friction, and superb electrical insulation properties.

PTFE is rarely chosen for a single attribute. Its true value lies in the powerful combination of its elite properties, making it a definitive problem-solving material for extreme environments where conventional polymers and even metals would fail.

The Foundation: Unrivaled Chemical and Thermal Stability

The core of PTFE's utility is its ability to withstand conditions that would degrade most other materials. This resilience is not accidental; it is a direct result of its chemical makeup.

### Extreme Chemical Inertness

The carbon-fluorine bond is one of the strongest single bonds in organic chemistry. This creates a protective "sheath" of fluorine atoms around the carbon backbone.

This molecular armor makes PTFE non-reactive and insoluble to virtually all industrial chemicals, including aggressive acids, solvents, and bases. It is this quality that makes it a default choice for seals, gaskets, and linings in chemical processing.

### An Exceptionally Wide Operating Temperature

PTFE maintains its properties across a vast thermal spectrum, a range few other polymers can match.

It can operate effectively in cryogenic conditions as low as -200°C (-328°F) and in continuous service at temperatures up to +260°C (500°F). This stability makes it invaluable for applications experiencing extreme temperature swings.

The Signature Trait: Superior Surface Properties

While its stability is foundational, PTFE is perhaps most famous for its unique surface characteristics. These properties are intrinsic to the material and do not degrade over time.

### The Lowest Coefficient of Friction

PTFE possesses one of the lowest coefficients of friction of any known solid material. This means it is incredibly "slippery," requiring very little energy to move a surface across it.

This property makes it a premier self-lubricating material for bearings, bushings, and other sliding or rotating parts, significantly reducing wear and energy consumption.

### Non-Stick and Hydrophobic Nature

This low surface energy also makes PTFE highly non-stick and non-wetting. It is both hydrophobic (repels water) and oleophobic (repels oil).

This anti-adhesion quality is essential for non-stick cookware coatings, but it is also critical in industrial applications to prevent the buildup of contaminants or viscous materials.

The Hidden Strengths: Electrical and Purity Advantages

Beyond its more visible traits, PTFE provides critical performance benefits in specialized, high-stakes applications.

### Excellent Electrical Insulation

PTFE is an outstanding electrical insulator with a very high dielectric strength and a low dielectric constant. It resists the flow of electricity exceptionally well.

This makes it a top-tier material for high-frequency applications, such as insulating cables and wires in aerospace and telecommunications equipment.

### High Purity and Biocompatibility

Because it is so inert, PTFE does not leach chemicals or contaminate its environment. Many grades are FDA-approved and considered food-safe and biocompatible.

This purity is non-negotiable in the medical, pharmaceutical, and food processing industries for applications like medical device components, tubing, and processing equipment linings.

Understanding the Trade-offs

No material is perfect, and PTFE's strengths create inherent limitations. Understanding these is key to using it effectively.

### Relatively Low Mechanical Strength

PTFE is a relatively soft material. Compared to engineering plastics or metals, it has lower tensile strength and is susceptible to creep (the tendency to deform slowly under stress). It is not a structural material.

### Sensitivity to High-Energy Radiation

While resistant to most environmental factors, PTFE can be degraded by high-energy radiation, such as gamma rays. This can break down its molecular structure and compromise its properties.

### Difficult to Bond

The same non-stick properties that make PTFE so valuable also make it extremely difficult to bond to other materials using conventional adhesives. This often requires specialized surface treatments like chemical etching.

Making the Right Choice for Your Goal

Selecting PTFE is a strategic decision based on the demands of the operating environment.

- If your primary focus is chemical resistance: PTFE is the industry benchmark for seals, linings, and components in chemically aggressive systems.

- If your primary focus is low-friction performance: It is the ideal choice for self-lubricating bearings, slide plates, and non-stick surfaces.

- If your primary focus is high-temperature electrical insulation: Its dielectric properties and thermal stability are unmatched for critical electronic applications.

- If your primary focus is purity and safety: FDA-approved grades of PTFE are a trusted solution for the food, medical, and pharmaceutical industries.

Ultimately, PTFE is the material of choice when performance and reliability in harsh conditions are non-negotiable.

Summary Table:

| Key Advantage | Core Benefit |

|---|---|

| Chemical Inertness | Resists virtually all industrial chemicals, acids, and solvents. |

| Wide Temperature Range | Performs from -200°C to +260°C (-328°F to 500°F). |

| Low Coefficient of Friction | Provides self-lubricating, non-stick, and low-wear surfaces. |

| Excellent Electrical Insulation | Ideal for high-frequency and high-temperature electrical applications. |

| High Purity & Biocompatibility | FDA-approved grades for medical, pharmaceutical, and food-safe uses. |

Leverage PTFE's elite properties for your most demanding applications. KINTEK specializes in the precision manufacturing of custom PTFE components—including seals, liners, and labware—for the semiconductor, medical, laboratory, and industrial sectors. From prototypes to high-volume orders, we deliver the reliability your critical processes require.

Contact KINTEK today to discuss your PTFE solution.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Square Trays for Industrial and Laboratory Use

- Customizable PTFE Rods for Advanced Industrial Applications

People Also Ask

- What are the best practices for achieving tight tolerances in Teflon (PTFE) machining? Master Precision for Demanding Applications

- Why is PTFE rod suitable for automotive applications? Boost Vehicle Performance & Durability

- What industries use PTFE machined parts and for what applications? Critical Components for Demanding Environments

- Why is CNC machining preferred for Teflon parts over other methods? Unlock Precision & Complex Designs

- How does PTFE contribute to low friction and wear resistance? Achieve Superior Performance with Advanced Materials