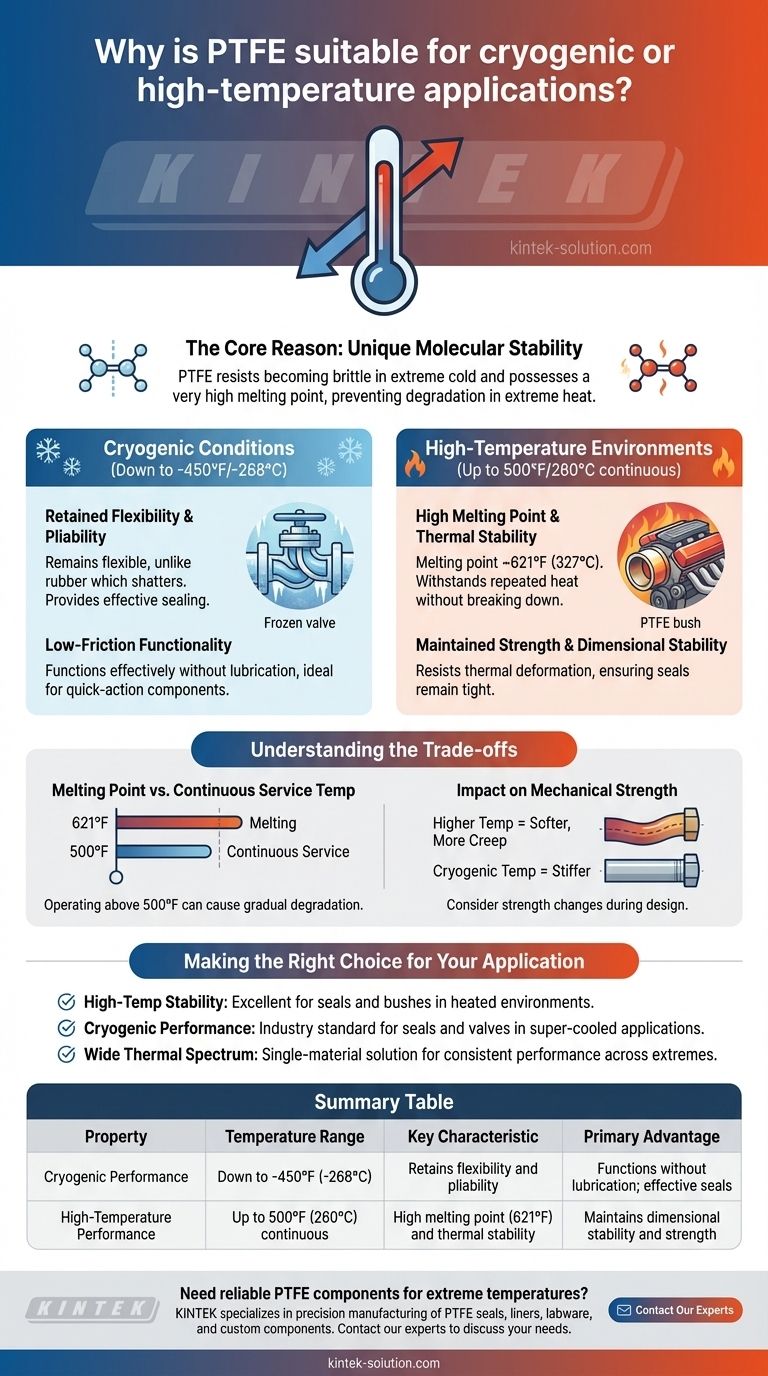

To put it simply, Polytetrafluoroethylene (PTFE) is suitable for both cryogenic and high-temperature applications because of its unique molecular stability. This stability allows it to resist becoming brittle and inflexible in extreme cold, while also possessing a very high melting point that prevents it from degrading or deforming in extreme heat, a combination of traits that is rare among polymers.

The core reason PTFE is so versatile is that it doesn't just tolerate extreme temperatures—it maintains its essential physical properties across an exceptionally wide operational range, from as low as -450°F to as high as 500°F, ensuring reliability where most other materials would fail.

Why PTFE Excels in High-Temperature Environments

The robust chemical bonds in PTFE are the foundation of its exceptional performance under thermal stress. This allows it to function reliably in applications like industrial ovens, engines, and other combustion processes.

High Melting Point and Thermal Stability

PTFE has a very high melting point of around 327°C (621°F). This is a critical property that allows it to replace weaker plastics that would fail in high-heat applications.

More importantly, it has excellent thermal stability, meaning it can withstand repeated exposure to high temperatures without breaking down or losing its structural integrity.

Maintained Strength and Dimensional Stability

Unlike many metals that can deform due to thermal expansion, PTFE components like bushes and seals maintain their strength and shape under heat.

This dimensional stability is crucial for ensuring that seals remain tight and parts continue to function as designed, even when temperatures fluctuate.

The Unique Advantage of PTFE in Cryogenic Conditions

While many materials become hard and brittle at extremely low temperatures, PTFE retains the physical properties needed for critical applications involving super-cooled media like liquid hydrogen or compressed natural gas (CNG).

Retained Flexibility and Pliability

This is the key differentiator between PTFE and materials like rubber. At cryogenic temperatures as low as -450°F (-268°C), PTFE remains flexible and pliable.

Elastomers and other plastics lose their elastomeric properties and shatter under stress in these conditions, but PTFE continues to provide effective sealing.

Low-Friction Functionality

PTFE has an extremely low coefficient of friction, allowing it to function effectively without external lubrication.

This is a significant advantage in cryogenic systems where traditional lubricants would freeze and become ineffective. This property makes PTFE ideal for components like ball valves that require quick, reliable action.

Understanding the Trade-offs

While PTFE's temperature range is impressive, it's crucial for engineers to understand the nuances of its performance specifications to ensure reliability and safety.

Melting Point vs. Continuous Service Temperature

The melting point of 327°C is the temperature at which the material physically changes state. However, its maximum continuous service temperature is lower, typically cited around 260°C (500°F).

Operating above this service temperature for extended periods can lead to a gradual degradation of mechanical properties, even if the material doesn't melt.

Impact of Temperature on Mechanical Strength

While PTFE maintains its core properties, its strength and stiffness are not constant across its entire temperature range.

At higher temperatures, PTFE becomes softer and more susceptible to creep (deformation under a constant load). Conversely, at cryogenic temperatures, it becomes stiffer. These factors must be considered during the design phase.

Making the Right Choice for Your Application

Selecting PTFE is about leveraging its unique stability for environments where conventional materials are not an option.

- If your primary focus is high-temperature stability: PTFE is an excellent choice for seals, O-rings, and bushes in heated environments, reliably outperforming lower-cost plastics.

- If your primary focus is cryogenic performance: PTFE is the industry standard for seals and valves in applications with super-cooled liquids, as it remains pliable and functional where rubbers would fail.

- If you need reliability across a wide thermal spectrum: PTFE provides a single-material solution that ensures consistent performance from cryogenic lows to high industrial heat.

Ultimately, PTFE's ability to maintain its structural and functional integrity makes it a proven engineering solution for the most demanding temperature extremes.

Summary Table:

| Property | Cryogenic Performance | High-Temperature Performance |

|---|---|---|

| Temperature Range | Down to -450°F (-268°C) | Up to 500°F (260°C) continuous service |

| Key Characteristic | Retains flexibility and pliability | High melting point (621°F) and thermal stability |

| Primary Advantage | Functions without lubrication; seals remain effective | Maintains dimensional stability and strength |

Need reliable PTFE components for extreme temperatures?

KINTEK specializes in precision manufacturing of PTFE seals, liners, labware, and custom components that perform reliably in the most demanding environments, from semiconductor processing to medical and industrial applications. Our expertise ensures your parts maintain integrity from cryogenic conditions to high-heat scenarios.

Contact our experts today to discuss your custom fabrication needs, from prototypes to high-volume orders.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Customizable PTFE Rods for Advanced Industrial Applications

- Custom PTFE Square Trays for Industrial and Laboratory Use

- Custom PTFE Volumetric Flasks for Advanced Scientific and Industrial Use

People Also Ask

- What temperature range can PTFE withstand? Ensuring Reliable Performance in Extreme Electrical Environments

- What are the advantages of using Teflon over other polymers? Unmatched Performance in Extreme Conditions

- Which industries commonly use Teflon and why? Its Unique Properties Solve Critical Engineering Challenges

- What industrial advantages does PTFE offer? Achieve Unmatched Reliability in Harsh Environments

- What are the uses of Teflon in personal care products? Enhance Makeup Longevity & Heat Protection

- What are the characteristics of PFA Teflon? | Extreme Performance Meets Design Freedom

- How does Teflon perform in outdoor applications? Unmatched Durability Against Weather and UV

- What are some unique properties of PTFE that make it valuable for various applications? The Ultimate Guide to PTFE's Elite Performance