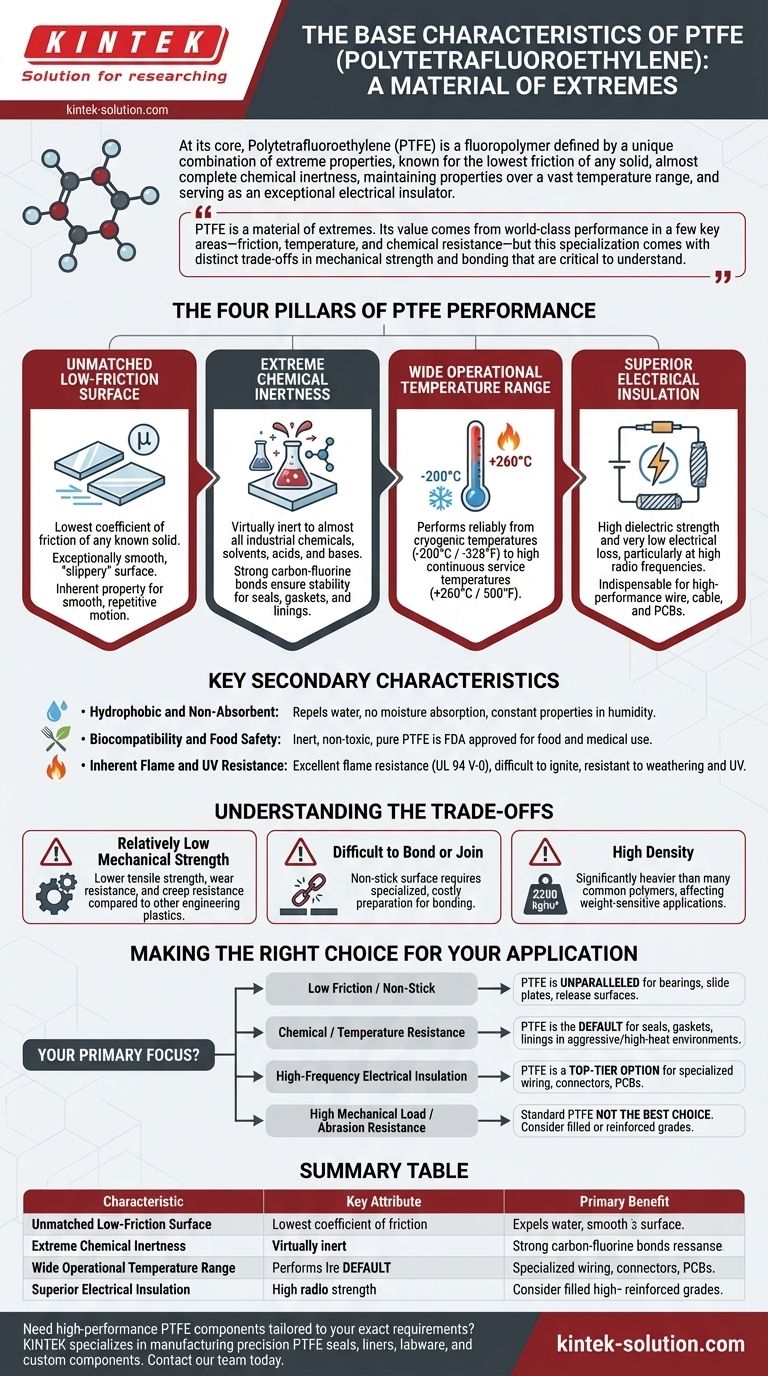

At its core, Polytetrafluoroethylene (PTFE) is a fluoropolymer defined by a unique combination of extreme properties. It is best known for having the lowest coefficient of friction of any solid, being almost completely chemically inert, maintaining its properties over a vast temperature range (from –200°C to +260°C), and serving as an exceptional electrical insulator.

PTFE is a material of extremes. Its value comes from world-class performance in a few key areas—friction, temperature, and chemical resistance—but this specialization comes with distinct trade-offs in mechanical strength and bonding that are critical to understand.

The Four Pillars of PTFE Performance

The remarkable utility of PTFE stems from four primary characteristics that set it apart from nearly all other polymers. Understanding these pillars is the key to leveraging the material correctly.

1. Unmatched Low-Friction Surface

PTFE exhibits the lowest coefficient of friction of any known solid material, often compared to wet ice on wet ice. This results in an exceptionally smooth, "slippery" surface.

This non-stick, low-friction quality is not a coating; it is an inherent property of the material itself. This makes it an ideal choice for applications requiring smooth, repetitive motion with minimal resistance, such as bearings, bushings, and gears.

2. Extreme Chemical Inertness

PTFE is virtually inert and non-reactive to almost all industrial chemicals, solvents, acids, and bases. Only a few exotic substances, like molten alkali metals, can affect it.

This extreme resistance is due to the very strong carbon-fluorine bonds that make up its molecular structure. These bonds are incredibly stable and difficult for chemical agents to break, making PTFE a premier choice for seals, gaskets, and linings in aggressive chemical environments.

3. Wide Operational Temperature Range

PTFE performs reliably across an exceptionally broad temperature spectrum. It remains functional and flexible at cryogenic temperatures down to -200°C (-328°F).

At the upper end, it has a continuous service temperature of +260°C (500°F) and does not melt until approximately 327°C (621°F). This thermal stability allows it to be used in high-temperature seals, gaskets, and insulation where other plastics would fail.

4. Superior Electrical Insulation

PTFE is one of the best electrical insulating materials known. It possesses a high dielectric strength and very low electrical loss, particularly at high radio frequencies.

Its electrical properties are also stable across a wide range of temperatures and frequencies. This makes it indispensable for high-performance applications like wire and cable insulation, capacitor films, and circuit board substrates.

Key Secondary Characteristics

Beyond the four pillars, several other properties contribute to PTFE's versatility.

Hydrophobic and Non-Absorbent

PTFE is hydrophobic, meaning it repels water and does not absorb moisture. This ensures its physical and electrical properties remain constant even in humid environments.

Biocompatibility and Food Safety

Because of its extreme inertness and non-toxic nature, pure PTFE is biocompatible and safe for direct contact with food. Many grades carry FDA approval for use in food processing, pharmaceutical, and medical applications.

Inherent Flame and UV Resistance

PTFE has excellent flame resistance, typically rated UL 94 V-0. It is difficult to ignite and does not promote flame spread. It is also highly resistant to weathering and UV light, making it suitable for outdoor use without degradation.

Understanding the Trade-offs

No material is perfect. The same properties that make PTFE unique also create its primary limitations. Being aware of these is critical for successful engineering.

Relatively Low Mechanical Strength

Compared to other engineering plastics like nylon or PEEK, standard PTFE has lower tensile strength, wear resistance, and resistance to "creep" (deformation under load). Its mechanical properties are often enhanced by adding fillers like glass, carbon, or bronze.

Difficult to Bond or Join

The non-stick surface that makes PTFE valuable also makes it extremely difficult to bond using conventional adhesives. Attaching PTFE to other materials requires specialized and often costly surface preparation techniques, such as chemical etching.

High Density

With a density of around 2200 kg/m³, PTFE is significantly heavier than many other common polymers. This can be a disadvantage in applications where minimizing weight is a primary design goal.

Making the Right Choice for Your Application

Use these guidelines to determine if PTFE is the right material for your specific goal.

- If your primary focus is low friction or a non-stick surface: PTFE is an unparalleled choice for bearings, slide plates, and release surfaces.

- If your primary focus is chemical or temperature resistance: PTFE is the default material for seals, gaskets, and linings in aggressive or high-heat environments.

- If your primary focus is high-frequency electrical insulation: PTFE's dielectric properties make it a top-tier option for specialized wiring, connectors, and PCBs.

- If your primary focus is high mechanical load or abrasion resistance: Standard PTFE is likely not the best choice unless you specify a filled or reinforced grade designed for these stresses.

Ultimately, PTFE should be chosen for its specialized, extreme properties where conventional materials fall short.

Summary Table:

| Characteristic | Key Attribute | Primary Benefit |

|---|---|---|

| Friction | Lowest coefficient of friction of any solid | Non-stick, smooth motion for bearings & bushings |

| Chemical Resistance | Inert to most chemicals, acids, and solvents | Ideal for seals & linings in aggressive environments |

| Temperature Range | Stable from -200°C to +260°C | Reliable performance in cryogenic & high-heat applications |

| Electrical Insulation | High dielectric strength, low electrical loss | Superior for high-frequency wiring, connectors & PCBs |

Need high-performance PTFE components tailored to your exact requirements? KINTEK specializes in manufacturing precision PTFE seals, liners, labware, and custom components for the semiconductor, medical, laboratory, and industrial sectors. Whether you need prototypes or high-volume production, our expertise ensures your application benefits from PTFE's extreme properties. Contact our team today to discuss your project and receive a custom solution that delivers unmatched reliability and performance.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

- Customizable PTFE Rods for Advanced Industrial Applications

- Custom PTFE Volumetric Flasks for Advanced Scientific and Industrial Use

People Also Ask

- What are the temperature range and mechanical properties of PTFE? The Ultimate Guide to Performance

- What is PTFE and what makes it versatile? The Ultimate High-Performance Polymer

- What is PTFE and why is it considered a valuable engineering material? Unlock Superior Performance in Demanding Applications

- How does Teflon demonstrate superior chemical resistance? Unlocking Its Molecular Fortress

- What is RPTFE and how does it differ from PTFE? Choose the Right Material for Your Application

- Why is flow regulation important in control systems? Ensure Stability, Safety, and Efficiency

- What types of finished products are made from PTFE? Seals, Bearings, Labware & More

- What issues arise when using reprocessed PTFE in chemical applications? Avoid Costly Contamination and Failure