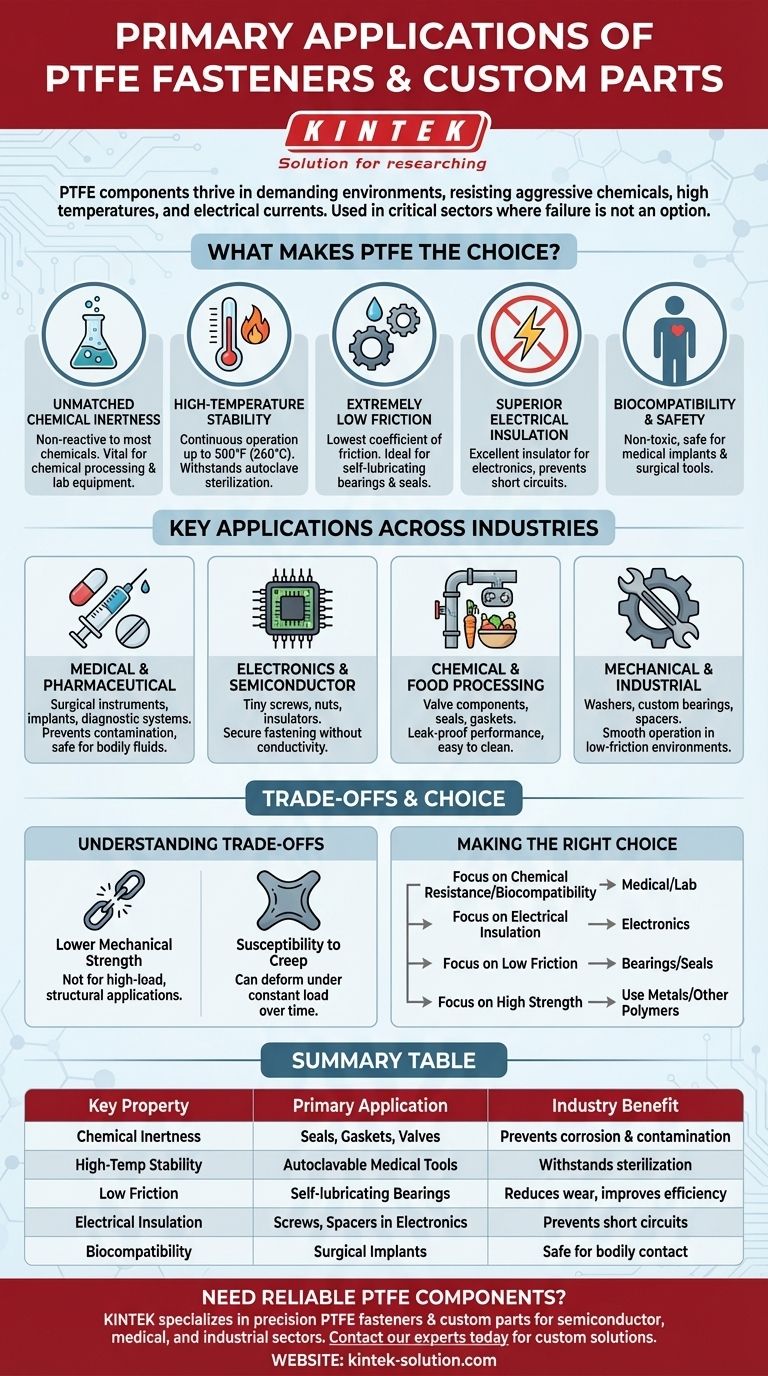

In short, PTFE fasteners and custom parts are primarily used in highly demanding environments where components must resist aggressive chemicals, high temperatures, and electrical currents. Their application is common in critical sectors like medical devices, electronics, and chemical processing where material failure is not an option.

The decision to use PTFE is rarely about mechanical strength; it's about ensuring operational integrity in conditions that would cause metals to corrode, and other plastics to degrade or melt.

What Makes PTFE the Material of Choice?

To understand its applications, we must first understand the unique properties that set Polytetrafluoroethylene (PTFE) apart. These characteristics make it a premier problem-solving material in engineering.

Unmatched Chemical Inertness

PTFE is non-reactive to nearly all chemicals, acids, and bases. This makes it invaluable for components used in chemical processing, fluid handling systems, and laboratory equipment where corrosion or contamination must be avoided.

High-Temperature Stability

PTFE components can operate continuously at temperatures up to 500°F (260°C). This allows them to be used in high-temperature industrial processes and, critically, to withstand sterilization methods like autoclaving in the medical field.

Extremely Low Friction

PTFE has one of the lowest coefficients of friction of any solid material, giving it a "non-stick" quality. This property is ideal for creating self-lubricating bearings, seals, and low-friction washers that reduce wear and improve efficiency.

Superior Electrical Insulation

As an excellent electrical insulator, PTFE is used to fabricate screws, spacers, and insulators for electronics and semiconductor manufacturing. It prevents short circuits and protects sensitive components from electrical interference.

Biocompatibility and Safety

PTFE is biocompatible, meaning it is non-toxic and does not react with human tissue. This fundamental property makes it a trusted material for medical implants, surgical tools, and components in diagnostic equipment.

Key Applications Across Industries

The properties of PTFE translate directly into specific, high-value applications where standard materials would fail.

Medical and Pharmaceutical

PTFE fasteners like screws and bolts are used in surgical instruments and implants because they prevent contamination and are safe for direct contact with bodily fluids. Its chemical resistance is also vital for components in diagnostic and fluid-handling systems.

Electronics and Semiconductor

In this industry, tiny PTFE screws, nuts, and custom insulators are used to assemble sensitive electronic devices. Their role is to provide secure fastening without conducting electricity, ensuring the reliability of the final product.

Chemical and Food Processing

PTFE valve components, seals, and gaskets provide leak-proof performance in the presence of corrosive chemicals. Its non-stick surface also makes it easy to clean, a crucial requirement in food processing equipment.

Mechanical and Industrial

In general machinery, PTFE washers are used to distribute load in low-friction environments. Custom-machined PTFE bearings and spacers are prized for their ability to operate smoothly without external lubrication.

Understanding the Trade-offs

While its properties are exceptional, PTFE is not a universal solution. An objective assessment requires acknowledging its limitations.

Lower Mechanical Strength

PTFE is a relatively soft material. It does not possess the high tensile or shear strength of metals or even other high-performance polymers. It should not be used in high-load, structural applications.

Susceptibility to Creep

Under a constant, sustained load, PTFE can slowly deform over time—a phenomenon known as "creep." This must be factored into the design of joints, especially in applications where precise dimensions are critical over the long term.

Making the Right Choice for Your Goal

Selecting the right material depends entirely on the primary challenge you need to solve.

- If your primary focus is chemical resistance and biocompatibility: PTFE is an ideal choice for medical devices, lab equipment, and pharmaceutical processing.

- If your primary focus is electrical insulation: PTFE fasteners and parts are a superior solution for assembling sensitive electronics.

- If your primary focus is low friction or a non-stick surface: PTFE is perfect for creating self-lubricating bearings, seals, and easy-to-clean components.

- If your primary focus is high mechanical strength and rigidity: You should evaluate metals or other engineering polymers as your primary option.

Ultimately, choosing PTFE is a strategic decision for environments where material inertness and performance under extreme conditions are more critical than raw mechanical strength.

Summary Table:

| Key Property | Primary Application | Industry Benefit |

|---|---|---|

| Chemical Inertness | Seals, Gaskets, Valves | Prevents corrosion & contamination in chemical processing |

| High-Temp Stability | Autoclavable Medical Tools | Withstands sterilization up to 260°C (500°F) |

| Low Friction | Self-lubricating Bearings, Washers | Reduces wear and improves efficiency |

| Electrical Insulation | Screws, Spacers in Electronics | Prevents short circuits in sensitive devices |

| Biocompatibility | Surgical Implants, Lab Equipment | Safe for contact with bodily fluids and tissues |

Need reliable PTFE components for your critical application?

At KINTEK, we specialize in precision manufacturing of PTFA fasteners, seals, liners, and custom labware. Whether you require prototypes or high-volume orders for the semiconductor, medical, or industrial sectors, our expertise ensures your components meet the highest standards for chemical resistance, temperature stability, and electrical insulation.

Contact our experts today to discuss your project requirements and receive a custom solution that guarantees performance and durability in your most demanding environments.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Volumetric Flasks for Advanced Scientific and Industrial Use

People Also Ask

- What is the working temperature range of PTFE? Master Extreme Heat and Cryogenic Applications

- What are the base characteristics of PTFE? Unlocking Extreme Performance in Friction, Temperature, and Chemical Resistance

- Why is PTFE suitable for cryogenic or high-temperature applications? Unmatched Thermal Stability from -450°F to 500°F

- What are the unique properties of PTFE? Unlock Unmatched Performance in Demanding Applications

- What are the best practices for achieving tight tolerances in Teflon (PTFE) machining? Master Precision for Demanding Applications