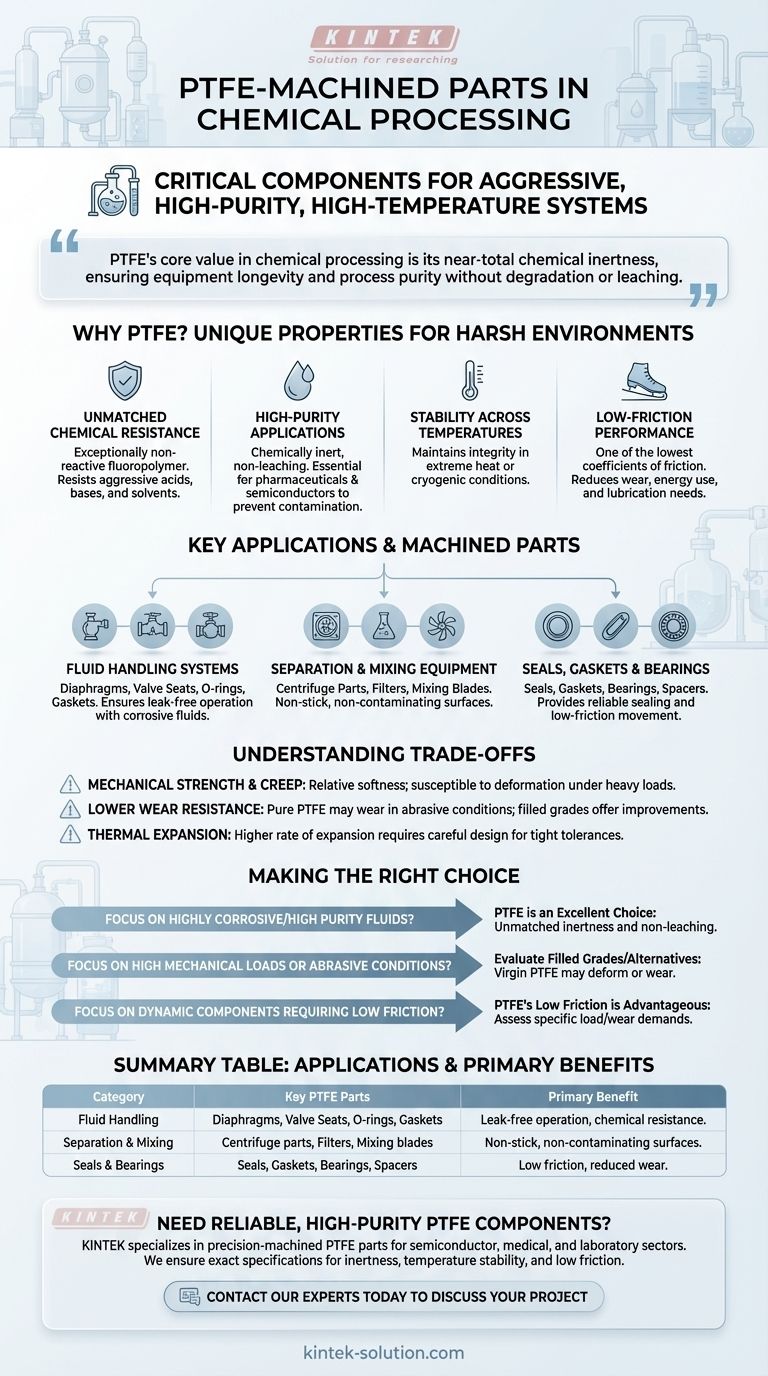

In chemical processing, PTFE-machined parts are critical components in systems designed to handle aggressive, high-purity, or high-temperature substances. Key applications include internal parts for pumps and valves, centrifuge components, filters, diaphragms, and mixing blades, all of which benefit from the material's unique properties.

The core reason PTFE is ubiquitous in chemical processing is its near-total chemical inertness. This unique property allows it to handle the most corrosive acids, bases, and solvents without degrading or leaching contaminants, ensuring both equipment longevity and process purity.

Why PTFE is the Material of Choice for Chemical Environments

To understand where PTFE is used, it's essential to first understand why it is selected over other polymers. Its value comes from a combination of unique characteristics that make it uniquely suited for harsh operational conditions.

Unmatched Chemical Resistance

PTFE is a fluoropolymer, making it exceptionally non-reactive. It offers unparalleled resistance to a vast range of industrial chemicals, including concentrated acids and aggressive solvents that would destroy most other materials.

High-Purity Applications

Because PTFE is chemically inert, it does not leach or contaminate the media it contacts. This is critical in manufacturing high-purity chemicals, pharmaceuticals, or semiconductors, where even trace amounts of contamination can ruin a batch.

Stability Across Wide Temperatures

Machined PTFE parts maintain their integrity and performance across a very broad temperature range. This makes them suitable for processes involving extreme heat or cryogenic applications without becoming brittle or degrading.

Low-Friction Performance

PTFE has one of the lowest coefficients of friction of any solid material, often compared to wet ice on wet ice. This makes it ideal for dynamic components like bearings, seals, and pump parts, as it reduces wear, energy consumption, and the need for lubrication.

A Closer Look at Key Applications

These fundamental properties translate directly into specific, high-value applications within chemical processing plants and laboratory equipment.

Fluid Handling Systems (Pumps & Valves)

Pumps and valves are the heart of any fluid processing system. PTFE is machined into critical internal components like diaphragms, valve seats, O-rings, and gaskets to ensure leak-free operation and long service life, even when handling corrosive fluids.

Separation and Mixing Equipment

Components like centrifuge parts, filters, and mixing blades are frequently machined from PTFE. The material’s non-stick surface prevents material buildup, while its inertness ensures the product is not contaminated during separation or agitation.

Seals, Gaskets, and Bearings

In any complex assembly, preventing leaks and reducing wear on moving parts is paramount. PTFE seals and gaskets provide reliable sealing against aggressive chemicals, while PTFE bearings and spacers allow for smooth, low-wear movement in rotating equipment.

Understanding the Trade-offs of Machined PTFE

While its advantages are significant, PTFE is not a universal solution. An objective assessment requires acknowledging its limitations.

Mechanical Strength and Creep

Compared to metals or other engineering plastics, virgin PTFE is a relatively soft material. Under a sustained, heavy load, it can be susceptible to "creep," or slow deformation over time.

Lower Wear Resistance

While its friction is low, pure PTFE can exhibit relatively high wear rates in highly abrasive applications. For these scenarios, filled grades of PTFE (e.g., glass- or carbon-filled) are often specified to improve durability.

Thermal Expansion

PTFE has a higher coefficient of thermal expansion than many other materials. This must be accounted for during the design of parts that require extremely tight tolerances and will operate across a wide temperature range.

Making the Right Choice for Your Application

Selecting the right material requires matching its properties to your primary operational goal.

- If your primary focus is handling highly corrosive or high-purity fluids: PTFE is an excellent first choice due to its unmatched chemical inertness and non-leaching properties.

- If your primary focus is high mechanical loads or abrasive conditions: You should evaluate filled grades of PTFE or alternative high-performance polymers, as virgin PTFE may deform or wear prematurely.

- If your primary focus is dynamic components requiring low friction: PTFE's exceptionally low coefficient of friction is a major advantage for seals and bearings, but be sure to assess the specific load and wear demands of the application.

Ultimately, understanding both the strengths and limitations of PTFE is the key to leveraging its remarkable capabilities in demanding chemical environments.

Summary Table:

| Application Category | Key PTFE-Machined Parts | Primary Benefit |

|---|---|---|

| Fluid Handling Systems | Diaphragms, Valve Seats, O-rings, Gaskets | Leak-free operation with corrosive fluids |

| Separation & Mixing Equipment | Centrifuge parts, Filters, Mixing blades | Non-stick, non-contaminating surfaces |

| Seals & Bearings | Seals, Gaskets, Bearings, Spacers | Low friction, reduced wear, chemical resistance |

Need reliable, high-purity PTFE components for your chemical processing equipment? KINTEK specializes in precision-machined PTFE parts—from seals and liners to custom labware—for the semiconductor, medical, laboratory, and industrial sectors. We ensure your components meet exact specifications for chemical inertness, temperature stability, and low friction. Contact our experts today to discuss your project, from prototypes to high-volume orders.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Customizable PTFE Rods for Advanced Industrial Applications

People Also Ask

- How do PTFE components compare to metal components? Choose the Right Material for Your Application

- What is the temperature tolerance range of PTFE compensators? Ideal for Extreme Heat and Cryogenic Systems

- In which industries are PTFE bellow mechanical seals commonly used? The Ultimate Solution for Corrosive Fluids

- What role does thermal history play in the processing of PTFE? Master Heat Control for Superior Components

- What types of products can be made from PTFE sheets in the chemical industry? | Gaskets, Liners & Seals

- What are the overall benefits of PTFE spring energized seals for oil and gas operations? Achieve Unmatched Reliability in HPHT Environments

- How does PTFE's chemical resistance benefit its use in liners? Ensure Total Containment and Purity

- What design parameter must be considered when applying wide contact to spring-activated PTFE lip seals? Prevent Bell Mouthing to Avoid Catastrophic Leakage