To put it directly, PTFE bellow mechanical seals are used across nearly every major industrial sector, including chemical, pharmaceutical, aerospace, food processing, electronics, and metallurgy. Their widespread adoption is not tied to a specific industry, but to a specific, critical challenge: safely sealing and transporting highly corrosive fluids.

The key takeaway is not which industry uses these seals, but why. PTFE bellow seals are the default solution for applications involving aggressive chemicals, such as strong acids and oxidizing agents, where standard materials would quickly fail. Their selection is driven by the chemical environment, not the industry label.

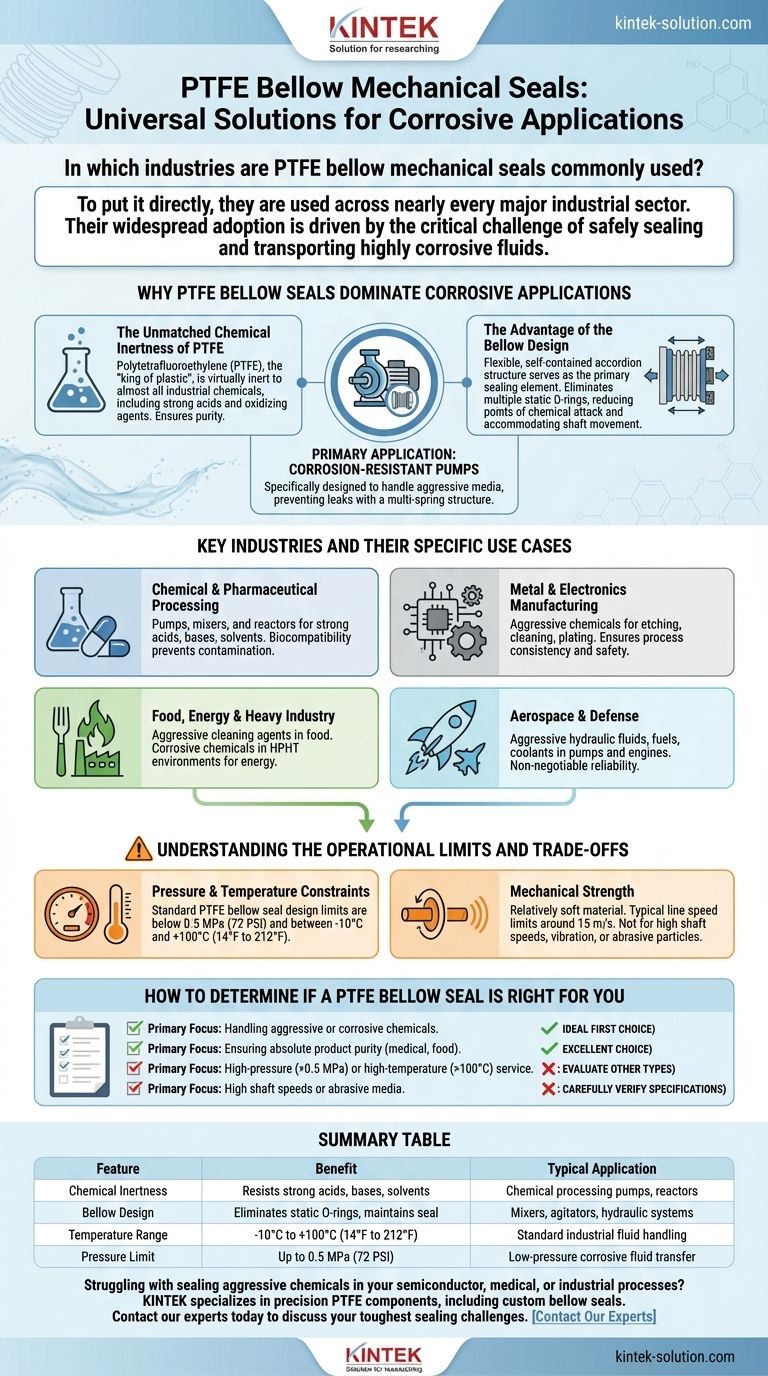

Why PTFE Bellow Seals Dominate Corrosive Applications

The value of a PTFE bellow seal comes from a combination of its unique material properties and an intelligent mechanical design. This pairing creates a robust solution for otherwise hazardous or impossible sealing challenges.

The Unmatched Chemical Inertness of PTFE

Polytetrafluoroethylene (PTFE) is a synthetic polymer often called the "king of plastic" for its exceptional corrosion resistance.

It is virtually inert to almost all industrial chemicals, including strong acids and oxidizing agents. This allows it to be used in any kind of chemical medium for extended periods without degradation.

This chemical inertness, along with its non-stick properties, makes it invaluable for processes where purity is essential, such as in the pharmaceutical or food and beverage industries.

The Advantage of the Bellow Design

The bellow itself is a flexible, accordion-like structure that serves as the primary sealing element.

This design is self-contained and eliminates the need for multiple static O-rings that could become points of chemical attack and failure. The bellow can expand and contract to accommodate shaft movement and maintain a consistent seal face pressure.

Combined with PTFE, the entire unit that comes into contact with the aggressive fluid is made from a chemically inert material, ensuring seal integrity and longevity.

Primary Application: Corrosion-Resistant Pumps

The most common application for PTFE bellow seals is in corrosion-resistant pumps.

These pumps are specifically designed to handle aggressive media, and the seal is the most critical component for preventing leaks. The PTFE bellow seal with a multi-spring structure is the most widely used type in this role.

Key Industries and Their Specific Use Cases

While the principle is universal, the specific application of PTFE bellow seals varies by industry. Understanding these use cases provides a clearer picture of their function.

Chemical and Pharmaceutical Processing

This is the primary market for PTFE bellow seals. They are used in pumps, mixers, and reactors that handle strong acids, bases, solvents, and other highly reactive chemicals.

In pharmaceutical and medical manufacturing, their biocompatibility and non-stick surface prevent contamination and ensure product purity in devices like autoclaves and surgical tools.

Metal and Electronics Manufacturing

Industries like metal surface treatment and electronics fabrication rely on aggressive chemicals for etching, cleaning, and plating.

PTFE bellow seals are essential for containing these fluids safely, preventing hazardous leaks and ensuring the consistency of the chemical processes.

Aerospace and Defense

These sectors utilize PTFE seals in applications involving aggressive hydraulic fluids, fuels, and coolants.

The seals are found in pumps, hydraulic systems, and engines where reliability under demanding conditions is non-negotiable.

Food, Energy, and Heavy Industry

In the food industry, PTFE seals are used where aggressive cleaning agents are present.

In the energy sector, including atomic and petroleum industries, they handle corrosive chemicals used in processing, downhole tools, and high-pressure, high-temperature (HPHT) environments.

Understanding the Operational Limits and Trade-offs

Despite its remarkable chemical properties, a PTFE bellow seal is not a universal solution. Its effectiveness is bound by specific mechanical and thermal limitations that are critical to understand.

Pressure and Temperature Constraints

The operational limits of the seal design are often more restrictive than the raw material properties of PTFE.

A standard PTFE bellow seal is typically rated for pressures below 0.5 MPa (72 PSI) and temperatures between -10°C and +100°C (14°F to 212°F). Exceeding these limits can lead to seal failure.

Mechanical Strength

PTFE is a relatively soft material compared to metal. While its low-friction surface is an advantage, it lacks the rigidity to handle high shaft speeds or environments with significant vibration or abrasive particles.

Typical line speed limits are around 15 m/s. Applications requiring higher pressure or mechanical robustness may require a different seal design, such as one with metal bellows.

How to Determine if a PTFE Bellow Seal is Right for You

Focus on the operational demands of your specific application to make the correct choice.

- If your primary focus is handling aggressive or corrosive chemicals: This is the core strength of PTFE bellow seals, making them your ideal first choice.

- If your primary focus is high-pressure (>0.5 MPa) or high-temperature (>100°C) service: You should evaluate other seal types, as you are likely outside the standard operating window for a PTFE bellow design.

- If your primary focus is ensuring absolute product purity (medical, food): The chemical inertness and non-stick properties of PTFE make these seals an excellent choice.

- If your application involves high shaft speeds or abrasive media: Carefully verify the manufacturer's specifications, as the mechanical limitations of PTFE may require a more robust material.

Ultimately, the decision to use a PTFE bellow seal is defined by its unparalleled ability to solve the most difficult chemical sealing challenges.

Summary Table:

| Feature | Benefit | Typical Application |

|---|---|---|

| Chemical Inertness | Resists strong acids, bases, and solvents | Chemical processing pumps, pharmaceutical reactors |

| Bellow Design | Eliminates static O-rings, maintains seal under shaft movement | Mixers, agitators, hydraulic systems |

| Temperature Range | -10°C to +100°C (14°F to 212°F) | Standard industrial fluid handling |

| Pressure Limit | Up to 0.5 MPa (72 PSI) | Low-pressure corrosive fluid transfer |

Struggling with sealing aggressive chemicals in your semiconductor, medical, or industrial processes? KINTEK specializes in precision PTFE components, including custom bellow seals, liners, and labware. We offer tailored solutions from prototypes to high-volume orders, ensuring reliability in the most demanding environments. Contact our experts today to discuss how our PTFE expertise can solve your toughest sealing challenges.

Visual Guide

Related Products

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Teflon Balls for Advanced Industrial Applications

People Also Ask

- What is the disadvantage of using glass as a filler in PTFE? The Critical Trade-off for Wear Resistance

- How does Teflon's performance in extreme temperatures benefit industrial applications? Ensuring Reliable Performance from -200°C to +260°C

- What tests are conducted on PTFE sliding rubber bearings? Ensure Your Structure's Safety and Movement

- What are the differences between unfilled PTFE and mechanical grade PTFE? Choose the Right Material for Your Application

- What are the steps for installing a PTFE gasket? A Guide to a Leak-Free Seal

- What are the typical applications for low-friction piston seals? Optimize for Smooth Motion & Efficiency

- What are the key characteristics of PTFE oil seals? Unlock Superior Performance in Extreme Conditions

- What role do Teflon PTFE sheets play in sewing projects? Achieve Flawless, Professional Results