In short, low-friction piston seals are specified for dynamic, reciprocating applications where smooth, predictable motion, energy efficiency, and minimal heat generation are more critical than raw sealing power alone. They are essential in precision hydraulics, high-speed pneumatics, and sensitive instrumentation.

The decision to use a low-friction seal is not just about preventing leaks; it's about optimizing the performance of the entire system. You choose it when the quality of the movement is as important as the seal itself.

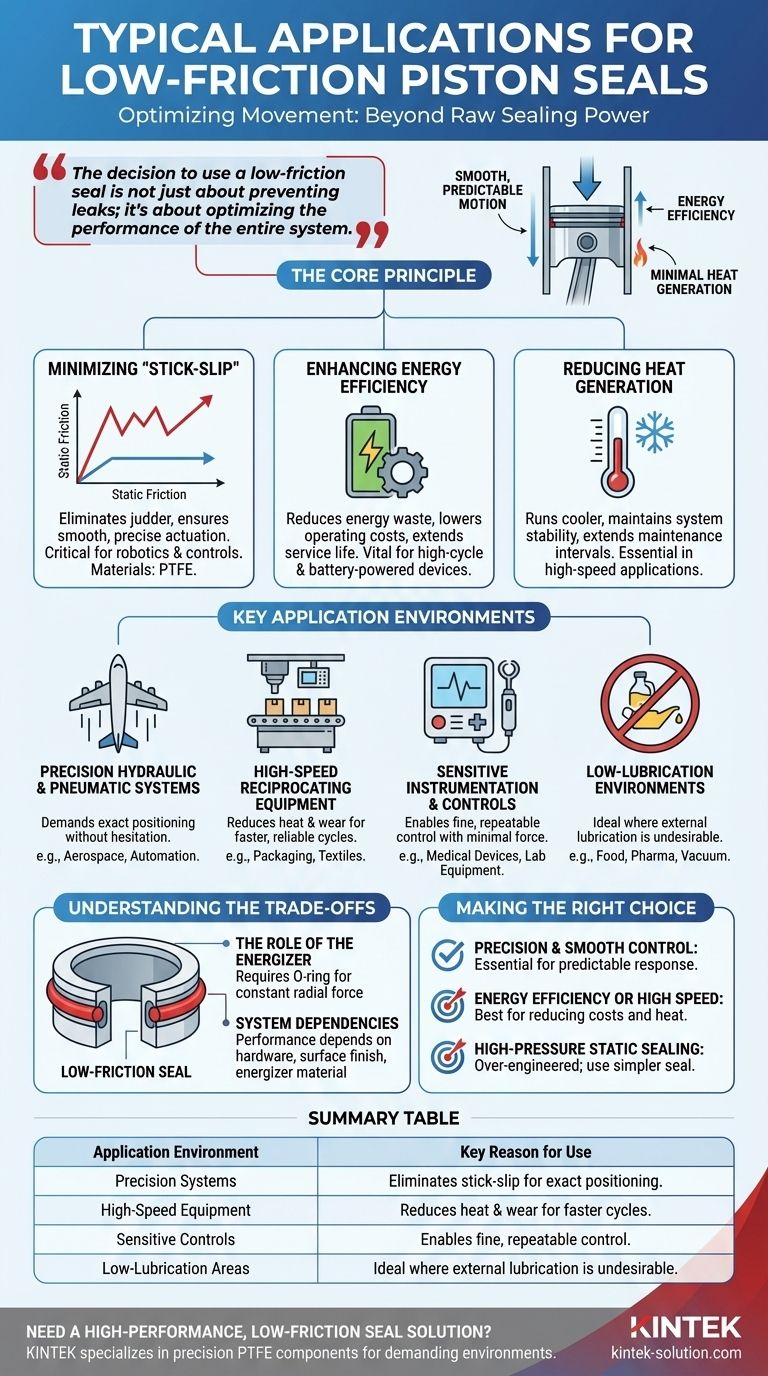

The Core Principle: When Low Friction is Non-Negotiable

A standard seal's primary job is to contain pressure. A low-friction seal must do this while solving for a different set of engineering challenges related to movement.

Minimizing "Stick-Slip" for Smooth Operation

The force required to start an object moving (static friction) is often higher than the force needed to keep it moving (dynamic friction). This difference causes stick-slip, resulting in jerky, uncontrolled motion.

Low-friction seals, often made from materials like PTFE, have static and dynamic friction values that are very close. This eliminates judder and ensures smooth, precise actuation, which is critical in robotics or control valves.

Enhancing Energy Efficiency

In any system, friction is wasted energy. In high-cycle equipment or battery-powered devices, this waste adds up significantly.

By minimizing frictional losses, these seals reduce the energy required to move the piston, leading to lower operating costs and longer service life for power sources.

Reducing Heat Generation

Friction generates heat. In high-speed applications, this heat can degrade lubricants, damage the seal material itself, and negatively affect system components.

Low-friction seals run cooler, which is vital for maintaining system stability and extending the time between maintenance intervals.

Key Application Environments

While the list of potential industries is vast, low-friction seals are chosen for specific reasons within those industries.

Precision Hydraulic and Pneumatic Systems

Applications like aerospace flight controls, industrial automation, and mobile equipment hydraulics demand exact positioning. Low-friction seals ensure that the actuator responds precisely to control inputs without hesitation or overshoot.

High-Speed Reciprocating Equipment

Think of can and package filling machines, textile looms, or manufacturing presses. In these high-speed, high-cycle environments, low-friction seals reduce heat and wear, enabling faster operation and greater reliability.

Sensitive Instrumentation and Controls

Medical devices, cryogenic liquid control valves, and laboratory equipment often require tiny, precise adjustments. A low-friction seal ensures that the force applied by the user or control system is not lost to friction, allowing for fine, repeatable control.

Low-Lubrication Environments

Many low-friction materials are inherently self-lubricating. This makes them ideal for applications where external lubrication is undesirable or impossible, such as in food processing, pharmaceutical production, or vacuum service.

Understanding the Trade-offs

Opting for a low-friction seal introduces a different set of design considerations compared to a simple, robust elastomer seal.

The Role of the Energizer

Materials like PTFE that offer the lowest friction are also quite rigid and lack the inherent elasticity of rubber. They cannot seal effectively on their own.

For this reason, they are almost always used with an O-ring energizer. The O-ring provides the constant radial force needed to press the low-friction seal jacket against the cylinder wall, ensuring a reliable seal.

System Dependencies

The performance of a low-friction seal is highly dependent on the entire system. Mating surface finishes, hardware tolerances, and fluid compatibility must be carefully considered to realize the full benefit. The energizer material, not the PTFE jacket, often dictates the temperature and pressure limits of the complete seal.

Making the Right Choice for Your Goal

To determine if a low-friction seal is appropriate, you must first define your most important performance metric.

- If your primary focus is precision and smooth control: A low-friction seal is essential to eliminate stick-slip and ensure your system responds predictably.

- If your primary focus is energy efficiency or high speed: A low-friction design is the best choice to reduce operating costs, minimize heat buildup, and maximize operational tempo.

- If your primary focus is high-pressure sealing in a mostly static environment: A low-friction seal is likely over-engineered; a simpler, more robust elastomer seal is often a more practical and economical solution.

Ultimately, choosing a seal based on its frictional properties is key to designing a system that is not just sealed, but truly optimized for its intended purpose.

Summary Table:

| Application Environment | Key Reason for Use |

|---|---|

| Precision Hydraulic/Pneumatic Systems | Eliminates stick-slip for exact positioning (e.g., aerospace, automation). |

| High-Speed Reciprocating Equipment | Reduces heat and wear for faster, more reliable cycles (e.g., packaging machines). |

| Sensitive Instrumentation & Controls | Enables fine, repeatable control with minimal force (e.g., medical devices). |

| Low-Lubrication Environments | Ideal where external lubrication is undesirable (e.g., food, pharmaceutical, vacuum). |

Need a High-Performance, Low-Friction Seal Solution?

Your application demands precision, efficiency, and reliability. At KINTEK, we specialize in manufacturing high-performance PTFE components, including seals, liners, and labware, for the most demanding environments in the semiconductor, medical, laboratory, and industrial sectors.

We prioritize precision production and offer custom fabrication—from prototypes to high-volume orders—to ensure your system is not just sealed, but truly optimized.

Let's discuss how our low-friction seals can enhance your design. Contact our engineering team today for a consultation.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Customizable PTFE Seals Filter Holders for Versatile Applications

People Also Ask

- What are the best practices for achieving tight tolerances in Teflon (PTFE) machining? Master Precision for Demanding Applications

- What are the main advantages of using PTFE parts in industrial applications? Unlock Unmatched Chemical Resistance and Reliability

- What tips can improve Teflon machining results? Master Sharp Tools, Heat Control, and Rigid Support

- How does PTFE contribute to low friction and wear resistance? Achieve Superior Performance with Advanced Materials

- What are the future considerations for machining Teflon? Mastering Material Challenges with Smart Tech