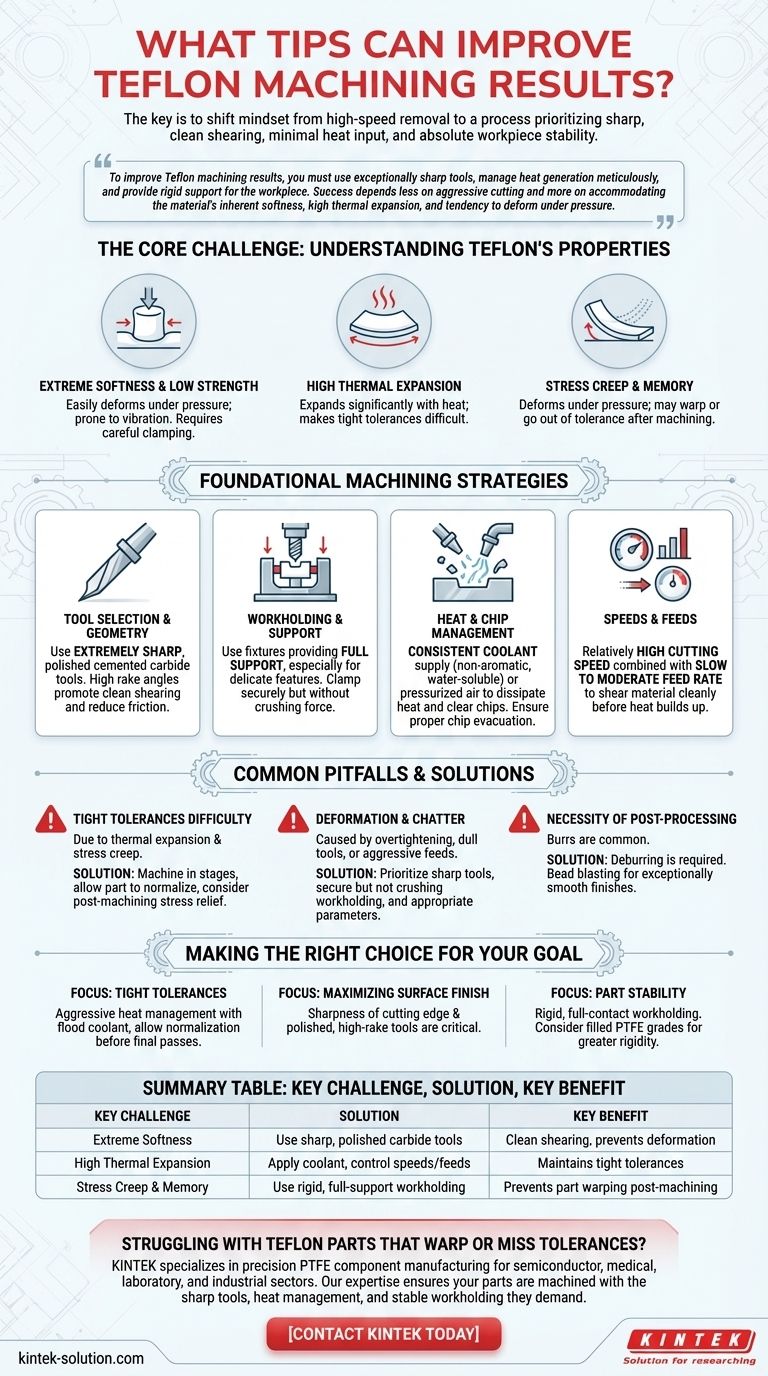

To improve Teflon machining results, you must use exceptionally sharp tools, manage heat generation meticulously, and provide rigid support for the workpiece. Success depends less on aggressive cutting and more on accommodating the material's inherent softness, high thermal expansion, and tendency to deform under pressure.

The core challenge of machining Teflon (PTFE) is not its hardness, but its unique combination of softness, thermal instability, and stress memory. The key to success is to shift your mindset from high-speed removal to a process that prioritizes sharp, clean shearing, minimal heat input, and absolute workpiece stability.

The Core Challenge: Understanding Teflon's Unique Properties

To machine Teflon effectively, you must first understand why it behaves so differently from metals and even other plastics. Its primary characteristics directly influence every choice you make, from tooling to coolants.

Extreme Softness and Low Strength

Teflon is exceptionally soft and has very low structural rigidity compared to materials like nylon or acetal.

This means it will easily deform or compress under tool pressure rather than cutting cleanly. It also makes the material prone to vibration and chatter if not supported properly.

High Thermal Expansion

Teflon has one of the highest coefficients of thermal expansion among common engineering materials. Even a small amount of heat generated from tool friction will cause it to expand significantly.

This expansion makes holding tight tolerances extremely difficult, as the part can change size during and after the machining process as it cools.

Stress Creep and Memory

When subjected to pressure from clamping or cutting, Teflon can "creep" or slowly deform. After the pressure is released, it may not fully return to its original shape.

This material memory can cause parts to warp or go out of tolerance hours or even days after they have been machined.

Foundational Machining Strategies

With a clear understanding of the material's challenges, you can implement specific strategies to counteract them and produce high-quality parts.

Tool Selection and Geometry

The right tool is the single most important factor for success.

Use extremely sharp cutting edges, as a dull tool will push and deform the material instead of shearing it. Cemented carbide tools are an excellent choice, but their sharpness and edge finish are paramount.

Tools with a highly polished surface and high rake angles are ideal. This geometry promotes a clean shearing action and reduces friction, which in turn minimizes heat buildup and prevents material from sticking to the tool.

Workholding and Support

Because of its softness, Teflon must be clamped securely but without excessive force that could crush or distort it.

Use fixtures that provide full support to the workpiece, especially for thin-walled or delicate features. This prevents vibration and deflection during the cut, which are major causes of poor surface finish and inaccuracy.

Heat and Chip Management

Controlling temperature is non-negotiable for precision work.

Use a consistent supply of coolant to dissipate heat and prevent thermal expansion. Non-aromatic, water-soluble coolants are highly effective. For some operations, pressurized air can be sufficient to clear chips and provide some cooling.

Proper chip clearance is also vital. Tools with deep flutes help evacuate the soft, stringy chips efficiently, preventing them from wrapping around the tool and generating more friction.

Speeds and Feeds

Your parameters should focus on creating a clean cut without generating excess heat.

Generally, this involves using a relatively high cutting speed combined with a slow to moderate feed rate. This allows the sharp tool to shear the material cleanly before significant heat can build up.

Understanding the Trade-offs and Common Pitfalls

Machining Teflon involves balancing competing factors. Being aware of the common failure points will help you troubleshoot and avoid them.

The Difficulty with Tight Tolerances

Achieving tight tolerances is the primary struggle. This is a direct result of thermal expansion and stress creep. A part that measures perfectly on the machine may be out of spec once it reaches room temperature.

For critical dimensions, consider machining in stages, allowing the part to normalize between roughing and finishing passes. In some cases, post-machining stress relief may be necessary.

The Risk of Deformation and Chatter

Overtightening a vise, using dull tools, or employing an aggressive feed rate will cause immediate problems.

These actions introduce too much pressure into the soft material, leading to part deformation, tool chatter, and a terrible surface finish. Always prioritize sharp tools and secure, but not crushing, workholding.

The Necessity of Post-Processing

Even with perfect technique, Teflon parts will have a burr after machining.

Deburring is a standard and required step. For applications requiring an exceptionally smooth surface, bead blasting can be an effective final finishing process.

Making the Right Choice for Your Goal

Your specific approach should be tailored to the most critical outcome for your component.

- If your primary focus is achieving tight tolerances: Aggressive heat management with flood coolant and allowing the material to normalize before final passes are non-negotiable.

- If your primary focus is maximizing surface finish: The sharpness of your cutting edge and the use of polished, high-rake tools are the most critical factors.

- If your primary focus is ensuring part stability after machining: Focus on rigid, full-contact workholding and consider using a filled grade of PTFE (like glass-filled) if the application allows, as it offers greater rigidity.

By respecting Teflon's unique properties instead of fighting them, you can achieve precise and repeatable results in your machining operations.

Summary Table:

| Key Challenge | Solution | Key Benefit |

|---|---|---|

| Extreme Softness | Use extremely sharp, polished carbide tools | Clean shearing, prevents deformation |

| High Thermal Expansion | Apply coolant, control speeds/feeds | Maintains tight tolerances |

| Stress Creep & Memory | Use rigid, full-support workholding | Prevents part warping post-machining |

Struggling with Teflon parts that warp or miss tolerances? KINTEK specializes in precision PTFE component manufacturing for the semiconductor, medical, laboratory, and industrial sectors. Our expertise in custom fabrication—from prototypes to high-volume orders—ensures your Teflon parts are machined with the sharp tools, heat management, and stable workholding they demand.

Contact KINTEK today to discuss your project and achieve reliable, high-quality results.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Customizable PTFE Rods for Advanced Industrial Applications

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

People Also Ask

- What is the significance of biocompatibility in PTFE fasteners for medical devices? Ensure Patient Safety and Device Reliability

- What are the advantages of PTFE rod over other materials? Superior Chemical & Thermal Performance

- How do fillers enhance the properties of modified PTFE gaskets? Improve Strength, Wear, and Creep Resistance

- How does modified PTFE differ from virgin PTFE? Unlock Superior Performance for Demanding Applications

- What are the recommended processing parameters for CNC machining PTFE? Master Heat Control for Precision Parts

- What are PTFE-based materials composed of for RF PCB stackups? A Guide to Engineered Composites

- What challenges do elastomeric seals face in oil and gas operations? Ensuring Reliability Under Extreme Conditions

- What are PTFE O-rings and their key characteristics? Solve Extreme Chemical & Thermal Sealing Challenges