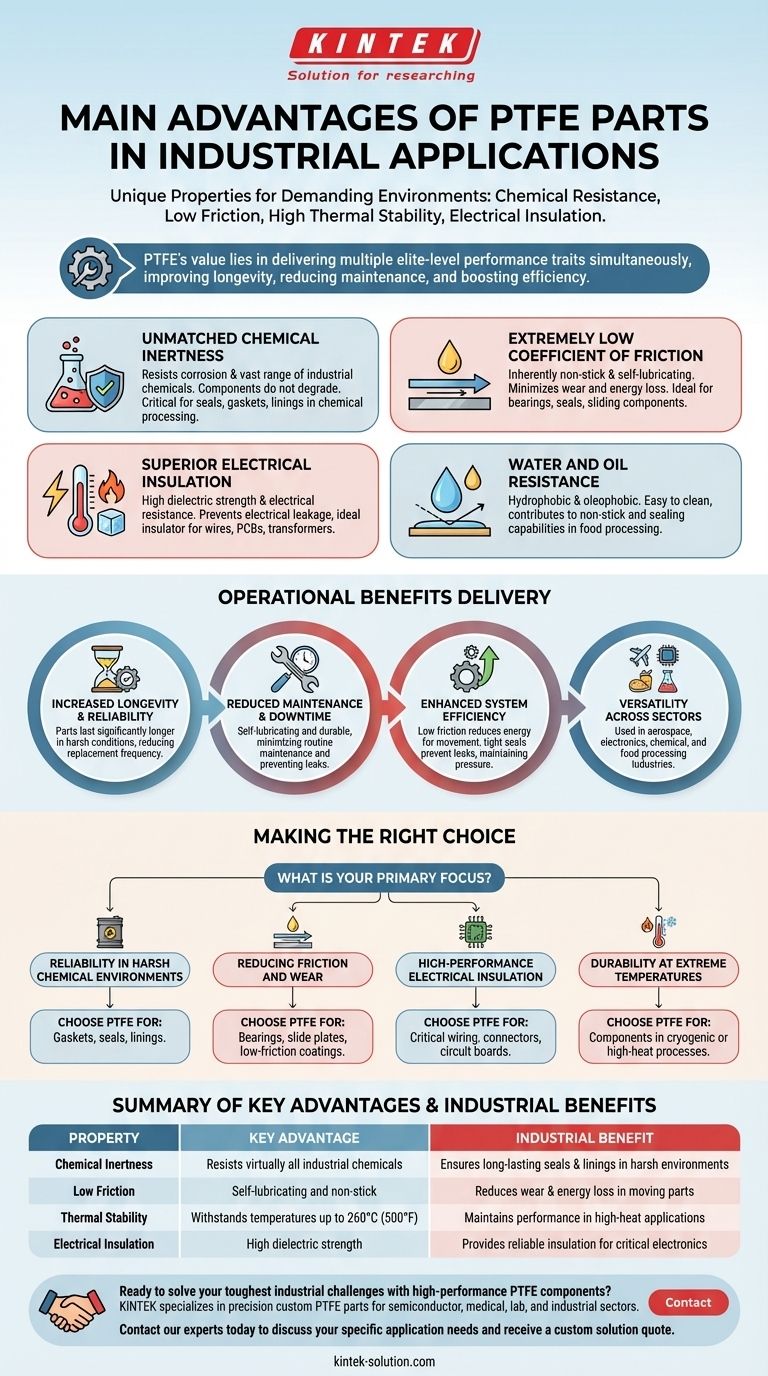

The primary advantages of PTFE parts in industrial applications stem from a unique combination of properties that other materials cannot match. Its core benefits include near-total chemical and corrosion resistance, an extremely low coefficient of friction, high-temperature stability, and excellent electrical insulation. These characteristics make it a uniquely reliable and versatile material for the most demanding operational environments.

PTFE's value isn't just one single attribute, but its ability to deliver multiple elite-level performance traits simultaneously. This allows it to function where other materials would quickly fail, directly improving system longevity, reducing maintenance, and boosting operational efficiency.

The Core Properties Driving Industrial Adoption

To understand why PTFE (polytetrafluoroethylene), often known by the brand name Teflon, is so prevalent, we must first examine its fundamental material characteristics. Each property solves a specific set of engineering challenges.

Unmatched Chemical Inertness

PTFE is renowned for its resistance to corrosion and a vast range of industrial chemicals. This inertness means components do not degrade when exposed to harsh substances.

This property is critical for parts like seals, gaskets, and linings used in chemical processing equipment, ensuring they maintain integrity and prevent leaks.

Extremely Low Coefficient of Friction

PTFE has one of the lowest friction coefficients of any solid material, making it inherently non-stick and self-lubricating.

This is ideal for dynamic parts like bearings, seals, or sliding components in automotive and aerospace systems, as it minimizes wear and energy loss without external lubricants.

High Thermal Stability

PTFE parts can operate consistently across a wide temperature range, withstanding heat up to 500°F (260°C).

This stability ensures that components used in high-temperature environments, such as aerospace gaskets or electrical insulators, maintain their shape and performance without melting or degrading.

Superior Electrical Insulation

PTFE possesses outstanding electrical properties, including high dielectric strength and electrical resistance.

It is an ideal insulator for wires, cables, transformers, and printed circuit boards (PCBs), preventing electrical leakage and ensuring reliable performance in electronic applications.

Water and Oil Resistance

The material is both hydrophobic (resists water) and oleophobic (resists oil), which contributes to its non-stick and sealing capabilities.

This characteristic makes PTFE parts easy to clean, a key advantage in food processing, and helps create tight, durable seals that are impervious to moisture and oil.

How These Properties Translate to Operational Benefits

The inherent properties of PTFE deliver tangible, real-world advantages that improve industrial processes, reduce costs, and enhance safety.

Increased Longevity and Reliability

Because PTFE resists chemical attack and thermal degradation, parts made from it last significantly longer, even in harsh conditions.

This durability reduces the frequency of component replacement, leading to more reliable machinery and predictable operational cycles.

Reduced Maintenance and Downtime

The combination of durability and low friction minimizes the need for routine maintenance. Self-lubricating parts eliminate the need for regular greasing, while long-lasting seals prevent leaks that would otherwise halt operations.

This directly translates to less operational downtime and lower lifetime costs for equipment.

Enhanced System Efficiency

In mechanical systems, low-friction PTFE components reduce the energy required for movement. In fluid systems, its tight sealing capabilities prevent leaks, ensuring pressure and purity are maintained.

These factors contribute to more efficient, cost-effective operations across the board.

Versatility Across Demanding Sectors

PTFE’s unique combination of properties makes it a go-to material in a wide array of industries.

It is used in aerospace for temperature-resistant seals, in electronics for high-performance insulation, in chemical processing for corrosion-proof linings, and in food processing for hygienic, non-stick surfaces.

Making the Right Choice for Your Application

Selecting a material depends entirely on the primary challenge you need to solve. PTFE offers a distinct solution for several common industrial goals.

- If your primary focus is reliability in harsh chemical environments: PTFE is the ideal choice for gaskets, seals, and linings due to its near-total chemical inertness.

- If your primary focus is reducing friction and wear in moving parts: Its self-lubricating nature makes it perfect for bearings, slide plates, and low-friction coatings.

- If your primary focus is high-performance electrical insulation: PTFE provides exceptional dielectric strength, making it a superior material for critical wiring, connectors, and circuit boards.

- If your primary focus is durability at extreme temperatures: Its high thermal stability ensures components maintain their integrity in everything from cryogenic applications to high-heat industrial processes.

Ultimately, PTFE is a powerful problem-solving material engineered to provide unmatched reliability where it matters most.

Summary Table:

| Property | Key Advantage | Industrial Benefit |

|---|---|---|

| Chemical Inertness | Resists virtually all industrial chemicals | Ensures long-lasting seals and linings in harsh environments |

| Low Friction | Self-lubricating and non-stick | Reduces wear and energy loss in moving parts |

| Thermal Stability | Withstands temperatures up to 260°C (500°F) | Maintains performance in high-heat applications |

| Electrical Insulation | High dielectric strength | Provides reliable insulation for critical electronics |

Ready to solve your toughest industrial challenges with high-performance PTFE components?

At KINTEK, we specialize in the precision manufacturing of custom PTFE parts—including seals, liners, and labware—for the semiconductor, medical, laboratory, and industrial sectors. Our expertise ensures your components deliver the unmatched chemical resistance, low friction, and thermal stability detailed in this article.

We partner with you from prototype to high-volume production, guaranteeing parts that enhance your system's longevity, reduce maintenance, and boost operational efficiency.

Contact our experts today to discuss your specific application needs and receive a custom solution quote.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Customizable PTFE Rods for Advanced Industrial Applications

- Custom PTFE Volumetric Flasks for Advanced Scientific and Industrial Use

- Custom PTFE Square Trays for Industrial and Laboratory Use

People Also Ask

- What challenges arise when machining PTFE (Teflon)? Overcome Softness, Heat, and Instability

- What fabrication services are available for PTFE? Shearing, Stamping, Laser Cutting, Molding & Machining

- What industrial benefits do PTFE-machined parts offer? Achieve Peak Performance in Demanding Applications

- What chemical processing applications involve PTFE-machined parts? Essential Components for Corrosive & High-Purity Systems

- What factors should be considered when choosing between Nylon and PTFE? Select the Right Material for Your Application