In industrial applications, Teflon's primary benefit in extreme temperatures is its unwavering stability. Unlike materials that become brittle in the cold or degrade in the heat, Teflon (PTFE) maintains its most valuable properties—such as low friction and chemical inertness—across an exceptionally wide operational range. This consistency ensures predictable, reliable performance in environments where other materials would fail.

The true value of Teflon is not simply its ability to survive extreme temperatures; it is the fact that its other critical engineering properties remain remarkably consistent across that entire thermal spectrum, from cryogenic lows to high industrial heat.

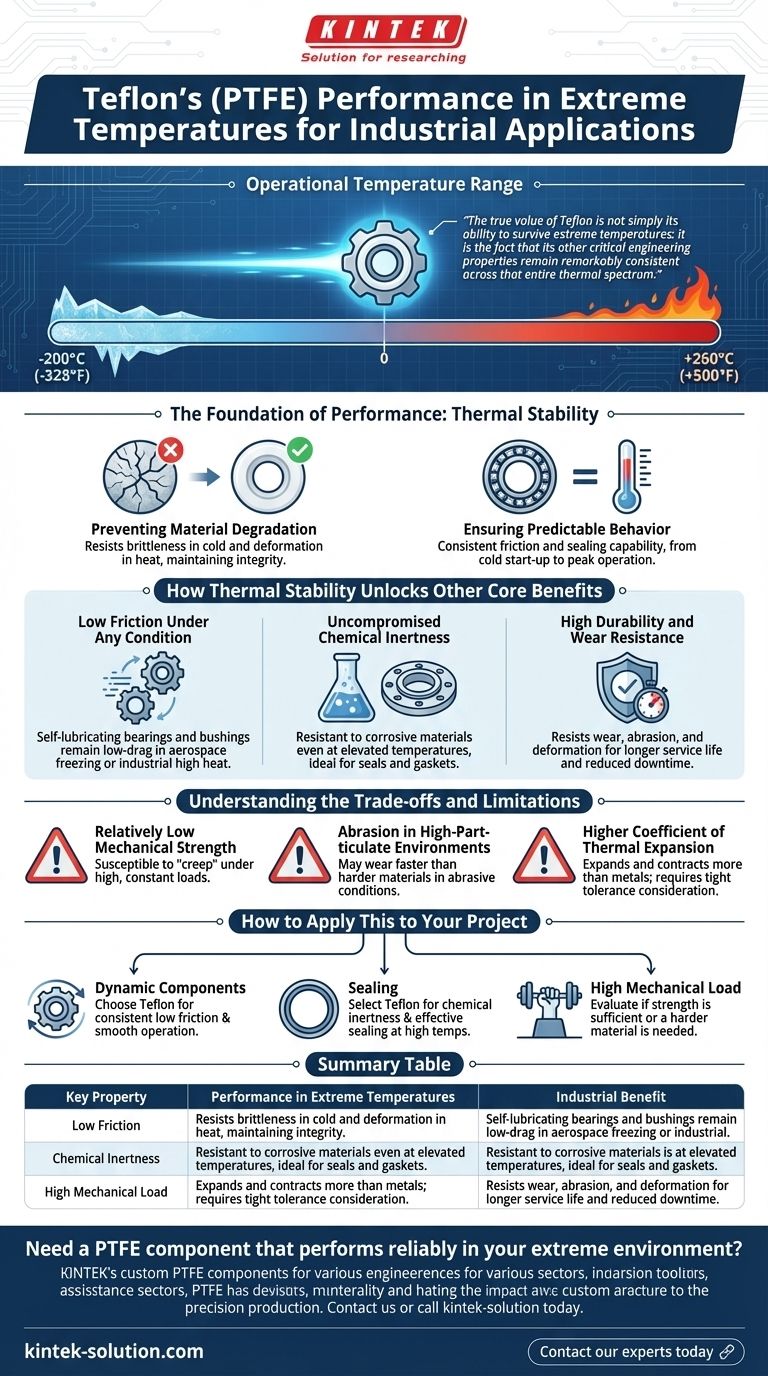

The Foundation of Performance: Thermal Stability

Teflon's defining characteristic is its ability to perform reliably under thermal stress. This stability is the bedrock upon which its other industrial benefits are built.

The Operational Temperature Range

Teflon functions effectively across a vast temperature window, typically from -200°C (-328°F) to +260°C (+500°F). This allows it to be used in everything from cryogenic liquid handling to high-temperature heat exchangers.

Preventing Material Degradation

Many polymers become brittle and crack at low temperatures or soften and deform at high temperatures. Teflon's molecular structure allows it to avoid this, maintaining its integrity and preventing catastrophic component failure.

Ensuring Predictable Behavior

The most critical aspect of this stability is consistency. Engineers can trust that a Teflon component will behave the same way—with the same friction and sealing capability—during a cold start-up as it does at peak operating temperature.

How Thermal Stability Unlocks Other Core Benefits

Temperature resistance is not an isolated feature; it is an enabling one. It allows Teflon's other elite properties to shine in environments where they are needed most.

Low Friction Under Any Condition

Teflon is renowned for its extremely low coefficient of friction. Its thermal stability ensures that components like bearings and bushings remain self-lubricating and low-drag whether they are operating in the freezing temperatures of aerospace applications or the high heat of industrial machinery.

Uncompromised Chemical Inertness

Teflon is resistant to nearly all industrial chemicals and solvents. This inertness does not diminish at high temperatures, making it the ideal material for seals and gaskets in chemical processing plants where corrosive materials are handled under heat.

High Durability and Wear Resistance

Because Teflon does not soften significantly at higher temperatures, it effectively resists wear, abrasion, and deformation. This leads to a longer service life for critical parts, reducing machinery downtime and maintenance costs.

Understanding the Trade-offs and Limitations

No material is perfect. To use Teflon effectively, it's crucial to understand its limitations, especially in contrast to metals or other engineered polymers.

Relatively Low Mechanical Strength

Teflon is a relatively soft material. Under high, constant loads, it can be susceptible to "creep" or cold flow, where the material slowly deforms over time.

Abrasion in High-Particulate Environments

While durable, Teflon may not be the optimal choice for environments with high levels of abrasive particulates, where harder materials might offer a longer lifespan.

Higher Coefficient of Thermal Expansion

Teflon expands and contracts with temperature changes more than metals do. This must be accounted for in designs that require extremely tight tolerances across a wide temperature range.

How to Apply This to Your Project

Your specific goal will determine if Teflon's unique combination of properties is the right solution for your challenge.

- If your primary focus is dynamic components (bearings, bushings): Choose Teflon for its consistently low friction across extreme temperature cycles, which ensures smooth operation and reduces wear.

- If your primary focus is sealing (gaskets, O-rings): Select Teflon when you need a seal that remains inert and effective against aggressive chemicals, even at elevated temperatures.

- If your primary focus is high mechanical load: Carefully evaluate if Teflon's strength is sufficient, or if a harder, more rigid material is required despite potential trade-offs in friction or chemical resistance.

By understanding its complete performance profile, you can leverage Teflon not just to endure extreme temperatures, but to guarantee consistent and reliable operation within them.

Summary Table:

| Key Property | Performance in Extreme Temperatures | Industrial Benefit |

|---|---|---|

| Thermal Stability | Performs from -200°C to +260°C | Prevents brittle failure or deformation |

| Low Friction | Remains consistent across the thermal range | Ensures self-lubricating bearings and bushings |

| Chemical Inertness | Unaffected by heat or cold | Creates reliable seals against corrosive chemicals |

| Durability | Resists wear and abrasion at high temperatures | Extends component service life, reducing downtime |

Need a PTFE component that performs reliably in your extreme environment?

KINTEK specializes in manufacturing high-performance, custom PTFE components—including seals, liners, labware, and more—for the semiconductor, medical, laboratory, and industrial sectors. Our precision production ensures your parts maintain critical properties like low friction and chemical resistance across the entire operational temperature range, from cryogenic applications to high-heat processes.

Whether you require prototypes or high-volume orders, we deliver solutions that guarantee consistency and durability.

Contact our experts today to discuss your specific requirements and get a quote!

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Customizable PTFE Rods for Advanced Industrial Applications

People Also Ask

- What are the material advantages of machining Teflon? Unlock Unmatched Chemical & Thermal Resistance

- What are the primary applications of PTFE fasteners and custom parts? Critical Solutions for Extreme Environments

- What are the unique properties of PTFE? Unlock Unmatched Performance in Demanding Applications

- What is PTFE commonly known as and what are its unique properties? Unlock Unmatched Chemical & Thermal Resistance

- Why is PTFE suitable for cryogenic or high-temperature applications? Unmatched Thermal Stability from -450°F to 500°F