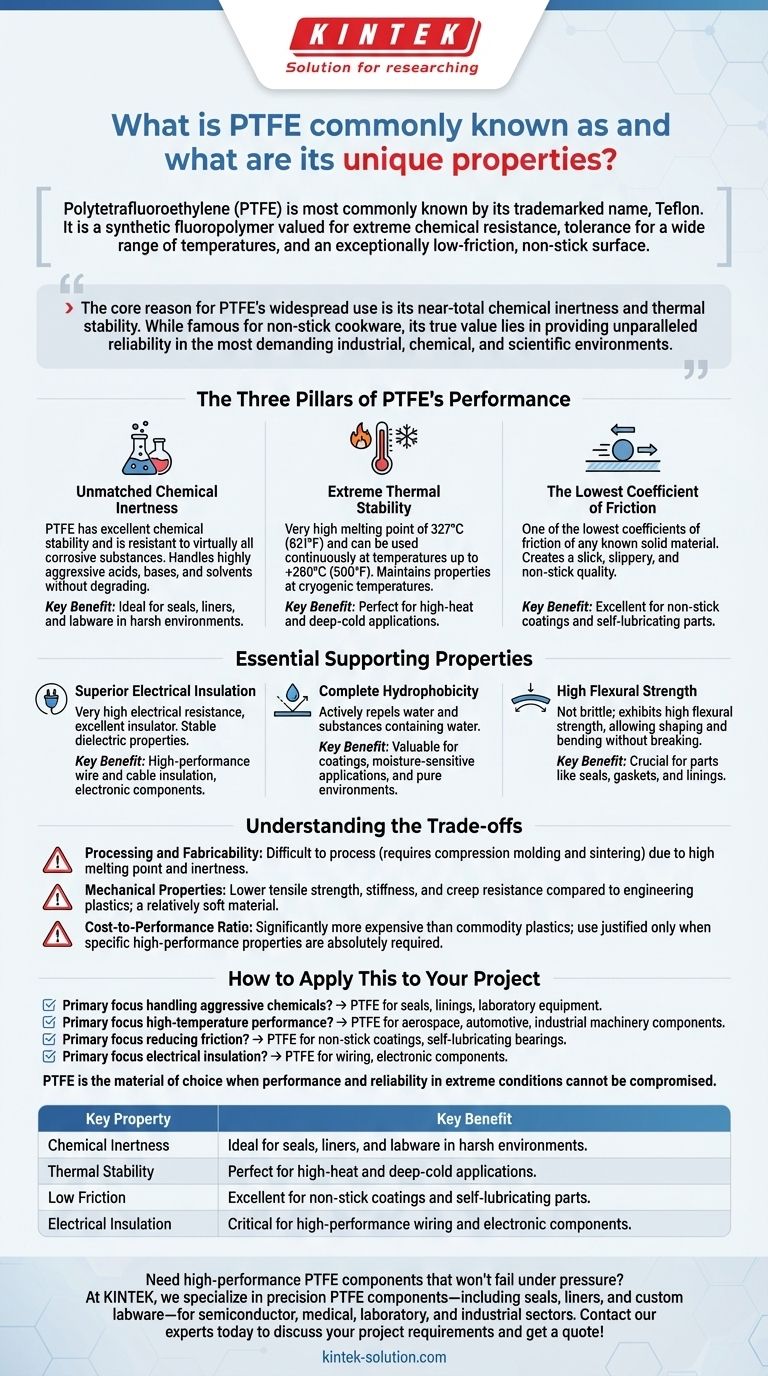

Polytetrafluoroethylene (PTFE) is most commonly known by its trademarked name, Teflon. It is a synthetic fluoropolymer valued for a unique combination of properties, including extreme chemical resistance, tolerance for a wide range of temperatures, and an exceptionally low-friction, non-stick surface.

The core reason for PTFE's widespread use is its near-total chemical inertness and thermal stability. While famous for non-stick cookware, its true value lies in providing unparalleled reliability in the most demanding industrial, chemical, and scientific environments.

The Three Pillars of PTFE's Performance

PTFE's reputation is built on three primary characteristics that set it apart from other polymers. Understanding these is key to understanding its value.

Unmatched Chemical Inertness

PTFE has excellent chemical stability and is resistant to virtually all corrosive substances. It is one of the most corrosion-resistant materials known.

This extreme inertness means it can be used to handle highly aggressive acids, bases, and solvents without degrading. Only hot fluorine gas or certain molten metals are known to affect it.

Extreme Thermal Stability

The material has a very high melting point of 327°C (621°F) and can be used continuously at temperatures up to +260°C (500°F), the highest among all fluoroplastics.

Equally important, PTFE maintains its properties and strength at very low, cryogenic temperatures, making it exceptionally versatile for both high-heat and deep-cold applications.

The Lowest Coefficient of Friction

PTFE has one of the lowest coefficients of friction of any known solid material. This gives it a slick, slippery, and non-stick quality.

This property is not just for cookware; in industrial settings, it is critical for creating self-lubricating bearings, low-friction seals, and coatings for machine parts to reduce wear and energy consumption.

Essential Supporting Properties

Beyond the main three, other characteristics broaden PTFE's range of applications.

Superior Electrical Insulation

PTFE possesses very high electrical resistance, making it an excellent insulator. Its dielectric properties are stable across a wide range of frequencies and temperatures.

This makes it a go-to material for high-performance wire and cable insulation, as well as for components in electrical and electronic devices.

Complete Hydrophobicity

As a fluoropolymer, PTFE is hydrophobic, meaning it actively repels water and substances containing water.

This property is valuable for coatings, moisture-sensitive applications, and use in pure environments like clean rooms or systems using deionized water.

High Flexural Strength

Despite its other properties, PTFE is not brittle. It exhibits high flexural strength, allowing it to be shaped and bent without breaking, which is crucial for parts like seals, gaskets, and linings.

Understanding the Trade-offs

While often called the "king of plastics," PTFE is not the solution for every problem. Its unique strengths come with inherent limitations.

Processing and Fabricability

PTFE's high melting point and chemical inertness make it more difficult to process than common plastics. It cannot be melt-processed using conventional injection molding or extrusion, requiring specialized techniques like compression molding and sintering.

Mechanical Properties

Compared to engineering plastics like nylon or polycarbonate, PTFE has lower tensile strength, stiffness, and creep resistance. It is a relatively soft material, which can be a disadvantage in high-load structural applications.

Cost-to-Performance Ratio

While PTFE offers the best price-to-performance ratio among high-end fluoroplastics, it is significantly more expensive than commodity plastics. Its use is typically justified only when its specific high-performance properties are absolutely required.

How to Apply This to Your Project

Choosing a material requires matching its properties to your primary goal. Use these guidelines to determine if PTFE is the right fit.

- If your primary focus is handling aggressive chemicals: PTFE's near-total inertness makes it the default choice for seals, linings, and laboratory equipment.

- If your primary focus is high-temperature performance: Its continuous stability up to 260°C is critical for components in aerospace, automotive, and industrial machinery.

- If your primary focus is reducing friction: Its exceptionally low coefficient of friction is ideal for creating non-stick coatings and self-lubricating bearings.

- If your primary focus is electrical insulation: Its high dielectric strength is essential for wiring and components in demanding electronic applications.

Ultimately, PTFE is the material of choice when performance and reliability in extreme conditions cannot be compromised.

Summary Table:

| Key Property | Description | Key Benefit |

|---|---|---|

| Chemical Inertness | Resistant to virtually all corrosive chemicals. | Ideal for seals, liners, and labware in harsh environments. |

| Thermal Stability | Stable from cryogenic temps up to +260°C (500°F). | Perfect for high-heat and deep-cold applications. |

| Low Friction | One of the lowest coefficients of friction. | Excellent for non-stick coatings and self-lubricating parts. |

| Electrical Insulation | High dielectric strength and resistance. | Critical for high-performance wiring and electronic components. |

Need high-performance PTFE components that won't fail under pressure?

At KINTEK, we specialize in manufacturing precision PTFE components—including seals, liners, and custom labware—for the semiconductor, medical, laboratory, and industrial sectors. Whether you need prototypes or high-volume orders, our custom fabrication ensures your parts deliver unparalleled chemical resistance, thermal stability, and reliability.

Contact our experts today to discuss your project requirements and get a quote!

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

- Customizable PTFE Rods for Advanced Industrial Applications

- Custom PTFE Volumetric Flasks for Advanced Scientific and Industrial Use

People Also Ask

- What are some common applications of machined PTFE? Leverage its Unique Properties for Demanding Applications

- What are the unique properties of PTFE? Unlock Unmatched Performance in Demanding Applications

- What are the primary applications of PTFE fasteners and custom parts? Critical Solutions for Extreme Environments

- What is the working temperature range of PTFE? Master Extreme Heat and Cryogenic Applications

- What are the base characteristics of PTFE? Unlocking Extreme Performance in Friction, Temperature, and Chemical Resistance