In short, machined PTFE is most commonly used for high-performance seals and gaskets, low-friction bearings and bushings, biocompatible medical devices, and components for handling corrosive chemicals. Its unique combination of properties makes it a go-to material for applications where other polymers would fail due to chemical attack, high temperatures, or friction.

The true value of PTFE isn't in one single characteristic, but in its rare combination of extreme chemical inertness, a remarkably low coefficient of friction, and excellent thermal stability. Understanding which of these properties is most critical for your goal is the key to leveraging this material effectively.

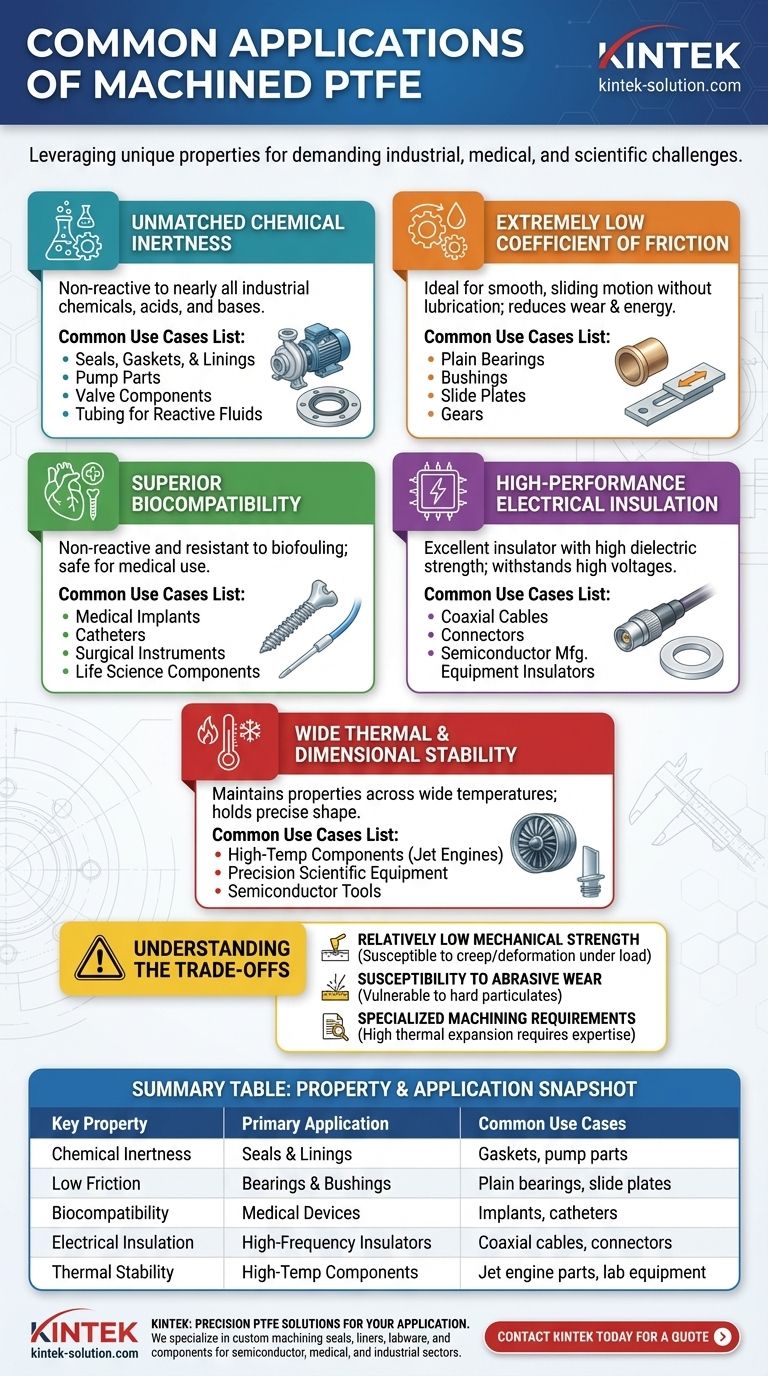

The Core Properties Driving PTFE Adoption

The wide range of applications for machined Polytetrafluoroethylene (PTFE), often known by the brand name Teflon®, stems from a few powerful, interconnected material properties. Each property makes it the ideal choice for a specific set of demanding industrial challenges.

Unmatched Chemical Inertness

PTFE is non-reactive to nearly all industrial chemicals, acids, and bases. This makes it an invaluable material for harsh environments.

This property is why PTFE is specified for seals, gaskets, and linings in chemical processing equipment. It is also machined into pump parts, valve components, and tubing that handle highly reactive or corrosive fluids.

Extremely Low Coefficient of Friction

PTFE has one of the lowest coefficients of friction of any solid material, making it ideal for applications where smooth, sliding motion is required without lubrication.

This leads to its widespread use in plain bearings, bushings, slide plates, and gears. It reduces energy consumption and wear in mechanical systems, often outperforming traditional metal or plastic bearings.

Superior Biocompatibility

The human body does not react to PTFE, and it is highly resistant to biofouling. This makes it a trusted material for medical and life science applications.

It is frequently machined into medical implants, catheters, and surgical instruments. Its non-reactive nature ensures patient safety and device longevity.

High-Performance Electrical Insulation

PTFE is an excellent electrical insulator with a high dielectric strength, meaning it can withstand high voltages without breaking down.

This property makes it essential for insulators in coaxial cables, connectors, and semiconductor manufacturing equipment where signal integrity and electrical isolation are critical.

Wide Thermal and Dimensional Stability

PTFE maintains its properties across a very wide temperature range and has high dimensional stability, meaning it holds its precise shape after machining.

This allows it to be used in high-temperature applications like jet engine components as well as precision scientific and semiconductor equipment where tight tolerances are non-negotiable.

Understanding the Trade-offs of Machined PTFE

While powerful, PTFE is not the solution for every problem. Its unique characteristics come with inherent limitations that are critical to understand before specifying it for a component.

Relatively Low Mechanical Strength

Compared to other engineering plastics like PEEK or nylon, PTFE is quite soft. It has low tensile strength and is susceptible to "creep," or deformation under sustained load.

This makes it unsuitable for high-load structural components unless it is reinforced with fillers like glass fiber or carbon (creating "bearing grades").

Susceptibility to Abrasive Wear

The same softness that contributes to its low friction makes virgin PTFE vulnerable to wear from abrasive particles. It excels in sliding applications but not in environments with hard particulates.

Specialized Machining Requirements

While machinable, PTFE's high rate of thermal expansion and low thermal conductivity require specialized knowledge. Improper machining can induce stress and compromise the dimensional stability of the final part.

Making the Right Choice for Your Application

To determine if machined PTFE is the correct material, you must isolate the primary challenge you are trying to solve.

- If your primary focus is sealing corrosive materials: PTFE is an industry standard for gaskets, O-rings, and valve seats in chemical processing due to its near-universal chemical resistance.

- If your primary focus is reducing friction without lubrication: PTFE is an excellent choice for bearings, bushings, and slide plates where maintenance is difficult and smooth motion is critical.

- If your primary focus is medical or food-grade safety: PTFE's biocompatibility and inertness make it a premier choice for implants, processing equipment, and fluid handling components.

- If your primary focus is high-frequency electrical insulation: PTFE is one of the best materials available for insulators in cables, connectors, and circuit boards due to its low dielectric constant.

By matching the material's core strengths to your application's primary demand, you can confidently engineer a reliable and high-performing solution.

Summary Table:

| Key Property | Primary Application | Common Use Cases |

|---|---|---|

| Chemical Inertness | Seals & Linings | Chemical processing gaskets, pump parts, valve seats |

| Low Friction | Bearings & Bushings | Plain bearings, slide plates, gears |

| Biocompatibility | Medical Devices | Implants, catheters, surgical instruments |

| Electrical Insulation | High-Frequency Insulators | Coaxial cables, connectors, semiconductor equipment |

| Thermal Stability | High-Temp Components | Jet engine parts, precision lab equipment |

Need a high-performance PTFE component for your specialized application?

KINTEK specializes in the precision machining of PTFE seals, liners, labware, and custom components for the semiconductor, medical, laboratory, and industrial sectors. We leverage our deep material expertise to ensure your parts meet the highest standards for chemical resistance, low friction, and thermal stability.

Whether you require a prototype or a high-volume production run, we deliver custom-fabricated solutions that perform reliably in the most demanding environments.

Contact KINTEK today to discuss your project requirements and get a quote.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Customizable PTFE Rods for Advanced Industrial Applications

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

People Also Ask

- How do PTFE and nylon differ in terms of water interactivity? Key Differences for Component Stability

- What are the disadvantages of unreinforced PTFE laminates? Navigating Manufacturing Challenges for High-Frequency Performance

- What are the key properties of PTFE that make it suitable for seals and gaskets? Unlock Superior Sealing Performance

- Are Teflon parts capable of withstanding high temperatures? Understanding the 260°C Limit for Performance

- What are the key properties of PTFE that make it suitable for O-Rings? Unmatched Chemical & Temperature Resistance

- How are glass-filled PTFE rods applied in the automotive industry? Enhance Performance & Reliability

- How is expanded PTFE typically used in flange applications? Solve Leaks on Worn or Damaged Flanges

- What are the physical characteristics of PTFE O-rings? The Ultimate Guide to PTFE Seal Properties