To properly install a PTFE gasket, the process must be viewed as a complete system assembly, not just placing a part. It requires meticulous preparation of the flange surfaces, careful inspection of the gasket, precise alignment, and a highly controlled, multi-stage bolt tightening procedure to create a durable, leak-free seal.

The reliability of a sealed joint depends less on the gasket itself and more on the quality of the installation. A successful seal is the result of clean, aligned surfaces and evenly applied, correct compressive force—anything less invites failure.

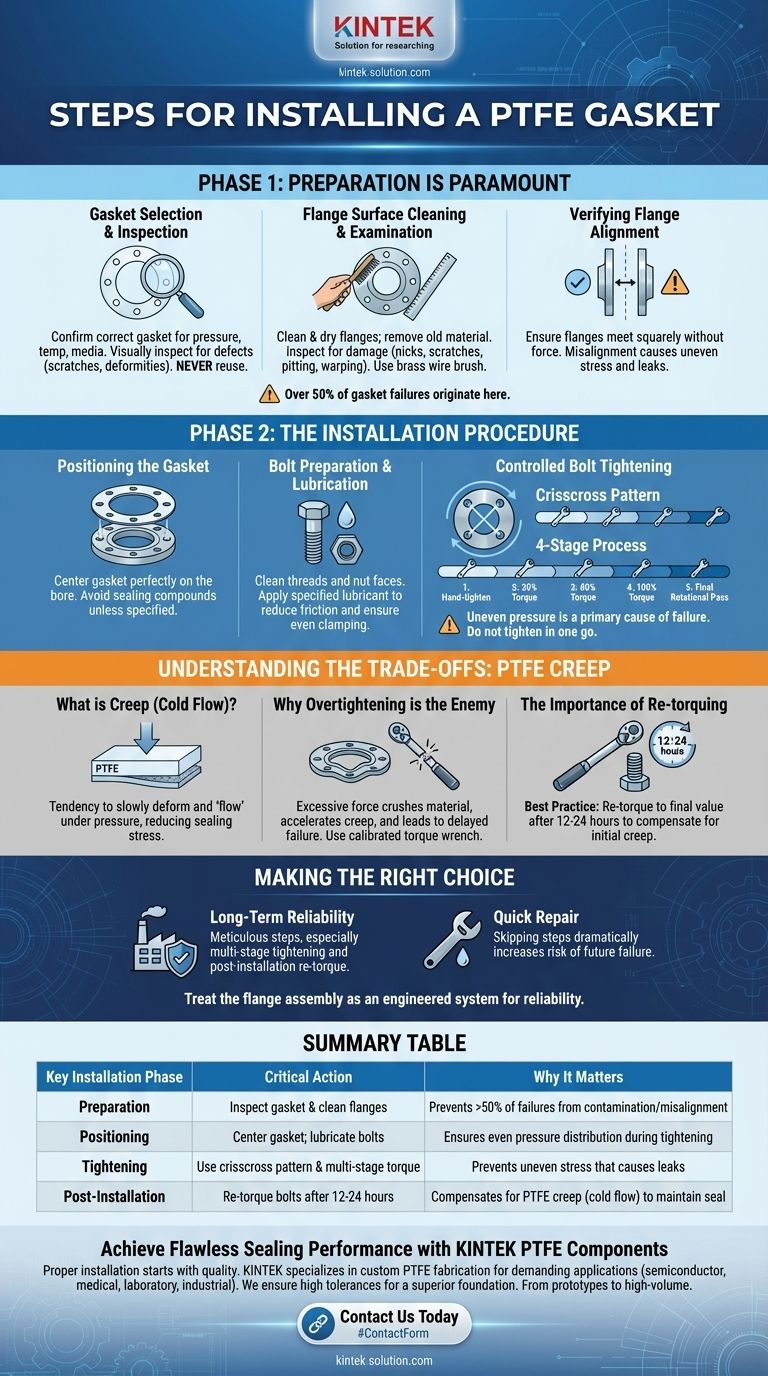

Phase 1: Preparation is Paramount

Before the gasket is even handled, the foundation for a successful seal must be established. Over 50% of gasket failures can be traced back to inadequate preparation of the sealing surfaces.

Gasket Selection and Inspection

First, confirm you have the correct gasket for the application's pressure, temperature, and chemical media. Never reuse a PTFE gasket.

Visually inspect the new gasket for any defects, such as scratches, cuts, or deformities. A compromised gasket will never seal properly and must be discarded.

Flange Surface Cleaning and Examination

The flange faces must be perfectly clean, dry, and free of any old gasket material, rust, or other contaminants. Use a wire brush (brass is preferred to avoid scratching the surface) and an appropriate solvent.

Critically, inspect the clean flange surfaces for damage. Run a finger or a straight edge across the face to feel for nicks, deep scratches, pitting, or warping. No gasket can reliably seal a damaged flange.

Verifying Flange Alignment

Ensure the flanges can be brought together squarely without force. Misalignment, whether angular or parallel, places uneven stress on the gasket and will cause a leak.

If you must pull on pipes to bring the flanges together, the underlying piping issue must be corrected first.

Phase 2: The Installation Procedure

With the flanges fully prepared, the installation can begin. Each step must be performed with precision.

Positioning the Gasket

Carefully place the gasket on the flange face, ensuring it is perfectly centered on the bore. Do not use any sealing compound or grease unless explicitly specified by the manufacturer, as this can interfere with the gasket's function.

Bolt Preparation and Lubrication

Ensure all bolt threads and nut faces are clean. Apply a small amount of a specified, high-quality lubricant to the bolt threads and the face of the nut that will contact the flange.

Lubrication is not for sealing; it is to reduce friction during tightening. This ensures that the applied torque translates into consistent, even clamping force on the gasket.

Controlled Bolt Tightening

This is the most critical step. Uneven pressure is a primary cause of gasket failure. Always tighten bolts using a crisscross pattern to apply pressure evenly across the gasket surface.

Do not tighten the bolts to their final torque in one go. The process must be done in stages:

- Hand-tighten all bolts.

- First Pass: Tighten each bolt to approximately 30% of the final target torque.

- Second Pass: Tighten each bolt to approximately 60% of the final target torque.

- Final Pass: Tighten each bolt to 100% of the final target torque.

- Rotational Pass: Perform one final pass, moving sequentially from one bolt to the next, to verify all bolts are at the final torque value.

Understanding the Trade-offs: The Challenge of PTFE Creep

PTFE is an exceptional sealing material, but its primary weakness must be managed: its tendency to "creep."

What is Creep (Cold Flow)?

Creep, also known as cold flow, is the tendency of PTFE to slowly deform and "flow" away from the point of pressure over time. This relaxation reduces the stress on the gasket and can lead to a loss of sealing pressure.

Why Overtightening is the Enemy

It's tempting to overtighten a gasket to ensure a tight seal, but with PTFE, this is counterproductive. Excessive clamping force crushes the material's structure, accelerates creep, and can cause the seal to fail hours or days after installation.

You must use a calibrated torque wrench and adhere to the manufacturer's specified torque values for your specific gasket and flange class.

The Importance of Re-torquing

Because of creep, the initial bolt load will decrease after installation. It is a best practice to re-torque the bolts to their final specified value approximately 12 to 24 hours after the initial installation. This compensates for initial creep and ensures a stable, long-term seal.

Making the Right Choice for Your Goal

Your approach to installation determines the reliability and lifespan of the sealed joint.

- If your primary focus is long-term reliability and plant safety: Follow every step meticulously, especially controlled, multi-stage tightening and the post-installation re-torque to manage PTFE creep.

- If your primary focus is a quick repair to stop a leak: Understand that skipping surface preparation or using improper tightening techniques dramatically increases the risk of a more severe failure in the near future.

By treating the entire flange assembly as an engineered system, you transform gasket installation from a simple task into a reliable and repeatable process.

Summary Table:

| Key Installation Phase | Critical Action | Why It Matters |

|---|---|---|

| Preparation | Inspect gasket & clean flanges | Prevents >50% of failures from contamination/misalignment |

| Positioning | Center gasket; lubricate bolts | Ensures even pressure distribution during tightening |

| Tightening | Use crisscross pattern & multi-stage torque | Prevents uneven stress that causes leaks |

| Post-Installation | Re-torque bolts after 12-24 hours | Compensates for PTFE creep (cold flow) to maintain seal |

Achieve Flawless Sealing Performance with KINTEK PTFE Components

Proper installation is critical, but it starts with a high-quality, precision-manufactured gasket. KINTEK specializes in custom PTFE fabrication for demanding applications in the semiconductor, medical, laboratory, and industrial sectors.

We ensure our PTFE seals, liners, and labware are manufactured to the highest tolerances, providing a superior foundation for your critical sealing processes. Whether you need prototypes or high-volume orders, our expertise guarantees a component that performs reliably from the moment it's installed.

Contact us today to discuss your specific requirements and let our precision solutions enhance your system's reliability.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Customizable PTFE Seals Filter Holders for Versatile Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Customizable PTFE Rods for Advanced Industrial Applications

People Also Ask

- Why are expanded PTFE gaskets considered a reliable sealing solution? Achieve Leak-Free Performance in Demanding Environments

- What materials are used in PTFE slide bearing plates? Choose the Right Bearing for Your Application

- How can PTFE rotary shaft seals contribute to operational efficiency and cost savings? Maximize Uptime & Reduce Costs

- How does the corrosion resistance of Teflon gland fillers benefit chemical industry applications? Ensuring Safety and Reliability

- How might nanotechnology improve PTFE seal performance? Achieve Unmatched Durability and Efficiency

- Why are PTFE O-rings suitable for high-temperature applications? Unmatched Thermal & Chemical Stability

- What are some common applications of filled PTFE? Enhance Performance in Demanding Industries

- How often should a PTFE coating thrust washer be replaced? Proactive Maintenance for Peak Performance