In addition to standard elastomeric bearing tests, PTFE sliding rubber bearings undergo three critical tests specifically for the Polytetrafluoroethylene (PTFE) plate. These are the loading test, the friction coefficient test, and the wear resistance test. These evaluations are essential to verify the bearing's ability to facilitate controlled movement while supporting immense structural loads.

The specific tests for PTFE are not merely procedural checks; they are the validation process for a highly customized engineering solution. They ensure the bearing can safely manage the unique loads and movements of a specific project, often under tight physical and design constraints.

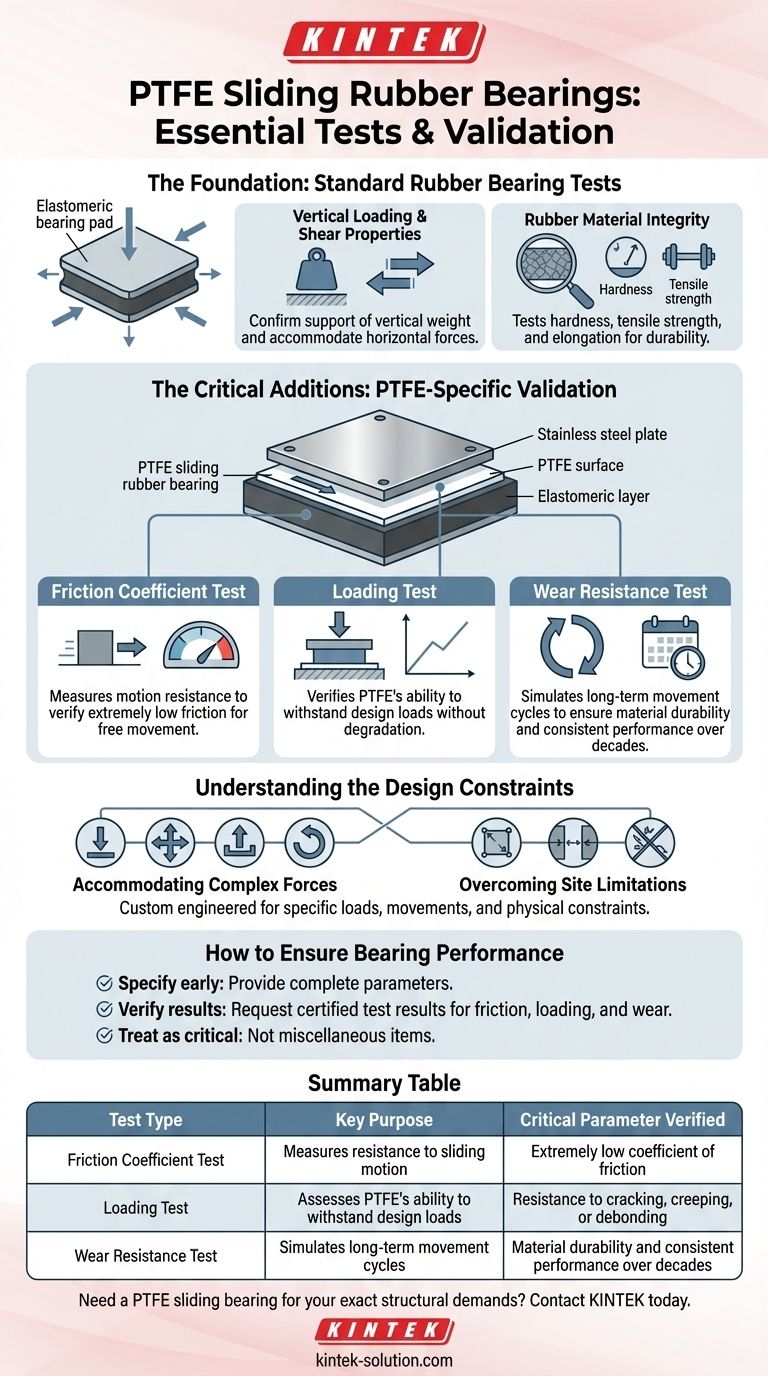

The Foundation: Standard Rubber Bearing Tests

Before addressing the unique aspects of PTFE, it's important to recognize that these components are built upon the foundation of a standard elastomeric bearing. Therefore, they must first pass the baseline tests required for any structural rubber bearing.

Vertical Loading and Shear Properties

These fundamental tests confirm the rubber's ability to support the vertical weight of the superstructure without excessive bulging or failure. Shear tests verify that the bearing can accommodate horizontal forces and movements through the deformation of its internal rubber layers.

Rubber Material Integrity

The raw elastomeric material itself is tested for properties like hardness, tensile strength, and elongation. This ensures the material meets the quality and durability standards required for the projected lifespan of the structure.

The Critical Additions: PTFE-Specific Validation

The addition of a PTFE sliding surface fundamentally changes the bearing's function, necessitating a distinct set of performance tests. These focus on the interaction between the PTFE and the mating stainless steel plate.

The Friction Coefficient Test

This is arguably the most critical test for a sliding bearing. It measures the resistance to motion between the PTFE surface and its corresponding stainless steel plate under a specified load.

The goal is to verify an extremely low coefficient of friction. This ensures the superstructure can move freely (e.g., due to thermal expansion) without transferring damaging stresses to the substructure.

The Loading Test

While the elastomeric pad is tested for vertical load, the PTFE plate itself must also be tested. This process verifies that the PTFE layer can withstand the specified design loads without cracking, creeping, or debonding from the bearing.

The Wear Resistance Test

Durability is paramount. This test simulates the long-term effects of repeated movement cycles on the PTFE surface. It confirms that the plate can endure thousands of movements over its service life without significant material degradation, ensuring consistent performance for decades.

Understanding the Design Constraints

The rigor of these tests is a direct result of the complex problems PTFE sliding bearings are designed to solve. They are not off-the-shelf parts but custom components engineered for specific, often challenging, conditions.

Accommodating Complex Forces

Manufacturers design these bearings based on a precise set of client parameters. These include not just vertical load and longitudinal movement, but also lateral movement, potential uplift loads, and rotational demands. The testing protocol validates that the final product can handle this multi-directional reality.

Overcoming Site Limitations

Often, bearings are considered late in the design process when physical constraints are already set. Limited space, predefined gaps between the superstructure and substructure, and restrictions on welding or bolting demand highly customized solutions.

This reality makes PTFE sliding bearings a premium product. Each one is tailored to its unique application, and the tests serve as the final verification that the custom design is feasible and effective.

How to Ensure Bearing Performance

Your approach to these components will dictate their success. The focus should always be on clarity in the design phase and diligence in the verification stage.

- If your primary focus is specifying a new bearing: Provide the manufacturer with complete and accurate design parameters—including all loads, movements, and rotations—as early as possible.

- If your primary focus is verifying a supplied bearing: Request the certified test results for the friction coefficient, loading, and wear resistance tests to ensure the product meets your project's explicit performance requirements.

- If your primary focus is project management: Treat bearings as critical structural components from day one, not as miscellaneous items to be finalized at the last minute.

Properly specifying and verifying a PTFE sliding bearing ensures it functions as a critical engineering solution, safeguarding the long-term integrity and safety of your structure.

Summary Table:

| Test Type | Key Purpose | Critical Parameter Verified |

|---|---|---|

| Friction Coefficient Test | Measures resistance to sliding motion | Extremely low coefficient of friction |

| Loading Test | Assesses PTFE's ability to withstand design loads | Resistance to cracking, creeping, or debonding |

| Wear Resistance Test | Simulates long-term movement cycles | Material durability and consistent performance over decades |

Need a PTFE sliding bearing that meets your project's exact structural demands? At KINTEK, we specialize in manufacturing high-precision PTFE components, including custom seals, liners, and labware for the semiconductor, medical, laboratory, and industrial sectors. Our expertise in custom fabrication—from prototypes to high-volume orders—ensures your bearing is precision-engineered to handle complex loads and movements. Contact us today to discuss your specific requirements and ensure your structure's long-term integrity and safety.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- PTFE Chemical Solvent Sampling Spoon

People Also Ask

- What are the best practices for achieving tight tolerances in Teflon (PTFE) machining? Master Precision for Demanding Applications

- What industries use PTFE machined parts and for what applications? Critical Components for Demanding Environments

- What are the key considerations when machining Teflon? Master Precision Machining for Soft Polymers

- What are the main advantages of using PTFE parts in industrial applications? Unlock Unmatched Chemical Resistance and Reliability

- What are the future considerations for machining Teflon? Mastering Material Challenges with Smart Tech