In sewing and fabric crafts, a Teflon (PTFE) sheet serves as an indispensable, reusable protective barrier for any task involving heat or sticky materials. It excels as a pressing cloth for delicate fabrics and is essential for preventing materials like heat transfer vinyl, adhesives, or synthetic leathers from sticking to your iron or heat press, ensuring a clean and professional result.

The core problem in many advanced sewing projects is managing intense heat and friction. A Teflon sheet solves this by acting as a thermal and physical shield, protecting both your delicate project from damage and your expensive tools from residue.

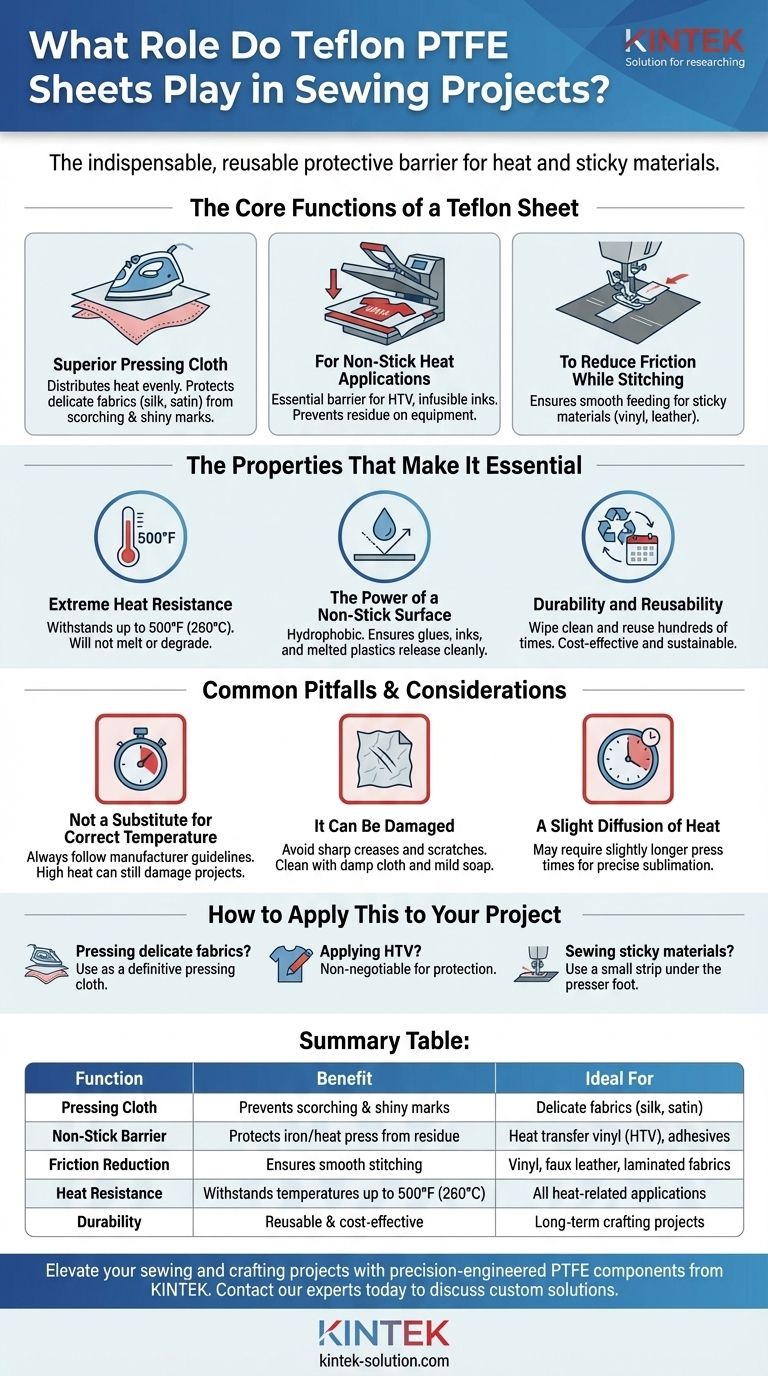

The Core Functions of a Teflon Sheet

A Teflon sheet isn't a single-purpose tool; its value comes from its versatility in solving several common frustrations in sewing and fabric crafting.

As a Superior Pressing Cloth

When ironing delicate fabrics like silk, satin, or certain synthetics, direct contact with a hot iron can cause scorching, melting, or unsightly shiny marks. A Teflon sheet distributes the heat evenly and creates a protective layer, allowing you to press these materials safely at the required temperature.

For Non-Stick Heat Applications

This is the sheet's most critical role. When applying heat transfer vinyl (HTV), infusible inks, or other adhesives, a Teflon sheet acts as a non-stick barrier between your project and your heat source. This prevents any excess vinyl, ink, or melted adhesive from sticking to the hot platen of your heat press or the soleplate of your iron.

To Reduce Friction While Stitching

The non-stick, low-friction surface is also useful during the actual sewing process. When stitching materials like vinyl, faux leather, or laminated cotton, the presser foot can drag and stick, leading to uneven stitches. Placing a small piece of a Teflon sheet under the presser foot allows it to glide effortlessly over the material.

The Properties That Make It Essential

The effectiveness of Teflon sheets comes from a unique combination of material properties that are perfectly suited for textile work.

Extreme Heat Resistance

PTFE sheets can typically withstand temperatures up to 500°F (260°C). This is well above the range used for most fabric and heat transfer applications, meaning the sheet will not melt, burn, or degrade under your iron or heat press.

The Power of a Non-Stick Surface

The defining feature of Teflon is its non-stick (hydrophobic) surface. This property is what ensures that glues, inks, and melted plastics release cleanly from the sheet, protecting your equipment and preventing messy transfers onto your project.

Durability and Reusability

Unlike disposable materials like parchment paper, a high-quality Teflon sheet can be wiped clean and reused for hundreds or even thousands of presses. This makes it both cost-effective and a more sustainable choice for your workshop.

Common Pitfalls and Considerations

While incredibly useful, a Teflon sheet is a tool that must be used correctly to be effective.

It Is Not a Substitute for Correct Temperature

A Teflon sheet protects from direct contact and residue, but it cannot save your project from a fundamentally incorrect temperature setting. If your heat is set too high for the fabric or vinyl, you can still damage your project. Always follow the manufacturer's guidelines.

It Can Be Damaged

The sheet's non-stick properties rely on an intact surface. Avoid creasing the sheet sharply or scratching it with sharp tools. For cleaning, simply wipe it down with a damp cloth; use mild soap and water only for stubborn residue.

A Slight Diffusion of Heat

The sheet adds a thin layer between the heat source and the project. In most cases, this is negligible, but for highly precise sublimation or specialty vinyl, you may need to add a few extra seconds to your press time to compensate for this thermal barrier.

How to Apply This to Your Project

Your specific goal will determine how you use this versatile tool.

- If your primary focus is pressing delicate fabrics: Use the sheet as a definitive pressing cloth to prevent scorching and shiny marks on materials like silk or rayon.

- If your primary focus is applying heat transfer vinyl (HTV): The sheet is non-negotiable for protecting your design and your heat press from melted adhesive and ink.

- If your primary focus is sewing "sticky" materials: A small strip of a Teflon sheet can solve frustrating feeding issues caused by friction between the presser foot and fabrics like vinyl or leather.

Ultimately, incorporating a Teflon sheet into your workflow is a simple step that significantly elevates the quality and consistency of your finished projects.

Summary Table:

| Function | Benefit | Ideal For |

|---|---|---|

| Pressing Cloth | Prevents scorching & shiny marks | Delicate fabrics (silk, satin) |

| Non-Stick Barrier | Protects iron/heat press from residue | Heat transfer vinyl (HTV), adhesives |

| Friction Reduction | Ensures smooth stitching | Vinyl, faux leather, laminated fabrics |

| Heat Resistance | Withstands temperatures up to 500°F (260°C) | All heat-related applications |

| Durability | Reusable & cost-effective | Long-term crafting projects |

Elevate your sewing and crafting projects with precision-engineered PTFE components from KINTEK.

Whether you're a hobbyist creating intricate designs or a professional in the textile industry requiring reliable, high-performance materials, our custom-fabricated PTFE sheets and components are designed to meet your exact needs. We specialize in manufacturing durable, heat-resistant PTFE solutions that ensure flawless results and protect your valuable equipment.

Let us help you achieve perfection in every project. Contact our experts today to discuss custom solutions, from prototypes to high-volume orders.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Square Trays for Industrial and Laboratory Use

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Teflon Balls for Advanced Industrial Applications

People Also Ask

- What are the key advantages of PTFE lined butterfly valves? Superior Chemical Resistance & Cost Savings

- Why is the high-temperature tolerance of PTFE gaskets important? Ensure Reliable Sealing in Extreme Heat

- What are the properties and uses of bronze-filled PTFE? A Guide to High-Performance Mechanical Components

- What are the future development trends for PTFE seal technology? Advanced Materials & Precision Manufacturing

- What are the main challenges when machining Teflon (PTFE)? Overcome Softness, Heat, and Precision Issues

- What techniques help minimize material smearing during Teflon machining? Achieve Clean, Precise PTFE Parts

- How do PTFE slide bearings compare in load capacity to traditional bearings? Superior Support for High-Load, Low-Speed Applications

- What are the material properties of PTFE relevant to CNC machining? Mastering Softness & Heat for Precision