At its core, a PTFE-lined butterfly valve offers a unique combination of extreme chemical inertness, a wide operational temperature range, and excellent sealing capabilities. This is achieved by isolating the process fluid from the valve's body and stem, allowing a more cost-effective body material to be used while the PTFE liner provides superior protection against corrosion and contamination.

The true advantage of a PTFE-lined butterfly valve is not just its material properties, but its design philosophy: it leverages the structural strength of a standard valve body with the near-universal chemical and thermal resilience of a high-performance polymer, delivering exceptional performance at a lower cost than exotic alloy alternatives.

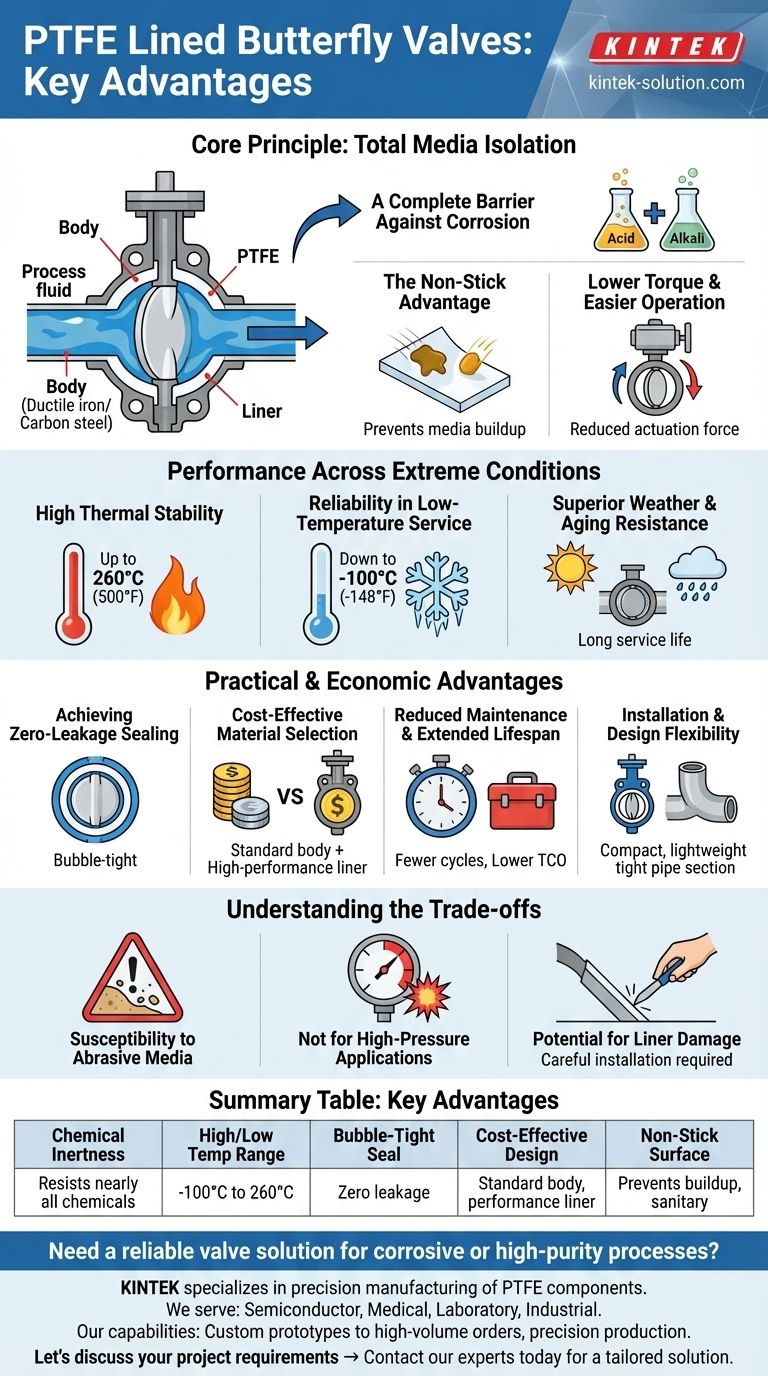

The Core Principle: Total Media Isolation

The primary function of the PTFE liner is to create an impermeable barrier, ensuring that the process media only ever comes into contact with the chemically inert Polytetrafluoroethylene (PTFE).

A Complete Barrier Against Corrosion

PTFE is renowned for its resistance to nearly all industrial chemicals, including strong acids, alkalis, and powerful oxidants. By lining the valve body and encapsulating the disc, the valve's structural components are completely shielded from corrosive attack.

The Non-Stick Advantage

PTFE has one of the lowest coefficients of friction of any solid material. This non-stick surface prevents media from building up or adhering to the valve's internal parts, which is critical in sanitary applications or processes with sticky substances.

Lower Torque and Easier Operation

The low-friction surface means the valve disc rotates with less resistance against the seat. This reduces the torque required for actuation, allowing for smaller, less expensive actuators and making manual operation significantly easier.

Performance Across Extreme Conditions

PTFE-lined valves are not limited to standard chemical applications. Their material properties give them a distinct advantage in systems with fluctuating or extreme temperatures.

High Thermal Stability

These valves can reliably operate at high temperatures, with most designs rated for continuous service up to 200°C (392°F) and with some capable of handling excursions up to 260°C (500°F).

Reliability in Low-Temperature Service

Unlike many materials that become brittle at low temperatures, PTFE retains its flexibility and softness. This makes it suitable for applications down to -100°C (-148°F), ensuring a reliable seal even in cryogenic conditions.

Superior Weather and Aging Resistance

PTFE is virtually unaffected by UV radiation and weathering. This inherent durability translates to a long service life and minimal material degradation, even when installed outdoors or in harsh environments.

Practical and Economic Advantages

Beyond its technical performance, the design of a PTFE-lined butterfly valve offers significant benefits related to cost, maintenance, and system design.

Achieving Zero-Leakage Sealing

The soft, resilient nature of the PTFE seat allows it to create an exceptionally tight bubble-tight seal around the disc. This high sealing performance is critical for preventing leaks of hazardous materials and ensuring process efficiency.

Cost-Effective Material Selection

Because the liner protects the valve body, you can often use a less expensive body material, such as ductile iron or carbon steel, instead of a costly full stainless steel or exotic alloy valve. This provides significant cost savings without compromising chemical compatibility.

Reduced Maintenance and Extended Lifespan

The combination of corrosion resistance, a non-stick surface, and durability means less wear and tear on valve components. This results in fewer maintenance cycles and a longer overall lifespan, reducing the total cost of ownership.

Installation and Design Flexibility

Butterfly valves are inherently lightweight and compact compared to other valve types like gate or globe valves. This makes them easier to install, especially in tight spaces, and offers greater flexibility in piping system design.

Understanding the Trade-offs

No valve is a universal solution. Being a trusted advisor means acknowledging the limitations of this design.

Susceptibility to Abrasive Media

PTFE is a relatively soft material. It is not recommended for services with abrasive slurries or hard particulates, as these can quickly erode the liner and compromise the valve's integrity.

Not for High-Pressure Applications

While excellent for many industrial uses, PTFE-lined valves generally have lower pressure ratings than metal-seated butterfly valves. Exceeding these pressure-temperature limits can deform the liner and cause the seal to fail.

Potential for Liner Damage

The integrity of the valve depends entirely on the liner. Care must be taken during installation to avoid scratching or gouging the PTFE, as any damage can create a leak path and lead to premature failure of the valve body.

Making the Right Choice for Your Application

Selecting the correct valve requires matching its strengths to your operational goals.

- If your primary focus is handling highly corrosive media: The PTFE liner provides an excellent, cost-effective barrier against acids, caustics, and other aggressive chemicals.

- If your primary focus is high-purity or food-grade processes: The non-stick, inert surface of PTFE prevents contamination and media buildup, ensuring product integrity.

- If your primary focus is high-pressure or abrasive slurry service: A metal-seated butterfly valve or a valve with a harder lining material would be a more suitable choice.

- If your primary focus is cost-effective general-purpose valving: The ability to use a standard body material with a high-performance liner makes this a very economical option for a wide range of applications.

Understanding these core strengths and limitations ensures you are choosing a component that delivers long-term reliability and safety for your specific system.

Summary Table:

| Key Advantage | Description |

|---|---|

| Chemical Inertness | Resists nearly all industrial chemicals, including strong acids and alkalis. |

| High/Low Temp Range | Operates from -100°C to 260°C (-148°F to 500°F). |

| Bubble-Tight Seal | Ensures zero leakage for hazardous or high-purity processes. |

| Cost-Effective Design | Uses a standard body material protected by the PTFE liner, lowering cost. |

| Non-Stick Surface | Prevents media buildup, ideal for sanitary and sticky substance applications. |

Need a reliable valve solution for corrosive or high-purity processes?

At KINTEK, we specialize in precision manufacturing of PTFE components, including custom-fabricated liners and seals for critical applications. Our expertise ensures your valves deliver maximum chemical resistance, longevity, and performance.

We serve: Semiconductor, Medical, Laboratory, Industrial, and other specialized industries.

Our capabilities: From custom prototypes to high-volume orders, we prioritize precision production to meet your exact specifications.

Let's discuss your project requirements → Contact our experts today for a tailored solution.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

- Customizable PTFE Seals Filter Holders for Versatile Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

People Also Ask

- How does the design of PTFE lined butterfly valves improve performance? Achieve Superior Corrosion Resistance & Zero Leakage

- What materials are available for guide rings and what are their properties? Select the Right Compound for Your Application

- What makes glass-filled PTFE rods suitable for electrical connectors? Superior Insulation & Durability

- How does graphite-filled PTFE improve sealing performance? Enhance Wear Resistance & Self-Lubrication

- What are the longevity and durability benefits of PTFE gaskets? Achieve Reliable, Long-Lasting Sealing Performance

- How does the low friction property of PTFE benefit sealing applications? Achieve Reliable, Low-Stress Seals

- What is a potential drawback of using stainless steel filler in PTFE? Balancing Durability and System Wear

- What is PTFE and what makes it suitable for sealing applications? Solve Extreme Sealing Challenges