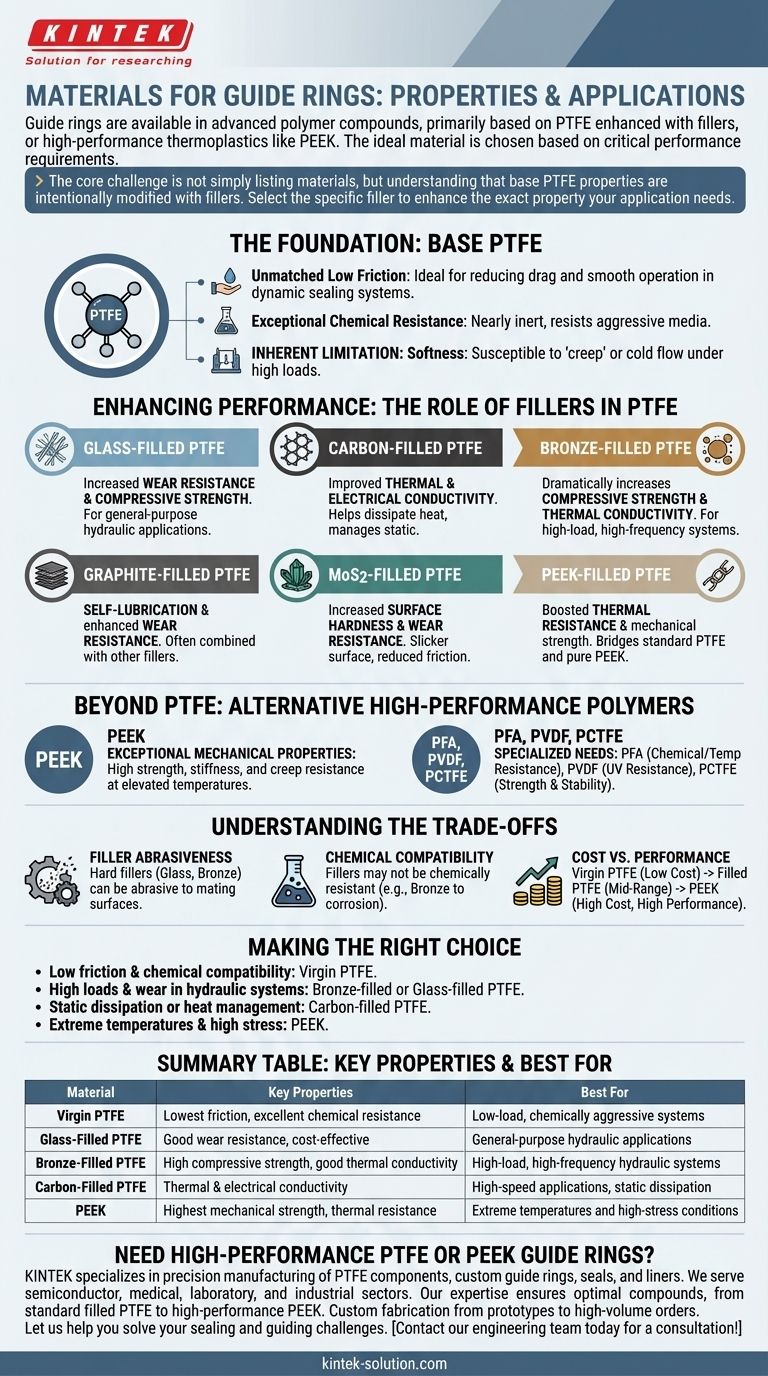

Guide rings are available in a range of advanced polymer compounds, primarily based on PTFE (Polytetrafluoroethylene) enhanced with various fillers. Other high-performance thermoplastics like PEEK are also used for more demanding applications. The ideal material is chosen by identifying the critical performance requirement—such as wear resistance, load capacity, or chemical inertness—and selecting the compound engineered to excel in that specific area.

The core challenge is not simply listing materials, but understanding that the base properties of a polymer like PTFE are intentionally modified with fillers. Your goal is to select the specific filler that enhances the exact property your application needs to improve, such as wear resistance or thermal conductivity.

The Foundation: Understanding Base PTFE

Polytetrafluoroethylene, or PTFE, is the starting point for many guide ring materials due to a unique combination of properties. It sets the baseline for performance.

Unmatched Low Friction

PTFE has one of the lowest coefficients of friction of any solid material. This makes it an ideal choice for reducing drag and ensuring smooth operation in dynamic sealing systems.

Exceptional Chemical Resistance

This material is nearly inert, resisting almost all industrial chemicals and solvents. This broad compatibility makes it a safe choice for systems with aggressive media.

The Inherent Limitation: Softness

The primary drawback of virgin PTFE is its relative softness. Under high loads, it is susceptible to "creep" or cold flow, which can lead to dimensional changes and reduced effectiveness over time.

Enhancing Performance: The Role of Fillers in PTFE

To overcome the softness of virgin PTFE and improve specific mechanical properties, various fillers are blended into the base material. Each filler provides a distinct advantage.

For General-Purpose Wear Resistance: Glass-Filled PTFE

Adding glass fibers significantly increases wear resistance and compressive strength. This is a very common and cost-effective choice for improving durability in standard hydraulic applications.

For Thermal and Electrical Conductivity: Carbon-Filled PTFE

Carbon improves thermal conductivity, helping to dissipate heat in high-speed applications. It also provides electrical conductivity, making it suitable for applications where static electricity must be managed.

For High Loads and Thermal Transfer: Bronze-Filled PTFE

Bronze powder is a popular filler that dramatically increases compressive strength and thermal conductivity. It is excellent for high-load, high-frequency hydraulic systems but is not suitable for contact with corrosive fluids or soft shafts.

For Self-Lubrication: Graphite-Filled PTFE

Graphite is a dry lubricant that enhances the already low friction of PTFE. It also improves wear resistance and is often combined with other fillers like carbon.

For Increased Hardness: Molybdenum Disulphide (MoS2) Filled PTFE

MoS2 is another lubricant that increases the material's surface hardness and wear resistance. It results in a slicker surface, further reducing friction.

For High-Temperature Applications: PEEK-Filled PTFE

Adding PEEK (Polyetheretherketone) as a filler substantially boosts the thermal resistance and mechanical strength of PTFE, bridging the gap between standard PTFE compounds and pure PEEK.

Beyond PTFE: Alternative High-Performance Polymers

For applications where even filled PTFE is insufficient, other engineering polymers offer superior mechanical performance, though often at a higher cost.

When Mechanical Strength is Paramount: PEEK

PEEK offers exceptional mechanical properties, including high strength, stiffness, and creep resistance, even at elevated temperatures. It is a premium choice for the most demanding operating conditions.

For Specialized Needs: PFA, PVDF, and PCTFE

These polymers offer unique benefits. PFA has chemical and temperature resistance similar to PTFE but with better mechanical properties. PVDF provides excellent UV resistance for outdoor applications, while PCTFE offers a good balance of mechanical strength and chemical stability.

Understanding the Trade-offs

Selecting a material is always an exercise in balancing competing factors. No single compound is perfect for every situation.

Filler Abrasiveness

Hard fillers like glass and bronze significantly improve wear resistance but can be abrasive to softer shaft or bore materials. Always consider the hardness of mating surfaces when selecting a filled compound.

Chemical Compatibility

While PTFE is nearly universally resistant, the fillers are not. Bronze, for example, is susceptible to corrosion. You must ensure the filler material is compatible with your system's media.

Cost vs. Performance

There is a clear cost hierarchy. Virgin PTFE is the most economical, common filled compounds are in the mid-range, and high-performance polymers like PEEK represent a significant cost increase justified only by extreme application demands.

Making the Right Choice for Your Application

Your final selection should be driven by the most critical demand of your system.

- If your primary focus is low friction and broad chemical compatibility: Virgin PTFE is often sufficient for low-load applications.

- If you need to manage high loads and wear in standard hydraulic systems: Bronze-filled or glass-filled PTFE are industry-standard choices.

- If you require static dissipation or heat management in high-speed systems: Carbon-filled PTFE is the optimal selection.

- If your system operates at extreme temperatures and under high mechanical stress: PEEK offers the ultimate level of performance.

Selecting the right material is a matter of precisely matching the polymer's properties to the unique demands of your system.

Summary Table:

| Material | Key Properties | Best For |

|---|---|---|

| Virgin PTFE | Lowest friction, excellent chemical resistance | Low-load, chemically aggressive systems |

| Glass-Filled PTFE | Good wear resistance, cost-effective | General-purpose hydraulic applications |

| Bronze-Filled PTFE | High compressive strength, good thermal conductivity | High-load, high-frequency hydraulic systems |

| Carbon-Filled PTFE | Thermal & electrical conductivity | High-speed applications, static dissipation |

| PEEK | Highest mechanical strength, thermal resistance | Extreme temperatures and high-stress conditions |

Need High-Performance PTFE or PEEK Guide Rings?

KINTEK specializes in the precision manufacturing of PTFE components, including custom guide rings, seals, and liners. We serve the semiconductor, medical, laboratory, and industrial sectors.

We understand that selecting the right material is critical to your system's performance and longevity. Our expertise ensures you get the optimal compound—whether it's standard filled PTFE or high-performance PEEK—perfectly matched to your application's demands for wear, load, and chemical resistance.

We offer custom fabrication from prototypes to high-volume orders, ensuring you receive components built to your exact specifications.

Let us help you solve your sealing and guiding challenges. Contact our engineering team today for a consultation!

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Customizable PTFE Rods for Advanced Industrial Applications

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

People Also Ask

- What are the unique properties of PTFE? The 3 Pillars Driving Demand for High-Performance Parts

- What chemical processing applications involve PTFE-machined parts? Essential Components for Corrosive & High-Purity Systems

- What finishing techniques are effective for machined Teflon parts? Achieve Functional Performance and Dimensional Stability

- What are the unique properties of PTFE? Unlock Unmatched Performance in Demanding Applications

- What challenges arise when machining PTFE (Teflon)? Overcome Softness, Heat, and Instability