At its core, the design of a PTFE-lined butterfly valve improves performance by using a chemically inert and non-stick Polytetrafluoroethylene (PTFE) layer to completely isolate the valve's metal body and components from the process media. This creates a powerful hybrid, combining the structural strength and rigidity of a metal valve with the exceptional resistance of PTFE, solving common issues of corrosion, leakage, and operational friction.

The central advantage is not just adding a layer of protection, but fundamentally combining two materials to create a valve that leverages the best properties of both: the mechanical strength of metal and the near-universal chemical and thermal resilience of PTFE.

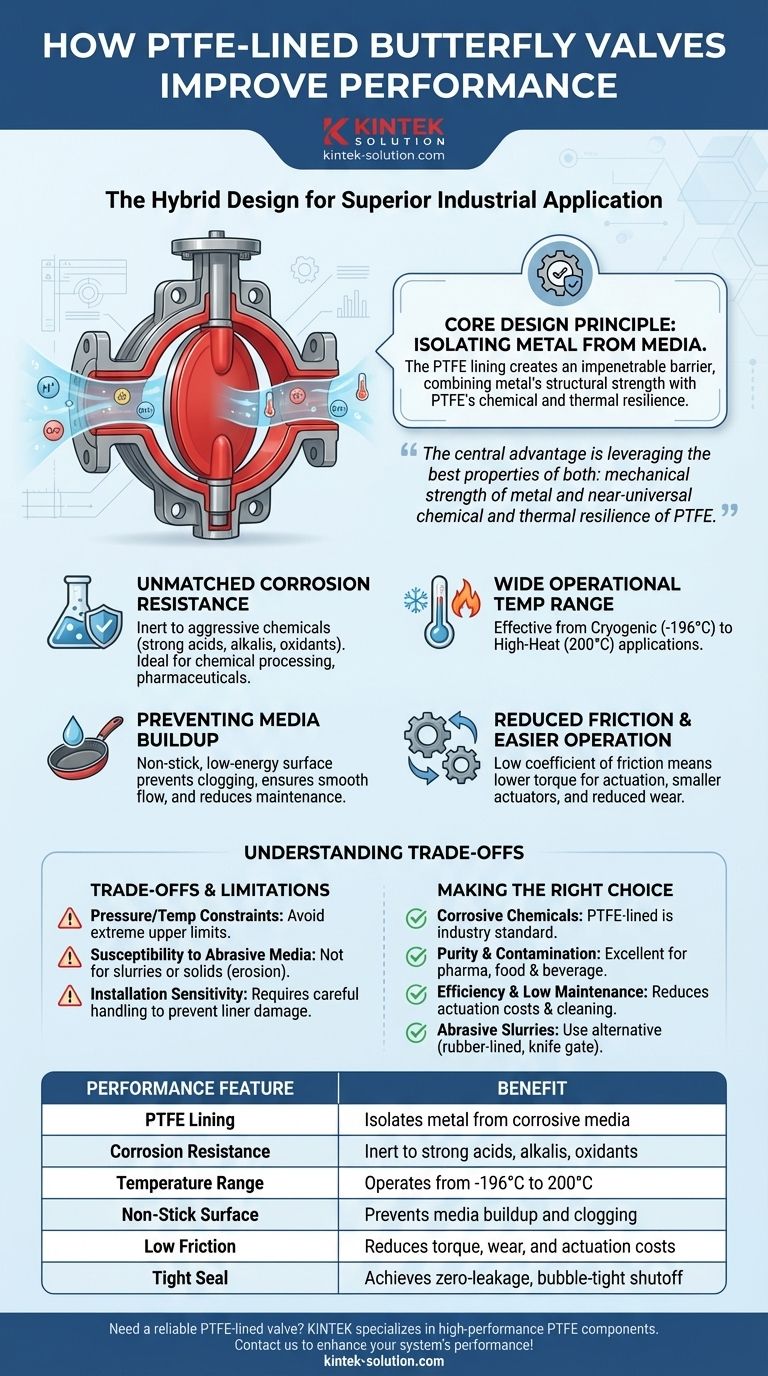

The Core Design Principle: Isolating Metal from Media

The primary function of the PTFE lining is to serve as a continuous, impenetrable barrier. This simple concept has profound implications for valve performance and longevity.

How the PTFE Lining Works

The PTFE is applied either as a liner to the valve seat or as an encapsulation over the valve disc. This ensures that the flowing media—whether a harsh acid, a solvent, or purified water—never makes direct contact with the underlying cast iron, carbon steel, or stainless steel body.

This design effectively prevents the corrosion, rust, and chemical degradation that would otherwise destroy a standard metal valve in a demanding service environment.

Leveraging Material Plasticity for a Perfect Seal

PTFE is a relatively soft and pliable material. This plasticity is a key advantage, allowing the disc to press firmly into the seat when closed.

This tight fit conforms to any minor imperfections and creates an exceptionally reliable seal, often achieving zero-leakage performance where bubble-tight shutoff is critical.

Compensating for Material Weaknesses

While PTFE has incredible chemical properties, it lacks the structural strength to handle high line pressures on its own.

The metal valve body provides the necessary rigidity and pressure containment. This synergistic design allows the valve to operate in demanding industrial environments where a solid plastic valve would fail.

Key Performance Enhancements Explained

The integration of PTFE results in several distinct and measurable performance improvements over traditional all-metal or simple elastomer-lined valves.

Unmatched Corrosion Resistance

The PTFE lining makes the valve inert to a vast range of aggressive chemicals, including strong acids, alkalis, and oxidants. This makes it a go-to solution for chemical processing, pharmaceuticals, and other industries handling corrosive substances.

Wide Operational Temperature Range

PTFE maintains its properties across an impressive thermal spectrum. It remains effective and resilient in applications ranging from cryogenic temperatures (-196°C) up to high-heat processes (200°C).

Preventing Media Buildup

The surface of PTFE is famously non-stick, similar to its use in cookware. This low-energy surface prevents process media from adhering to or clogging the valve components.

This ensures a smooth, consistent flow and dramatically reduces the maintenance required to clean the valve's internal parts.

Reduced Friction and Easier Operation

PTFE has one of the lowest coefficients of friction of any solid material. This means the disc can rotate open and closed with minimal resistance.

The direct benefits are lower torque requirements for actuation (allowing for smaller, less expensive actuators) and significantly reduced wear and tear on the stem and seals over the valve's lifespan.

Understanding the Trade-offs and Limitations

While highly effective, the PTFE-lined design is not a universal solution. Understanding its limitations is crucial for proper application.

Pressure and Temperature Constraints

Although the temperature range is wide, PTFE can be compromised at the extreme upper limits when combined with high pressure. The material can soften, potentially affecting sealing integrity. It is critical to operate within the manufacturer's specified pressure-temperature curve.

Susceptibility to Abrasive Media

PTFE is a soft material. It is an excellent choice for clean, corrosive liquids and gases but is not well-suited for services containing abrasive particles, slurries, or solids. These can quickly erode or score the liner, leading to premature failure.

Installation Sensitivity

The integrity of the PTFE liner is paramount. Careless handling or improper installation, such as over-torquing flange bolts, can damage or deform the liner at the flange faces. This can create a leak path, completely negating the valve's benefits.

Making the Right Choice for Your Application

Selecting the correct valve requires matching its strengths to your primary operational goal.

- If your primary focus is handling highly corrosive chemicals: The PTFE-lined butterfly valve is an industry standard, offering superior protection against chemical attack at a lower cost than exotic alloy valves.

- If your primary focus is purity and preventing contamination: The non-stick, inert surface of PTFE makes it an excellent choice for pharmaceutical, food and beverage, or high-purity water applications.

- If your primary focus is operational efficiency and low maintenance: The low-friction, non-clogging design reduces actuation costs and cleaning cycles, extending the valve's service life with minimal intervention.

- If your primary focus is containing abrasive slurries: You should look for an alternative, such as a rubber-lined or knife gate valve specifically designed for abrasive service.

Ultimately, the PTFE-lined butterfly valve's design provides a high-performance, versatile, and cost-effective solution for some of the most challenging industrial fluid-handling applications.

Summary Table:

| Performance Feature | Benefit |

|---|---|

| PTFE Lining | Creates a barrier, isolating metal from corrosive media |

| Corrosion Resistance | Inert to strong acids, alkalis, and oxidants |

| Temperature Range | Operates from -196°C to 200°C |

| Non-Stick Surface | Prevents media buildup and clogging |

| Low Friction | Reduces torque, wear, and actuation costs |

| Tight Seal | Achieves zero-leakage, bubble-tight shutoff |

Need a reliable PTFE-lined valve for your demanding application? KINTEK specializes in manufacturing high-performance PTFE components, including custom seals, liners, and labware. Whether you're in the semiconductor, medical, laboratory, or industrial sector, we provide precision-engineered solutions from prototypes to high-volume orders. Contact us today to discuss how our PTFE expertise can enhance your system's performance and longevity!

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Customizable PTFE Seals Filter Holders for Versatile Applications

People Also Ask

- What are the advantages of using EPDM in wafer style and lugged butterfly valves? Superior Sealing for Water & Steam

- What advantages do PTFE valves offer in terms of friction? Achieve Ultra-Low Friction and Energy Savings

- Why are PTFE rotary shaft seals suitable for food and beverage processing? Ensure Purity & Performance

- What precautions should be taken when installing PTFE O-rings? Avoid Permanent Damage and Seal Failure

- In which industries are PTFE gaskets commonly used? Ensuring Safety & Purity in Demanding Applications

- What are PTFE gaskets and how are they made? A Guide to High-Performance Sealing Solutions

- What are some common alternatives to Teflon sheets for heat press applications? Find the Right Protective Sheet

- In which industries are EPTFE gaskets commonly used? Critical Sealing Solutions for Demanding Environments