In short, EPDM is the material of choice for wafer and lug style butterfly valves in water-based applications due to its exceptional resistance to water and steam, combined with its high durability and flexibility. These properties ensure a reliable, long-lasting seal in common systems like water treatment and HVAC, where it consistently outperforms other materials not specifically designed for these conditions.

The core decision comes down to the media flowing through your valve. EPDM is the industry standard for water and steam due to its superior physical resilience and sealing capabilities, but it should be avoided for applications involving harsh chemicals or hydrocarbon oils, where materials like PTFE are required.

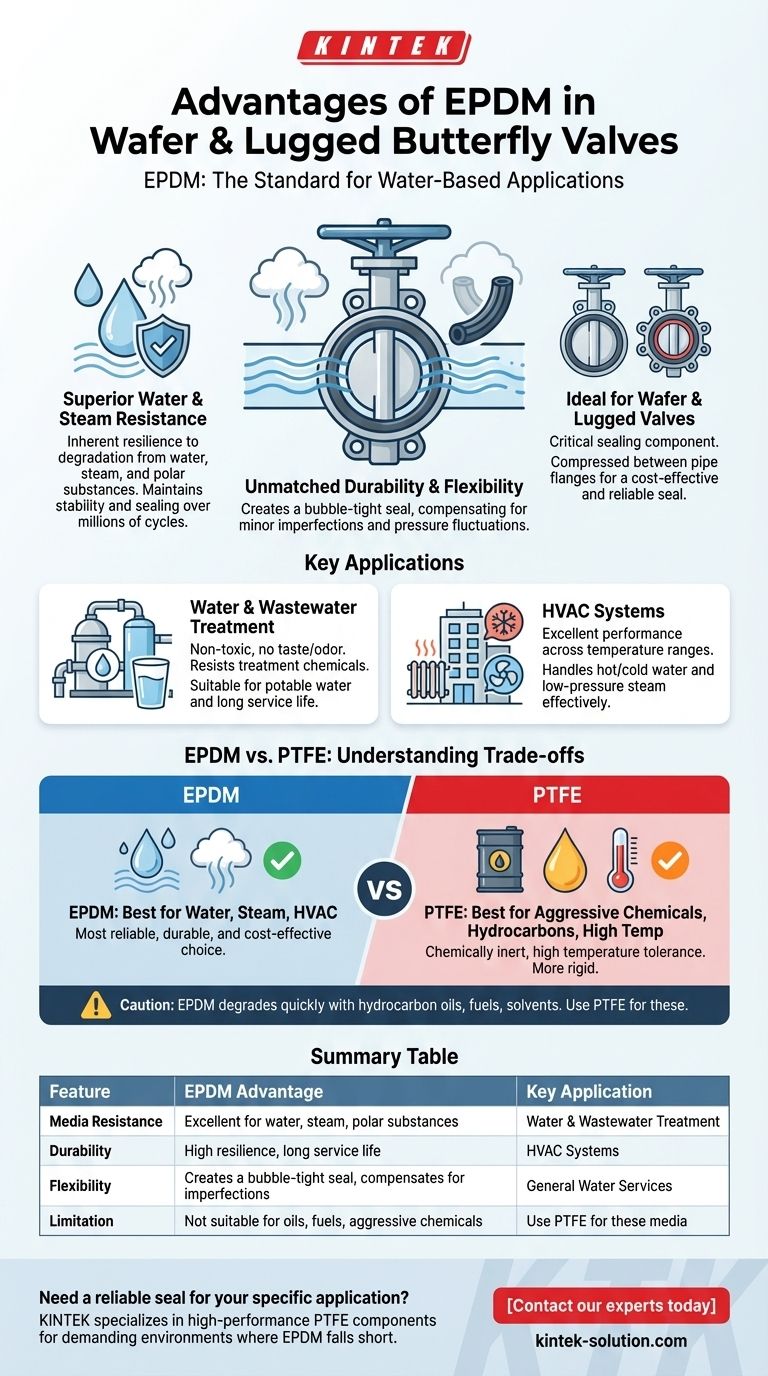

Why EPDM Excels in Water-Based Systems

The performance of a butterfly valve is fundamentally determined by the integrity of its seat. For wafer and lug style valves, the EPDM (Ethylene Propylene Diene Monomer) rubber seat offers a unique combination of properties tailored for specific, widespread industrial uses.

Superior Water and Steam Resistance

EPDM's molecular structure is inherently resistant to degradation from water, steam, and polar substances. Unlike other elastomers, it does not swell, weaken, or break down when in constant contact with these media.

This ensures the valve maintains its dimensional stability and sealing integrity over millions of cycles.

Unmatched Durability and Flexibility

EPDM functions as a highly resilient elastomer, similar to rubber. This flexibility allows the seat to create a bubble-tight seal around the valve disc and against the pipe flanges.

It can easily compensate for minor imperfections and pressure fluctuations within the system, preventing leaks and ensuring reliable performance.

Ideal for Wafer and Lugged Valves

In both wafer and lug style butterfly valves, the EPDM seat is the critical sealing component. Its ability to be compressed between the pipe flanges creates the primary seal, making it a cost-effective and highly reliable solution for these valve designs.

Key Applications for EPDM Seats

The specific advantages of EPDM make it the default choice in several major industries where wafer and lugged butterfly valves are common.

Water and Wastewater Treatment

EPDM is non-toxic and does not impart taste or odor, making it suitable for potable water applications. Its resistance to the various chemicals used in water treatment ensures a long and reliable service life.

HVAC Systems

Heating, Ventilation, and Air Conditioning (HVAC) systems constantly circulate hot and cold water or low-pressure steam. EPDM's excellent performance across a wide temperature range and its resistance to water make it the perfect material for these demanding environments.

Understanding the Trade-offs: EPDM vs. PTFE

Choosing the right seat material is about understanding its limitations. While EPDM is a superior choice for water, it is not a universal solution.

The Limitation of Chemical Resistance

The primary weakness of EPDM is its poor resistance to non-polar fluids. It will degrade quickly when exposed to hydrocarbon oils, petroleum-based fuels, solvents, and other aggressive chemicals.

Using an EPDM-seated valve in these applications will lead to rapid seat failure.

When to Choose PTFE

For applications involving harsh chemicals or extreme temperatures, PTFE (Polytetrafluoroethylene) is the appropriate choice. PTFE is nearly chemically inert and has a much higher temperature tolerance than EPDM.

However, PTFE is a more rigid material, which can sometimes result in less effective sealing in lower-pressure or abrasive applications compared to the flexible EPDM.

Making the Right Choice for Your Application

Selecting the correct valve seat material prevents costly downtime and ensures system safety. Your decision should be guided entirely by the media and operating conditions.

- If your primary focus is water, steam, or HVAC: EPDM is the most reliable, durable, and cost-effective choice for your wafer or lug butterfly valves.

- If your primary focus is aggressive chemical processing or high-temperature media: You must specify a material like PTFE to prevent catastrophic valve failure.

Ultimately, matching the seat material to the specific application is the most critical factor in ensuring long-term valve performance.

Summary Table:

| Feature | EPDM Advantage | Key Application |

|---|---|---|

| Media Resistance | Excellent for water, steam, polar substances | Water & Wastewater Treatment |

| Durability | High resilience, long service life | HVAC Systems |

| Flexibility | Creates a bubble-tight seal, compensates for imperfections | General Water Services |

| Limitation | Not suitable for oils, fuels, aggressive chemicals | Use PTFE for these media |

Need a reliable seal for your specific application?

At KINTEK, we specialize in manufacturing high-performance PTFE components, including custom seals and liners for demanding industrial, semiconductor, and laboratory environments. While EPDM excels in water-based systems, our precision PTFE solutions are engineered to handle aggressive chemicals and extreme temperatures where EPDM falls short.

We prioritize precision production and offer custom fabrication from prototypes to high-volume orders to meet your exact specifications.

Contact our experts today to discuss your valve seat or custom component needs and ensure optimal performance for your system.

Visual Guide

Related Products

- Custom PTFE and Nitrile Diaphragm Pump Components for Demanding Applications

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Customizable PTFE Seals Filter Holders for Versatile Applications

- Custom PTFE Microwave Digestion Vessels for Demanding Applications

People Also Ask

- What makes PTFE-lined diaphragm valves suitable for wastewater treatment? Ensure Reliability and Cost Savings

- What industries commonly use PTFE lined diaphragm valves and why? Ensure Purity & Corrosion Resistance

- What are the operational temperature limits for PTFE-lined diaphragm valves? Understanding the Full System Range

- What are the key properties of PTFE that benefit bellows and diaphragms? Achieve Unmatched Reliability in Harsh Environments

- What are the main technical features that influence the performance of PTFE diaphragms? Optimize for Durability & Chemical Resistance